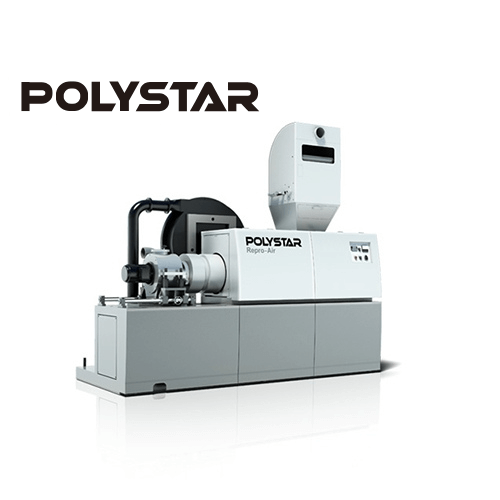

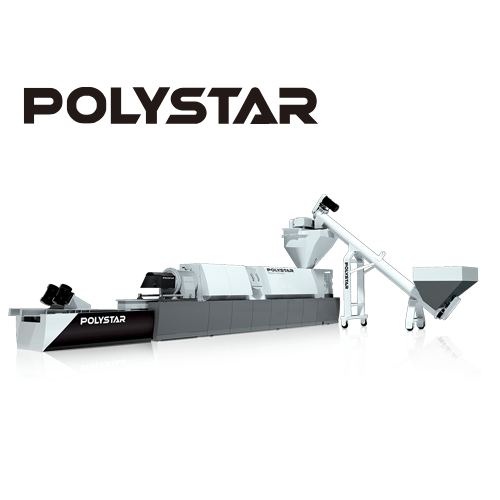

Recycling machine designed for processing up to 95% printed surface material.

