Bag Making Machines for Multiple Applications | WORLD STEEL

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, World Steel is dedicated to making technological innovations and manufacturing packaging machines. The company has one of the best engineering crews in the industry to provide total solutions which include design, customization, and development. If you are looking for machines that produce, flower sleeves, diaper bags, book sleeves, self-adhesive bags, handle bags, sandwich bags, or more, then World Steel is one of the best choices for you.

Extrusion die and peripherals manufacturer | GMA

Founded in 1989, the GMA Machinery Enterprise Co., Ltd. (GMA), an R&D team composed of senior design engineers and technicians with decade’s strong experience in sheet and film extrusion equipment and auxiliary parts, has been devoted to providing custom products based on customer requirements. With 30 years of continuous efforts, it is the one of the best manufacturer in the world. Based on comprehensive processing equipment, GMA is able to exercise strict quality control throughout the whole in-house process from product design, manufacturing, assembling and inspection which, in turn, has earned customers’ continuous recognition and praise.

Vacuum Molding Machine | LIN CHENG

Vacuum Molding Machine - Oil Seal Vacuum Molding Machine- LIN CHENG Specializes in Vacuum Molding Machine, Lin Cheng Technologies Co., Ltd. was established in 1978 and has a strong professional team to manufacture Vacuum Molding Machine. A series of services we can provide ranges from the purchase of machines to the design and development of molds. Our Vacuum Molding Machine products are used for electronic components, car parts, oil rings, and so on. In 1997, we were granted the ISO 9002 quality certification.

ABA Blown Film Machine (JC-ABA) | PLASCO

PLASCO's JC-ABA Series of 3-layer co-extrusion blown film lines are the ultimate economic and environmental solutions for multi-layer blown film production. 【Machine Spec】 Applicable Material: LDPE / LLDPE / MDPE / HDPE Screw Diameter (mm): "45/55", "50/55", "55/75" Film Layflat Width (mm): 800 / 1000 / 1200 Film Thickness (mm): 0.015-0.10 Extrusion Capacity (kg/hr): 100 / 160 / 250 【Application】 Express Bag Plant Bag Shopping Bag T-shirt Bag Laundry Bag Garbage Bag 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Full Electric PK-95CD-E (PE) (Toggle) Single Station Double Heads Blow Molding Machine | PARKER

PARKER PK-95CD-E (PE) (Toggle) Single Station Double Heads Blow Molding Machine

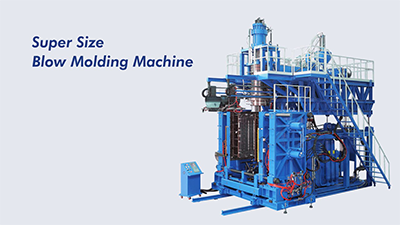

Blow Molding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. [Products List] + Small Blow Molding Machine + Medium Blow Molding Machine + Medium Co-extrusion Blow Molding Machine + Large Blow Molding Machine + Supersize Blow Molding Machine + Double L-Ring Drum Blow Molding Machine + Semi-auto Stretching Blow Molding Machine

Flexo Printing Machine Stack Type - Double Side 2+2 | ROTOFLEXO

ROTOFLEXO Stack Type Flexo Printing Machine - 250 M MIN - Double Side 2+2 - High precision cylinders, anilox rollers, and guiding rollers - Automatic temperature control system - High precision gear transmission system - Closed chamber doctor blade system - Automatic tension, edge, and web guide control - High speed forward and reverse printing desk motion - High precision ball screw designs for key components - Motorised horizontal and longitudinal registration system - Electric heat/drying system - CNC desk position control

