2024 NPE Orlando Interview | ZERMA

In our first interview with Zerma, we had the pleasure of speaking to CEO, Max Paeslack about the innovative shredder they brought to NPE. Significantly, they also reveal the strategic reasons behind the decision to shift their development focus to Shanghai, China.

Solventless Laminating Machine (LM SF1300T) | WEBCONTROL

Webcontrol develops innovative solventless laminators with driven coating system and automatic turret unwind & rewind for high efficiency, consistent tension & minimum waste during roll changes.

2024 InterPlas Thailand Interview | SHINI

In this video, we have the pleasure of interviewing Siwakorn Tachapanich (Bank), the Sales Executive of Shini's local agent in Thailand. Shini boasts an exceptional sales and engineering team in Thailand, always ready to provide top-notch service whenever needed. Watch as we delve into their operations, commitment to customer satisfaction, and the unique advantages they bring to the market.

2024 TaipeiPlas International Plastics & Rubber Industry Show| CHUAN LIH FA

At the TaipeiPlas, PRM-Taiwan interviews CHUAN LIH FA MACHINERY WORKS CO., LTD. In this exclusive feature, CHUAN LIH FA demonstrates their latest custom-designed injection molding machines, highlighting innovations that push the boundaries of technology in the plastic injection molding industry. In this video, you'll learn how their new machines offer significant space-saving designs, as well as the ability to handle multi-color production, making them a versatile solution for manufacturers. Discover how CHUAN LIH FA is not only advancing technology but also fostering talent and driving progress in this dynamic industry.

Contribution to Circular Economy & ESG Implementation | GEORDING

In recent years, many manufacturers in the plastics industry have been aware of the environmental issues to reduce waste and protect our environment. GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well. Through the interview with the sales manager, Jessica Liu, she expressed the implementation of Reuse, Reduce and Recycle are core concepts to GEORDING. With the Refuse Derived Fuel production line, they could share the idea and provide assistance to lower greenhouse gas emissions. Supporting their customers is the priority of after-sale service. Even though the pandemic has been affecting the world, GEORDING still maintains an excellent relationship with customers by arranging video meetings and providing the service of remote tests. Therefore, they have been awarding the OEM cooperation with a long-term partner in Japan. One of GEORDING’s customers in Japan uses their RDF (Refuse Derived Fuel) to plant vegetables by using their equipment. As a result, we could tell that more and more manufacturers value the sustainability of ESG. 【Video Outline】 00:00 - Introduction 00:39 - Contribution to the circular economy 02:03 - RDF production line for ESG 03:06 - After-sales service for installation & maintenance 04:01 - OEM cooperation 04:39 - R&D developments 06:20 - Customer success stories 07:40 - Closing

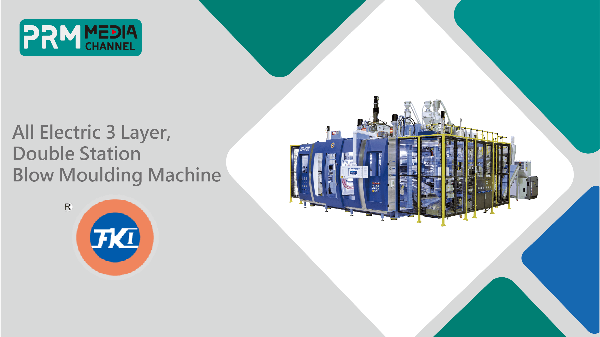

All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

All Electric 3 Layer, Double Station Blow Moulding Machine for plastic bottle making Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system. Product (Jerry Can) 15lt/20lt Product Weight (N.W) 550g/680g Product Rate 270bph Avg. Power Consumption 67kW/102A Service Circuit Breaker 211kW/320A Machine Dimensions (LxWxH) 10x8x4.4m More information, please visit us at: www.fki.com

Water Transfer Printing Dipping Machine | YHT

Since 1990, YHT has been a manufacturer for Printing High Definition Water Transfer Films, leading the way with short new pattern development time, quick lead time to turn around on film printing orders, and providing many solutions to qualify customers demands. We have been supplying films to many famous brand companies all around the world, and these work experiences have made us irreplaceable on Water Transfer Printing (WTP) business. We not only do printing films, but we also make relevant dipping and wash machines to supply a completed chain of product. 【Advantages of our Water Transfer Printing】 Color and design of the pattern through water pressure Decoration is possible for many sizes, shapes, and flexible products 【Applied Products】 Ski goggles, EVA shoes, electric switches, rifle scope, firearm, crossbows, dog leashes, home appliances, car panels, and steering wheels are all in the scope of WTP process.

Online and Offline Machinery Information for you! | PRM What To Say EP15

In this episode, we will uncover a series of online and offline information about machines and manufacturers related to the Plastics and Rubber Industry. Due to the pandemic many international exhibitions have been cancelled, postponed or even transformed into a digital exhibition. This has led us to become victims of the ones who attend international exhibitions. Nevertheless, for every challenging time there's always an opportunity to develop and become better. Following this philosophy we have brought a solution for the international companies in the related field who have been affected by the current situation. Check the video above to know more about the solutions we bring to the ones who are passionate about attending international exhibitions!

rPET Bottle for Household Packaging Solution | ChumPower

Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries. 【Product Appliance】 Beverages Water Edible Oil Daily-used Cosmetics 【Product Range】 One Stage Injection Blowing Machine Injection and Bottle Molding Manufacturing Stretch Blow Molding Machinery Sales / Turnkey Solution TS Series Models for Lower Production Output (Suggest to new market players) Linear PET Blow Molding Machine (Suggest to buyers who is looking for higher output) 【SS10-rPET Single-stage PET Bottle Blowing Machine】 Hybrid hydraulic system with an optimized clamping mechanism to ensure Energy Efficiency Barrier screw with venting capability can effectively lower the energy required for drying Adopt 4 station design Non-contact feature Reach the trending topics of ESG, Carbon Neutrality, and Net-Zero Emission

【K show 2022】Plastic Bag Making Machine | Bag On Roll Making Machine - PAL

PAL has decades of experience in Plastic Bag Making Machine manufacturing, and continues to develop, manufacture, and sell to all over the world, and even participates in exhibitions around the world.

Ultrasonic Metal Welding Machine-ULTRA6200-M-WT | MING JILEE

ULTRA6200-M-WT Ultrasonic Metal Welding Machine

Quick mold change system|QMCS|for Injection molding|Sistemas de cambio rápido del molde|FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds. Quick Mold Change Systems can rapidly transform your workshop, allowing for easy changeover for small batches, reduced labor costs and reduced stock holding. Coupling this system with a Mold Cart System will allow for fully automatic mold changing, further increasing the efficiency and productivity of your manufacturing operations. When installing a Quick Mold Change System for your injection molding and mold casting operations there are a number of direct and indirect benefits. Review the following table to see an overview of all of these benefits. Indirect Benefits Die Standardization Press Standardization Increased Safety Improved Working Environment Increased Competitiveness Direct Benefits Reduction in Die Change Time Efficient Small Batch Runs Reduced Stock Handling Higher Productivity and Quality Reduction in Labor Costs