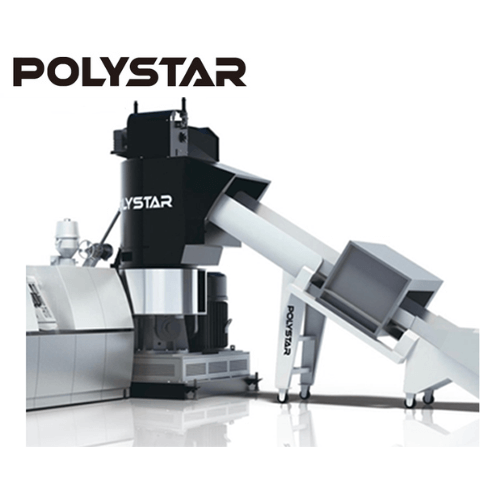

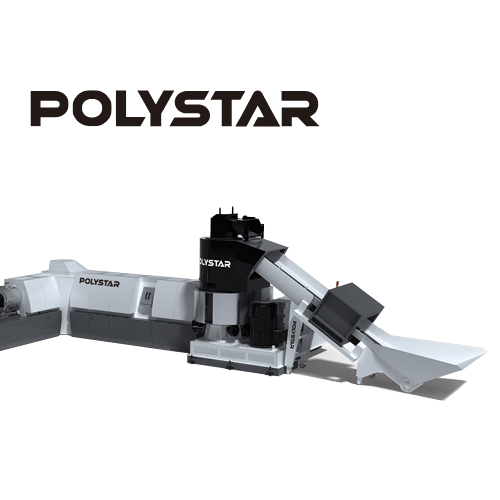

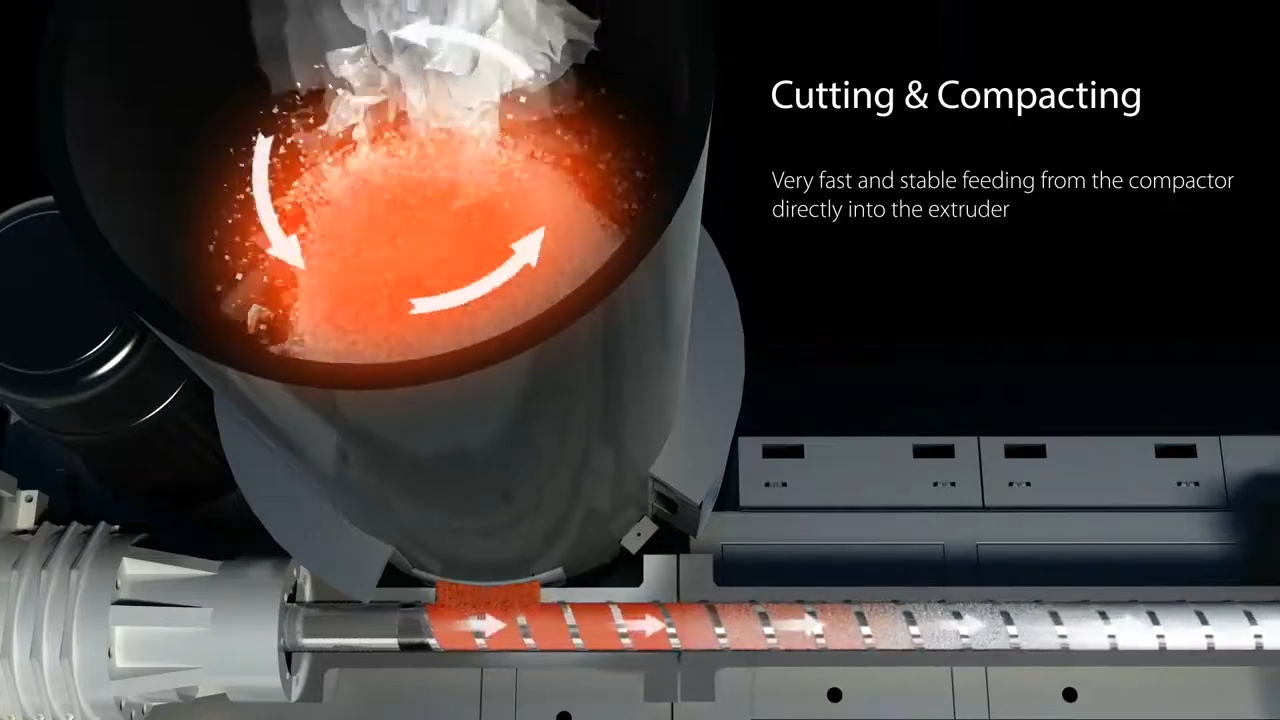

1. Improved cutter compactor for faster and more stable material feeding

- Very fast and stable feeding from the cutter compactor directly into the extruder

2. 10% less power consumption; 20% higher output; 100% pellets re-usability

- The pellets produced by the recycling machine can be put directly back into the production line, in most cases for blown film or pipe extrusion processes.