PVC Medical Tube Extrusion Machine Line (High speed type+Dust proof) | Everplast

The medical tubes produced by Everplast's medical tube extrusion machines have excellent quality and accuracy. They use advanced manufacturing technology and precision machining processes to ensure that each medical tube has accurate dimensions and uniform texture, complying with the strict standards and standards of the medical industry. specification. Whether used for infusion, drainage, or other medical applications, these tubings provide reliable performance and safety. Meets the strict quality and specification requirements of the medical industry. *Contact Info: Web: https://www.everplast.com.tw/ Facebook: https://reurl.cc/r1LZb YouTube:https://www.youtube.com/channel/UC_ziI3cDyRGjV71s8YkV-pg 1.https://www.everplast.com.tw/product/machine-line/medical-tube-machine-line/ 2.https://www.everplast.com.tw/product/machine-line/ 3.https://reurl.cc/QeMrp0 Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

2024 TaipeiPlas International Plastics & Rubber Industry Show| TienKang

In this exclusive interview at TaipeiPlas, I meeting with Daniel from Tien Kang to discuss their groundbreaking new technology that utilizes 100% recyclable pellets. Daniel also shares insights into the various materials they use, including EVA, SEBS, TPU, TPEE, and PEBAX, to create the perfect in midsoles and outsoles . Watch to learn more about how Tien Kang is pushing the boundaries of innovation in sustainable footwear production! #TaipeiPlas #TienKang #SustainableTechnology #RecyclablePellets #Insoles #FootwearInnovation

Waste Material Recycling Equipment at K 2022 | GENOX

It was a great honor for PRM-Taiwan to invite Jamie Jiang — the Marketing Director from GENOX. In the interview, we talked about the macro economic market during the pandemic, and the forecast for the future. In the end, Jamie also mentioned that the K Show is a worldwide exhibition for partners from the Plastic & Rubber industry, people can gain the newest industry information at the show.

Gravimetric Technology at K 2022 | MAGUIRE

Founded in 1977, Maguire Products manufactures gravimetric blenders and feeders, volumetric feeders, ULTRA low energy dryers, conveying systems, extrusion control systems, loss in weight extrusion control, and related auxiliaries for Plastic & Rubber industry. It was a great honor for PRM-TAIWAN to invite Frank Kavanagh — Vice President Global Sales and Tony Tsai — Sales Manager (Taiwan) from Maguire. The conversation was mainly about the biggest challenge during the pandemic and how to integrate product innovation into application of Circular Economy, Digitalization, Climate Protection, which was the 3 main topics of K 2022. In the end, Mr. Kavanagh also talked about their main goal of the attendance. For more information, check the video!

Donghua Machinery's High-precision All-electric Machine for Medical Applications Debuts, Chemical Foaming Promotes Automotive Lightweighting (Chinese Interview)

Donghua Machinery Ltd. is a subsidiary of Cosmos Machinery Ltd., the Hong Kong joint venture enterprise for manufacturing full-automatic computer-controlled injection moulding machines and auxiliary equipment. Donghua was founded in 1986, Donghua can provide a whole set of injection moulding machine and its auxiliary equipment to customers on turnkey basis, with 43g to 300,000g injection volume, 25T to 4,000T clamping force, totally in over 90 models with various design specifications. The yearly output capacity is over 5,000 machines.

Leading Global PEEK Company Victrex Reinforces The Presence and Capacity for China and Asia

Victrex is an innovative world leader in high-performance polymer solutions, focused on the strategic markets of automotive, aerospace, energy, manufacturing & engineering, electronics and medical. Every day, millions of people use products and applications, which contain our materials from smartphones, aeroplanes and cars to oil and gas operations and medical devices. With over 40 years experience, we develop world leading solutions in PEEK- and PAEK-based polymers and selected semi-finished and finished parts which shape future performance for our customers and our markets.

