Supplying and Increasing Production of High Quality Extrusion Meltblown Dies During Pandemic

This year the use of meltblown and non-woven fabrics has suffered an exponential increase on its demand, this due COVID-19 pandemic.

Taiwan has one key actor in the industry, GMA Machinery, experts in extrusion melt blown dies production, this being one of the main components in the fabrication of the heart medical masks, meltblown non-woven fabric.

In order to be able to cover the worldwide demand of its products, they have invested resources in research and development, increasing their production capacity, and working 24 hours a day if needed. GMA products quickly occupy a leading position in the local and international market, thanks to their production capacity, but also the outstanding quality that can be found on their products.

Reducing delivery time has been one of the key points for GMA, since most customers need the melt blown dies as soon as possible to start production or increase their capacity.

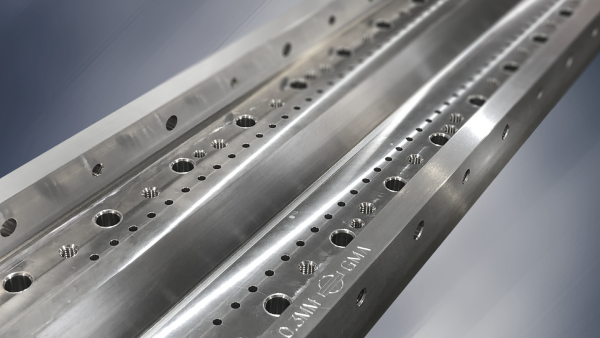

High quality Meltblown Dies.

For GMA quality is first, that is what makes them to be so demanded during pandemic, since one of the main applications during this year is medical masks.

To fill the highest quality standards, their processing methods are different, since for this kind of dies, small details make huge difference, in this case, if manufacturers want to have good quality and perfectly rounded through off the channel on their final products, every capillaries must be smooth, so the material doesn’t get stuck in the tiny nozzle, that is drilling by GMA custom made milling machines with GMA special design drill to accomplish 0.2-0.3mm diameter capillaries.

One of the biggest challenge and what makes different GMA takes care of small details, is well known the process to manufacture these devices is complicated, sometimes need over thousands of tiny capillaries to be drilled, during this process, that it can take hundreds of hours, With GMA high standard of roundness and surface roughness through out the channel for all the capillaries, there is zero tolerance for defects. If one of the capillaries out of thousand has not met their quality standard, they scrap the whole unit and start the whole process all over again.

If international customers are looking for high-quality supplier, paired comparable with Japanese and European producers, GMA is the best option, also can rest assured that any after sales inquire will be solved fast, this thanks to the importance and how serious GMA takes customer problems.

If you have any inquiry, please click the link below:

GMA EXTRUSION DIES

GMA EXTRUSION PERIPHERALS

GMA COATING EQUIPMENT

|

Official Website https://www.gmatw.com/index.html GMA in PRM-TAIWAN https://www.prm-taiwan.com/com/gma.html |