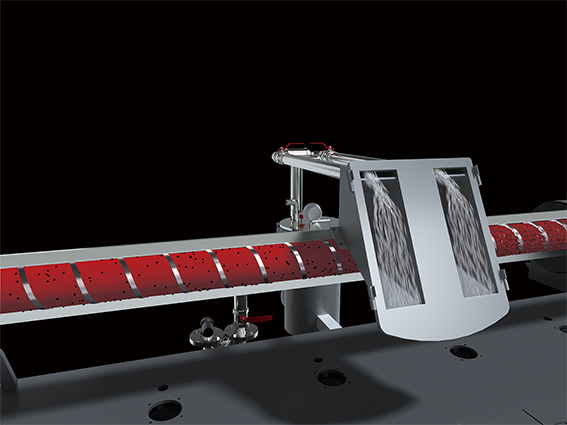

3. High efficient degassing connected with vacuum pump for environment protection

- Able to process both printed and non-printed material

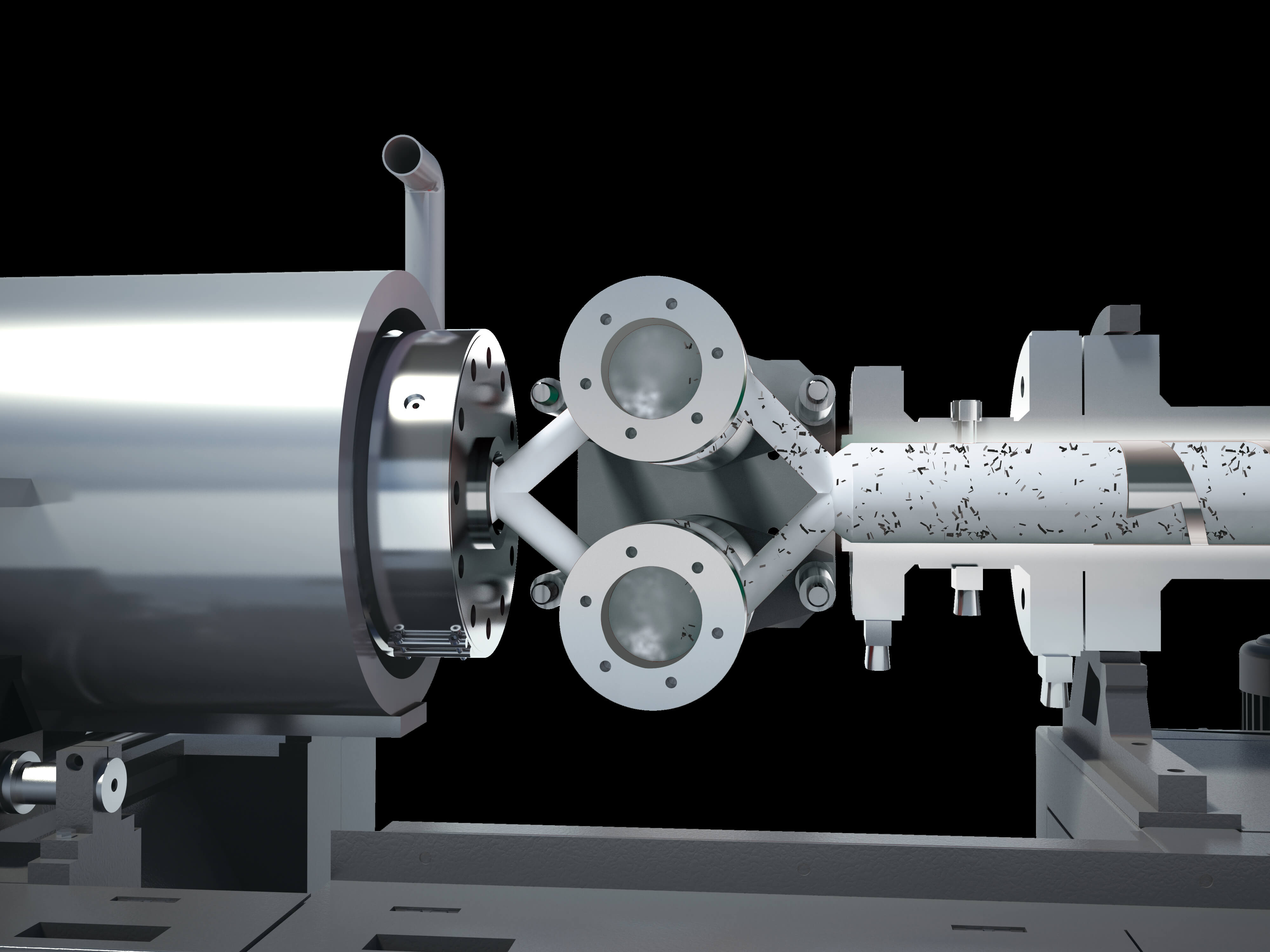

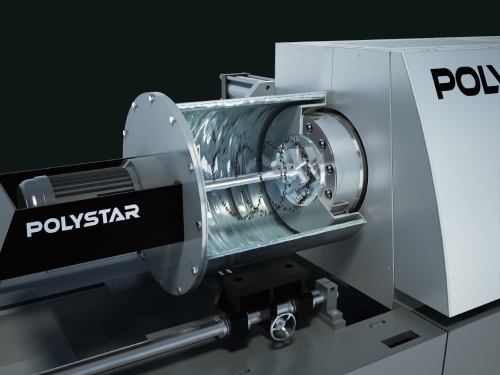

4. Non-Stop dual channel piston filtration system

- Filter with dual channel system for non-stop operation and reduces machine down time

