JING DAY: The Best Customized Rubber Injection Machines for Automotive Parts and Components

According to rubber industry studies, it is expected that the rubber injection machine market will have a moderate growth during the present time to 2027. This is due to the changes occurring in the market, such as: fast production of rubber products, minimum wastage of material, low labor cost, and flexibility in material, color, and design.

HUARONG Launches Optimized Two-Platen Injection Molding Machine and Composited Injection Blow Molding Machine

Huarong is a Taiwanese manufacturer of injection molding machines for more than 40 years. "Industrial alliances create value for customers " as the core spirit for Huarong, being a worthy injection molding partner for customers is what Huarong insists on.

JING DAY: Automation of Rubber Injection Moulding Machines

While crowds cheer and television audiences tune in to watch professional athletes test their skills against one another, few will give any immediate thought to something as seemingly banal as rubber — but rubbers play a significant role.

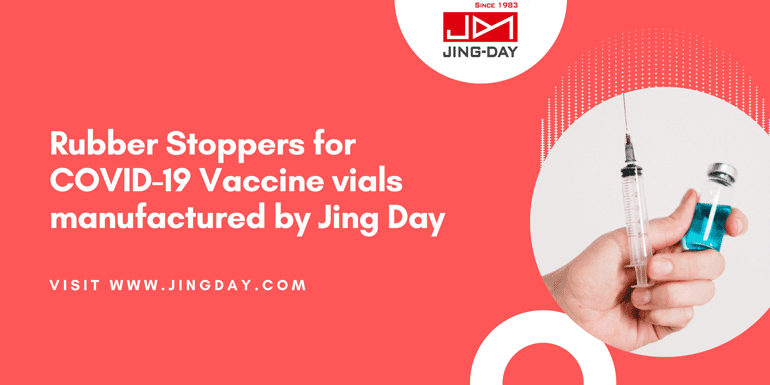

Rubber Stoppers for Vaccine Vials Manufactured by Jing-Day

There is no COVID-19 vaccination without those sterile rubber stoppers which seal each high-purity vaccine vial. These stoppers are being manufactured on special presses designed by Jing-Day Hydraulic Presses. In this year, suppliers of the international pharmaceutical industry awarded Jing-Day with a lot of order of these stopper presses.

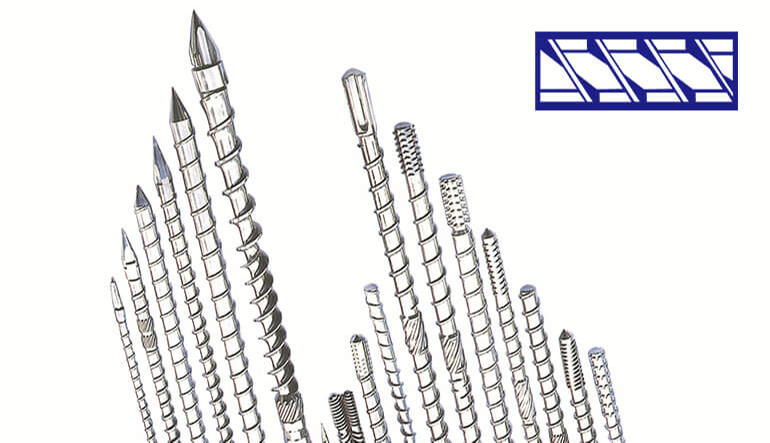

LUNG CHANG Cultivates the Trust of Manufacturers through Customized Screws and Barrels

During pandemic COVID-19 one of the biggest challenges for the plastic machinery industry is the travel and logistics limitations. No matter after sales services of the manufacturers are good, once it comes to the maintenance and part requirements, current transportation and logistics obstacles might cause the manufacturers delay in their business. Therefore, many plastic machine manufacturers prefer to use the parts, such as screws and barrels, that are high quality and meet customers' requirements precisely in their machines. In this case LUNG CHANG is one step ahead in the industry with its reliable extruder screws and barrels as well as injection molding machine screws and barrels.

JING DAY: Pioneer Silicone and Rubber Injection Molding Machines for Electric Vehicle Market

The sales of electric vehicles (EV) are increasing day by day in the world. Due to aiming to reduce greenhouse gas emissions for less polluted air, using electric vehicles is encouraged by governments worldwide through different types of financial measures, including tax and purchase incentives. This positively affects the global silicone and rubber market. The market size was valued at USD 971.8 million in 2017 and expected to observe an annual growth rate of 8.1% from 2018 to 2025 according to the report of Grand View Research.

