Peletizadora De Plastico

HOT NEWS

Plastic Pelletizer Comparison for In-house Plastic Film Recycling

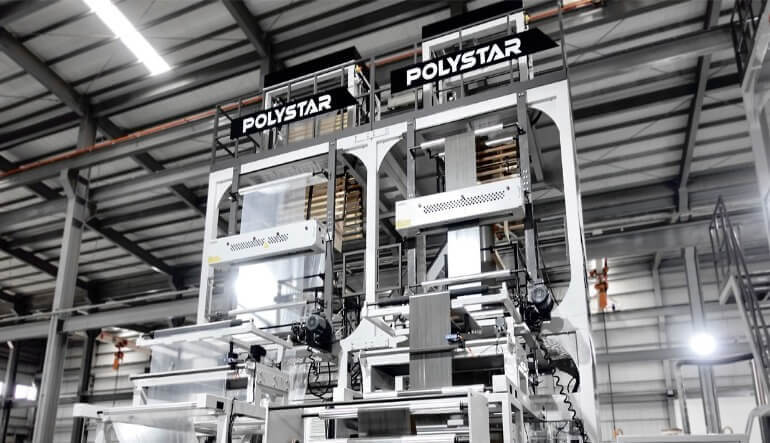

In-house plastic film is usually clean and can be reprocessed right away without extra procedures. But what kind of recycling equipment you should invest in to make the best use of it? For in-house plastic film recycling, POLYSTAR has two recommended solutions: the Cutter-compactor Plastic Pelletizer, Repro-Flex, and the Air-cooled Plastic Pelletizer, Repro-Air. Both recycling machines can process HDPE, LDPE, and LLDPE clean post-industrial plastics like film, bags, T-shirt bag cut-offs, and edge-trim waste. However, Repro-Flex can deal with more kinds of plastics such as PP, PS, PA, etc. Let’s take a closer look at what they feature and their advantages, which are the main differences between them.

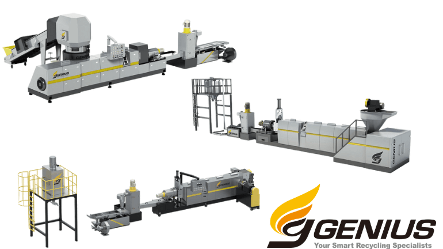

PARTICO: Your Best Plastic Recycling Partner in Taiwan

Partico Machinery Inc., which has over 25 years of experience in manufacturing and applying thermoplastics, is a professional manufacturer and developer of the thermoplastic recycling machine in Taiwan. Partico keeps improving ourself, we planning and designing a new factory building by ourself. The new factory is currently completed and in use, bringing higher quality services to customers.

Recycling for Post-consumer and Post-industrial Plastics on the Rise

It may be good for everyone to be in the plastic recycling business whether you are a recycler or a producer. New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste. With the great importance of recycled-based plastic products, the global demand for plastic recycling is expanding.

GENIUS: 5 Minutes to Understand Plastic Pelletizing Machine

Pelletizing plastics is the process that includes melting and cutting polymers into easy-to-handle plastic pellets. Understanding pelletizing system and feeding system will help you select the right plastic pelletizing machine! Pelletizers are the essential parts of plastic pelletizing machines. There are several types of pelletizing methods. Die face cutting system, also known as hot die cutting pelletizing system is the most popular used system among the other options.

3 Crucial Factors for a Complete Circular Economy

The production of plastic bags and plastic films around the globe is huge. In recent years, producers have implemented new technologies to complete a circular economy in their factories. To make this possible, producers need a plastic recycling system that produces good quality pellets and a blown film machine that can process up to 100% recycled plastic pellets.

POLYSTAR: How to Use Recycled Pellets in the Production Process - Post-consumer Waste

Plastic pellets are small granulates, used in Blown Film Machines, Injection Machines, Molding Machines, and other machines that produce plastic films, bottles, containers, bags, and more. These small pieces of material are the most important...

POLYSTAR: Recycled Plastic Pellets from PP Raffia and Woven Production – Tips to Reuse them Better

Which recycled plastic pellets should go back to PP tape extrusion line? On average, a 5-10% production waste is generated during the PP woven bag making process at different stages of the production: extruder start-up lumps, waste due to blockage in extruder die head, tape winding, circular loom (weaving defects), coating/lamination stage, pp woven/FIBC bag conversion and printing.

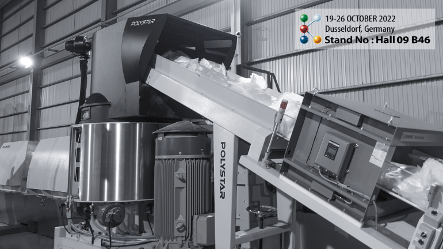

One-step Recycling for Raffia and Woven Producers

In general, 8% of production waste is generated during the process (from tape line production, looming and printing). The price of raw material is almost doubled comparing to the cost of having it recycled in-house. It would make sense for medium and large-sized Indian producers (who generate more than 30~40 tones of scraps per month or more) to recycle the production waste internally to reduce production cost.