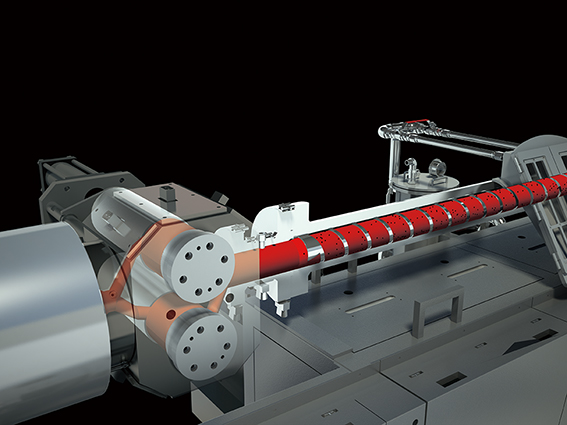

5. Automation Die face pelletizing technology for uniform pellets producing

- Produces high quality plastic pellets for reprocessing

6. Intelligent pressure detection and alarm control system

7. Elegant industrial design

8. Polystar Machinery is able to customize each section of machinery regarding to customer's need.

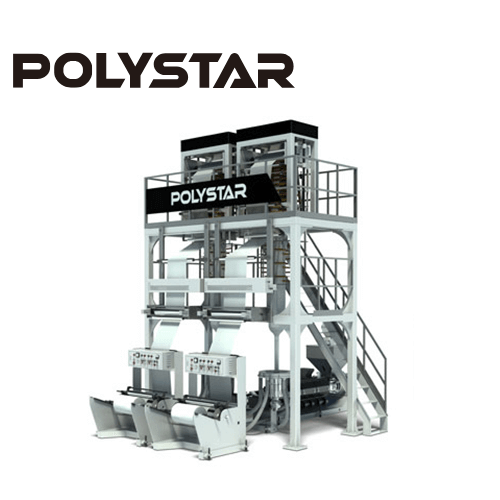

● Forma: película de embalaje, bolsas, sábanas, red, espuma, cintas, tejidos de PP / rafia, rebobinado de plástico, escamas, gránulos, restos, bordes recortados, copos de película lavada

● Tipo: HDPE, LDPE, LLDPE, PP, BOPP, PS, ABS, PU, PC

& nbsp;

1. Feeding System

- With belt conveyor: Feeding of scraps is easy and automatically controlled (the conveyor automatically starts/stops depending on theamount of material input)

- Film-on-rolls: Fed with nip roll feeder at the same time.

2. Cutting and Compacting

Cutter compactor with rotary knives & direct feeding to extruder :Cuts, dries and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

3. Degassing

Two-zone degassing (double-vented degasification) : Able to process films with larger printed area and some water content.

4. Filtration

Screen change with dual channel system: For non-stop operation and prevents material from leaking.

5. Pelletization

Hot die face pelletizer: Produces high-quality plastic pellets for reprocessing.

6. Recycled Pellets

The plastic pellets can be put directly back into the production line such as blown film extrusion and pipe extrusion.