JING DAY: Expert of Medical Silicone Rubber Injection Molding Machines

Recently, there is huge demand emerging for rubber and silicone molded products for medical device components due to the epidemic COVID-19, as well as the requirement in several industries

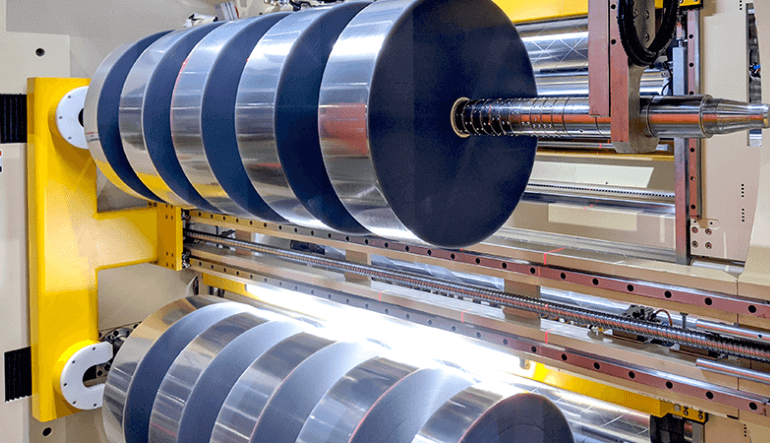

Flexible Packaging Film Slitting : Understanding Process and Select the Right Slitter

Flexible packaging is fundamental in providing protection and enhancing the visual appeal of consumer products. Central to the operations of this industry is the slitting process for flexible plastic films—which is a mechanism that significantly influences the efficiency and quality of the output.

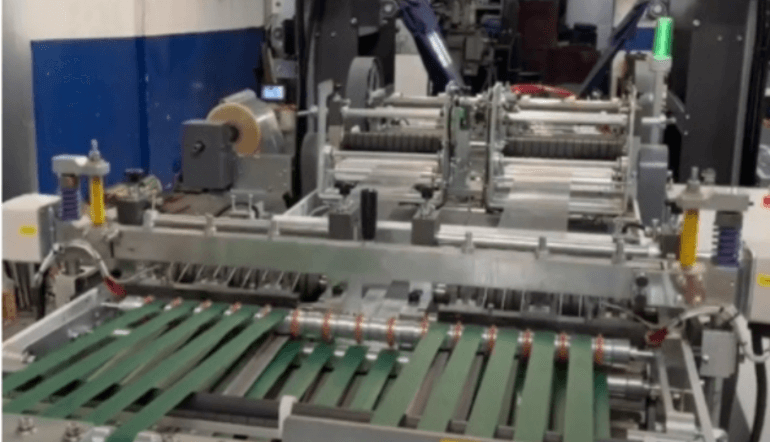

Plastic Bag Folding, Sealing & Cutting Combo Machine : Boost Your Efficiency with This All-in-One Solution

At World Steel Machinery, we understand that innovation drives success in the manufacturing industry. Our Plastic Bag Folding, Sealing & Cutting Combo Machine is an automated bag-making solution designed to streamline production by integrating plastic film folding, sealing, and cutting into one efficient system. This multi-functional packaging machine ensures faster, more efficient bag production, helping businesses reduce costs and increase output.

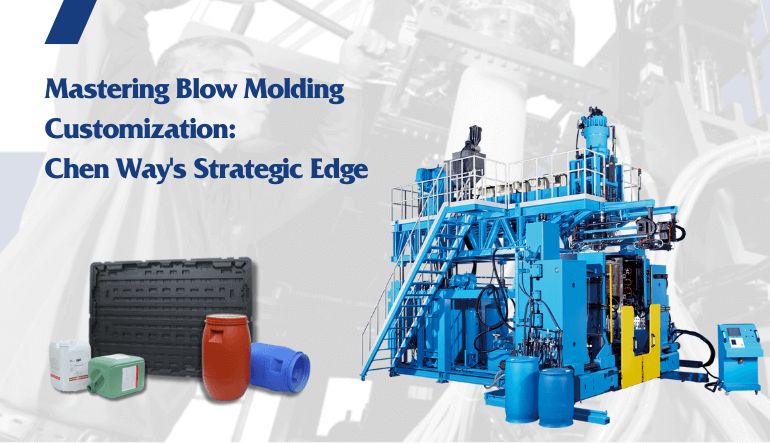

Mastering Blow Molding Customization: Chen Way's Strategic Edge

In the dynamic world of manufacturing, the ability to offer tailored solutions that meet specific client requirements is a significant competitive advantage. Chen Way Machinery (進韋機械), a leading player in the Plastic Blow Molding machinery sector, exemplifies this capability through its extensive range of products and exceptional customization services. This article delves into Chen Way Machinery's offerings, success stories, and the factors that make it a preferred choice for international machinery buyers.

TungYu: Revolutionizing the Industry and Shaping a Greener Future

TungYu, a name synonymous with innovation in the rubber industry, is thrilled to announce our participation in two of the most prestigious industry events: RubberTech 2024 in Shanghai, China, and TaipeiPlas 2024 in Taipei, Taiwan. At TaipeiPlas 2024, TungYu will be focusing on the theme of "Shaping a Greener Future of Sustainable Forming Technologies.

TungYu Servo Press: Revolutionizing Manufacturing with Sustainable Power

Are you looking to enhance your manufacturing processes while minimizing environmental impact? TungYu's advanced all-electric servo press offers a sustainable and efficient solution. By replacing traditional hydraulic systems with high-performance servo motors, our servo press achieves significant energy savings and a reduced carbon footprint.