Jwell's high-speed and high-efficient blow molding technology accelerates packaging development (Chinese & English Interview)

SUZHOU JWELL PLASTIC MACHINERY CO., LTD. Suzhou Jwell blow-molding machinery is another important strategic development center of Jiangsu Jwell plastic Machinery Co., LTD, located in Suzhou Taicang FOSHAN BEKWELL INTELLIGENT EQUIPMENT CO.,LTD. Foshan Bekwell Intelligent Equipment Co.,Ltd. is another important development strategy center of Shanghai JWELL Machinery Co.,Ltd. Locating at Lunjiao sireet Shunde district Foshan City,a high-tech manufacturer specializing in research and development of plastic extrusion equipment. The factory area is of 30 acres, more than 100 staff and 20 technical and management employees; We have a high qualified R&D and experienced mechanical and electri-cal engineer team as well as advanced processing foundation and normative assembly shop. We supply more than 200 sets lines annually. Our enterprise spirit is "Attentive, Enduring, Quickly and Orderly", keeping on exploring of new extrusion field. Mostly welcome to new and old customers to visit us for investigation, guidance and cooperation. We are happy to offer powerful support!

Haitian Shows Machines for All-electric and Thin-wall Injection Molding Trends (Chinese Interview)

HAITIAN INTERNATIONAL HOLDINGS LIMITED Haitian International Holdings Limited develops and produces the international machine concept of the 21st century. Our sophisticated product portfolio of injection molding machine construction covers the entire spectrum of the plastics processing industry and meets the most diverse customer demands for the manufacture of mass and high-precision plastic products.

Yaodong Machinery Highlights Packaging and Printing Integration for High Efficiency and Low Cost Benefits (Chinese Interview)

Yaodong Machinery Manufacturing Co., LTD is a high-tech enterprise that specializes in designing and manufacturing automatic screen printing machine, hot stamping machine and the peripheral equipments related. The R&D Team is over 20 years industrial experience, adhering to expertise, efficiency, honesty, win-win is our philosophy, committed to create value for customer and offer comprehensive solution. Professional technology leads to our success; we will continue to innovate to promote the automation and intelligence of products, fully integrating auto loading, flame detection, CCD registration and detection, UV intelligent management, temperature and humidity synchronization monitoring and other function modules, continuous to provide high quality, stable and high performance products and supporting solution. “Advanced technology, quality first, service superior” is the central theme to win the reputation. We have serviced to lots of famous brand domestic and abroad, such as P&G, Amore Pacific, Unilever, LG, Loreal, Henkel, Kao, NIVEA, Reckitt Benckiser, Avon, Johnson & Johnson, Shiseido, Mentholatum, Pechoin etc..

Increase of orders: Jwell promotes new plates, sheet and film equipment (English & Chinese Interview)

CHANGZHOU JWELL PLATE & SHEET EQUIPMENT TECHNOLOGY CO., LTD CHANGZHOU JWELL PLATE & SHEET EQUIPMENT TECHNOLOGY CO., LTD. is one more important strategic center and production base of JWELL Group.As the leading enterprise in plastic sheet machinery industry,. It is a company be specializing in manufacuturing optic sheet and waterproof sheet extrusion equipments.We have different department which include technical d, this new factories are equipped with a lot advanced CNC machining centers and well-organized assembling workshops. Every year, there will be more than 800 intelligent extrusion equipments manufac tured from this production base.Changzhou Jwell Sheet & Film Equipment Co.,Ltd is focus on manufacturing Sheet & Film extrusion equipments, complete and professional technical service, we are dedicated to offering Customized extrusion equipments for our global customers. Rigorous technical design, Strict and standard production process, complete after-sale service and maintenance system, ZHEJIANG JWELL is providing high-efficiency,energy-saving, outstand ing-quality extrusion eqipments and caring service to our customers. CHANGZHOU JWELL CHEMICAL MACHINERY CO., LTD. CHANGZHOU JWELL CHEMICAL MACHINERY CO., LTD. is a professional company of Jinwei machinery with the main business of parallel twin-screw. For many years, CHANGZHOU JWELL CHEMICAL MACHINERY CO., LTD. has been committed to the production and research and development of co rotating parallel twin-screw main machine and supporting auxiliary machine, and has achieved the same level in the application of polymer materials, such as all kinds of high filling granulation, PET bottle and other recycling granulation, PLA / PBAT modification and filling granulation, polyurethane / TPU reactive extrusion granulation and other mainstream technologies required by market application Head to head and ahead in some technologies. SUZHOU JWELL MACHINERY CO., LTD. Suzhou Jwell Machinery Co., Ltd. is an important development strategy center and manufacturing basement under the JWELL GROUP. It is located in Chengxiang Industrial area, Taicang, Suzhou City, 30 minutes far from Shanghai Hongqiao Airport. It covers an area of 20 hectares, and the workshop area is 120000 square meters, equipped with CNC machines and standardized assembly workshop. More than 1000 employees, with high-quality design and R & D team and experienced mechani cal and electrical commissioning engineer team. The company focuses on the manufacturing of the plastic pipe extrusion equipment and the full range of professional and technical services and turnkey project, making top quality plastic extrusion equipment to the customers of the world, which accounts for more than 75% is export. Strict design, strict standardized manufacturing process, perfect after-sales service guarantee system, provide customer with high efficiency, energy saving, excellent quality extrusion line and intimate service.