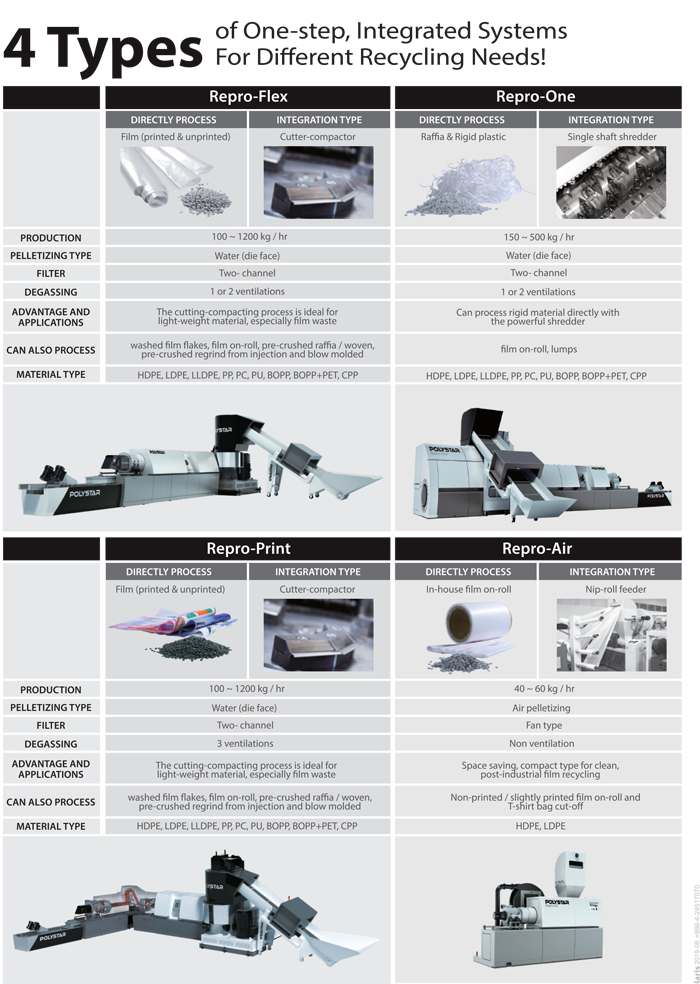

| Model Name | Repro-Flex |

| Final Product | Plastic pellets/granule |

| Machine Components | Conveyor belt, cutter compactor shredder, extruder, pelletizing unit, water cooling unit, drying unit, silo tank |

| Recycling Material | HDPE,LDPE,LLDPE, PP, BOPP, CPP, OPP, PA,PC,PS,PU,EPS |

| Output range | 100kg~ 1200 kg/hr *Based on post-industrial LDPE film clean, dry |

| Feeding | Conveyor belt (Standard), Nip roll feeder (Optional) |

| Screw Diameter | 65~180mm (customized) |

| Screw L/D | 30/1,32/1,34/1,36/1 (customized) |

| Screw Material | SACM-645 (Customized bimetallic screw) |

| Degassing | Single or double vented degassing, Unvented for non-printed film (customized)/ Two stage type (mother-baby extruder) for even better degassing |

| Cutting Type | Hot die face pelletizing (Water ring pelletizer) |

| Cooling | Water cooled |

| Voltage | Customized based on request (For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...) |

| Optional Devices | Metal detector(S+S) , Nip roller for film roll feeding , Additive feeder for masterbatch, Centrifuge dryer for drying |

| Delivery Time | 75~120 days for customized machine. In stock machines available |

| Warranty | 1 year |

| Technical Assistance | Engineers available to service machinery overseas |

| Modelo | HNT-65V | HNT-85V | HNT-100V | HNT-120V |

| Salida | 80 ~ 120 kgs / hora | 150 ~ 250 kgs / hora | 250 ~ 400 kgs / hora | 450 ~ 600 kgs / hora |

| 2,8 ton / día & nbsp; | 6 ton / día | 9.6 & nbsp; ton / día | 14.4 ton / día | |

| 84 ton / mes | 180 ton / mes | 288 ton / mes | 432 ton / mes | |

| Diámetro del tornillo | 65 mm | 85mm | 100 mm | 120 mm |

| Modelo | HNT-150V | HNT-165V | HNT-180V | |

| Salida | 700 ~ 800 kgs / hora | 850 ~ 1000 kgs / hora | 1000 ~ 1200 kgs / hora | |