Victor Machinery Launches All-electric IBM Machine with World's First Full Circle In-mold Labeling (English & Chinese Interview)

Jiangsu Victor machinery co., LTD., is a collection research and development, production, sales and service in the integration of science and technology innovation enterprise.Main products injection blow molding machine and precision mould, plastic extrusion sheet production line, ptfe extruding production line.As a professional plastic packaging processing equipment suppliers, Victor machinery has been committed to become the trustworthy partner for customers, provide the comprehensive consummation production solutions.

Three Systems for Thermoforming Machines - CHUDONG | CHINAPLAS 2021

PRM Media Channel continues with this great cooperation we began with CPRJ, the official media group of CHINAPLAS, providing insights about Taiwanese experts in the Plastic and Rubber Industry. In this specific case, we had the great opportunity to interview one of our special actors in the Thermoforming Machinery Industry who will give us some great insights of the related industry. CHUDONG Machinery is a professional manufacturer with more than 35 years of experience in manufacturing & developing thermoforming technology and services in forming, cutting, and stacking in one place. The core for growth and success according to CHUDONG is having a strong R&D that can create specific systems to different markets. In this video, our PRM Director Alice will be carrying this interview with President Chester Chen & Vice-President Sophie Lu from CHUDONG Machinery Company. In the following President Chester Chen & V.P. Sophie Lu will be covering more about the three systems for air pressure thermoforming machines for the European, Japanese, and Asian markets: 1. Three Systems for Thermoforming Machines 2. Key Factors for Product Development 3. Differences between these Three Thermoforming Machine Systems 4. 2021 Innovations and Developments 5. CHINAPLAS Exhibition 2021

HSIN LONG Blown Film Die Heads | CHINAPLAS 2021

PRM Media Channel is very glad to announce the great cooperation with CPRJ, the official media group of CHINAPLAS. For this great opportunity, we bring you one of our special actors in the Blown Film Die Head Industry to share with us important facts & insights into the industry, and how their expertise reflects an outstanding performance on customer service, manufacturing process, and quality field. With half a century of rich experience in manufacturing, HSIN LONG is mainly specialized in producing Blown Film Dies and related components. These components can be applied in Packaging Films, Barrier Films for food packaging, Technical Films for high-tech applications, Sealing Films, Agricultural Films, Medical Films, Shrink and Stretch Films, TPU Films, Biodegradable Plastic Bags / Green Plastic Bags, and many more. In this video, our PRM Marketing Specialist Billy will be carrying the interview with the Special Assistant to the GM, Sandy from HSIN LONG Thread Rolling Co.

How to select anti-blocking agent for plastic masterbatch? --Please keep these 4 points!

Homsil special silica for plastic masterbatch is a mainstream and high-effective anti-blocking additive. It gives excellent performance to PP/PE/PET/POF and other plastic material anti-blocking masterbatch, co-made film by the masterbatch carrier. Widely used to Aluminized film, cigarette packaging film, heat shrinkable film, fruit bagging film, general packaging film, etc..Comply with FDA regulation, REACH regulation and other relative food contact requirements. Safe and healthy!