| 19.2 ton / día | 24 ton / día | 28.8 ton / día & nbsp; | ||

| 576 ton / mes | 720 ton / mes | 864 ton / mes | ||

| Diámetro del tornillo | 150 mm | 165 mm | 180 mm |

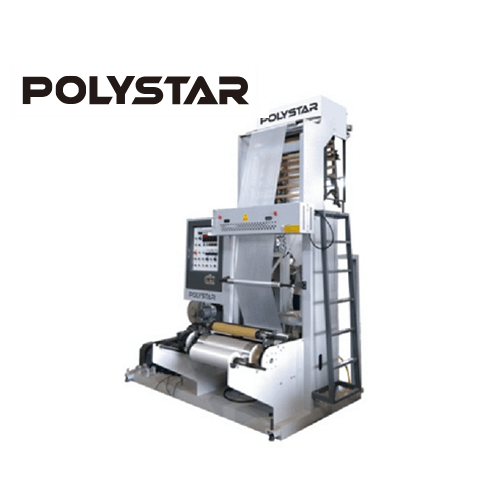

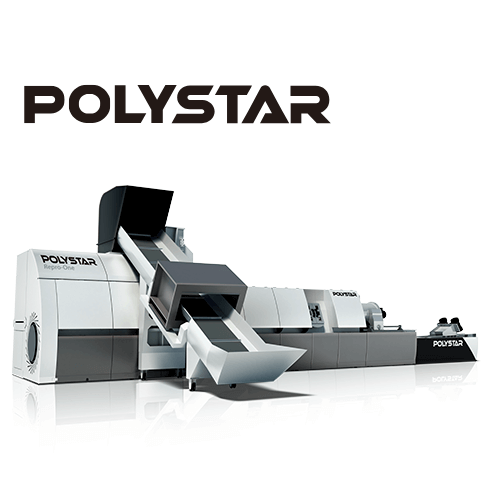

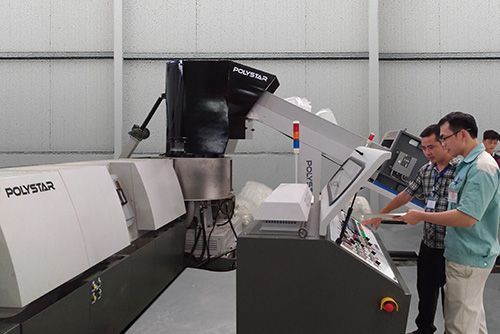

Fast machine delivery and simple installation -

Multiple sets of recycling pelletizing extruders Repro-Flex have been installed in South Africa in the year of 2020, mainly for film producers and bag converters of LDPE, HDPE, PP and BOPP who process their post-industrial (factory) waste in-house.

Fast delivery time is beneficial for customers

The two most popular models being delivered in the market are the 500kg/hr (Repro-Flex 120) and the 350kg/hr model (Repro-Flex 100) recycling pelletizers, which are suitable for film and bag producers who need to process different types of waste generated during the production process: film scraps, edge trim, film on roll, cut-off and start-up waste back into high quality pellets.

Since Polystar has completed its newest and largest manufacturing facility in Sinji industrial park (located in southern Taiwan) in early 2020, it has been able to shorten its previous delivery time by more than 75%. This third manufacturing site was built specifically to focus on the manufacturing and quality control of its recycling pelletizing lines.

Upon order confirmation, a standard Repro-Flex 100 or 120 machine can be delivered within 1~ 2.5 months. This allows the producers to receive the machines much faster and put them to work within the shortest time – without the need to wait for a typical 6 ~ 12 months and having their cash flow blocked.

Local service and support improved

In order to provide better and more in-time after-sale services, Polystar began working together with ZA Machinery, who has been in the South African plastic industry for more than 30 years with an experienced technical team. Following a successful exhibition together at Pro-Pak Johannesburg 2019, where a Repro-Flex 120 (500k/hr model) was on display and sold immediately, the sales have increased significantly since then.

Fast and simple installation

The compact design of the Polystar machine is much simpler, which can be installed within 2~3 days upon arrival. The recycling machines are disassembled into only three main parts for shipment, and once unloaded from the container can be quickly assembled again. Polystar provides fully detailed 3D explosive drawings (with each part clearly marked and labeled), as well as pre-recorded instruction videos of installation, start-up, operation, trouble shooting and regular maintenance videos in which the customers operators have full access by simply scanning a QR code from their mobile phones. The user-friendly design allows operators to quickly become familiar with the machine operation.

Lower cost on spare parts is a big plus

Apart from fast machine delivery and simple installation, the cost of consumable spare parts is also much less expensive comparing to its European competitors with comparable built quality. This can further reduce the overall production and maintenance cost.

Work with POLYSTAR

An experienced market leader in the recycling field, especially for the recycling of packaging film

More than 1,700 Polystar plastic recycling machines have been installed worldwide since 1988

Proven success and positive feedback from satisfied customers in 105 countries

Flexible, personalized machine design to meet your specific requirement and factory layout

Top quality components used for the machines: Energy saving and high performance motors

Cost-effective machine: Lower investment cost for a high quality and durable machine

Service and Communication

Source: https://www.polystarco.com/en/news_i_N2020091500001.html