2024 InterPlas Thailand Interview | Chang Horing

We had the pleasure of interviewing Chang Horing Rubber Group, a leader in the rubber compound industry with over 20 years of experience, at Thailand InterPlas 2024. In this engaging conversation, they shared their expertise in developing and customizing rubber compounds for various industries, including automotive, chemical, heavy-duty, food, and water sectors. Chang Horing's dedication to quality and precision is evident in their state-of-the-art facilities, equipped with advanced systems and instruments to ensure high-quality consistency. They also discussed their future plans and initiatives related to Environmental, Social, and Governance (ESG) practices, highlighting their commitment to sustainability and innovation. We thank Chang Horing Rubber Group for sharing their valuable information and look forward to seeing their continued success in the industry.

Plastic Inflation Machine | KANG CHYAU

Plastic Inflation Machine - Twin Head HDPE Plastic Inflation Machine-Kang Chyau Specializes in Plastic Inflation Machine. Since its founding in 1988 Kang Chyau Industry has worked constantly to bring out new and innovative Plastic Inflation Machine products and offer customers a wide range of choices. After more than a decade of work our products are now sold in 62 countries around the globe, a true measure of our success in the Plastic Inflation Machine market.

VDMA Interview | Insight into the European Plastics & Rubber Market

We are excited to share the interview with Mr. Florian Mikulasch from Germany, who is the Marketing Analyst of VDMA (German Mechanical Engineering Industry Association). Mr. Mikulasch shared a clear insight into the German and European Plastics & Rubber Market, the current problems due to the pandemic, the second lockdown in Germany, and the solutions that companies and associations bring to life to ease the effects of the pandemic. Welcome to add comments and ask your questions in the comment section. Also, let us know about the video interviews (Such as which market?) that you would like to see on PRM Media Channel.

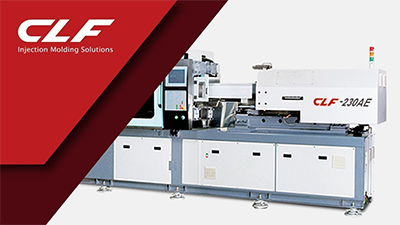

PET Preform Injection Molding Machine | CLF

PET Preform Injection Molding Machine for making big, medium and small mouth PET preform. CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle. Contact Information: https://www.clf.com.tw/en/contact.html

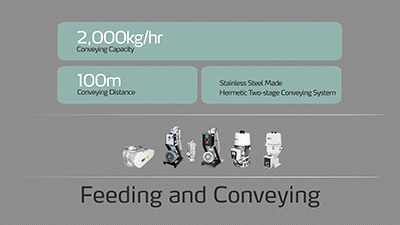

Plastic Dryer, Hopper Loader, Gravimatric Blender | SHINI

Plastic Dryer, Hopper Loader, Gravimatric Blender - Products Overview -Shini Specializes in plastic dryer and hopper dryer. SHINI PLASTICS TECHNOLOGIES, INC. products including hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chillers, sprue picker, side entry robot,gantry robot and more. The Shini Group, Originate from Taipei, Taiwan since 1969. Five manufacturing bases and one corporate technologies center around the world. World class manufacturer of plastics auxiliary equipment. For 41 years, Shini people adhered to the management principle of Focusing on Particular Business, Pursuing to be the World Leader which created new era and achieved many progresses. Shini Group has now become a world-class manufacture of plastic dryer, hopper dryer, hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chiller, sprue picker, side entry robot, gantry robot.

ChenHsong CFO Dave:Technology Innovations and Market Insights in Turkey | PlastEurasia Istanbul 2024

At PlastEurasia Istanbul 2024, ChenHsong CFO Dave discusses the company’s long-standing presence in the Turkish market and their latest technological innovations. Dave shares insights on the newest machines domestrate at the event and offers expert views on market direction and industry trends, particularly in the Turkish and regional plastics markets. Watch to learn about ChenHsong's cutting-edge technology and the future of the industry. Like, share, and subscribe for more industry insights!

2024 NPE Orlando Interview | ZERMA

In our first interview with Zerma, we had the pleasure of speaking to CEO, Max Paeslack about the innovative shredder they brought to NPE. Significantly, they also reveal the strategic reasons behind the decision to shift their development focus to Shanghai, China.

Online and Offline Machinery Information for you! | PRM What To Say EP15

In this episode, we will uncover a series of online and offline information about machines and manufacturers related to the Plastics and Rubber Industry. Due to the pandemic many international exhibitions have been cancelled, postponed or even transformed into a digital exhibition. This has led us to become victims of the ones who attend international exhibitions. Nevertheless, for every challenging time there's always an opportunity to develop and become better. Following this philosophy we have brought a solution for the international companies in the related field who have been affected by the current situation. Check the video above to know more about the solutions we bring to the ones who are passionate about attending international exhibitions!

Quick Die Change System | FORWELL

Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop. The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management.

MOLD TEMPERATURE CONTROLLER, YANN BANG

YANN BANG, Patented Mold Temperature Controller, Temperature Controlled Unit Our temperature control unit can use water/oil heating system to secure the high quality of plastic production made by injection, extrusion and blow molding machines. Learn more: https://www.yannbang.com/mold-tempera...

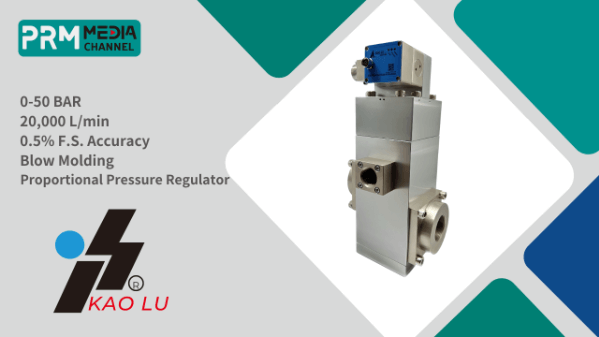

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | KaoLu

Product Description The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation. Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design. For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc. Applications for Electronic Pressure Regulators Spraying/ Painting Air Blowing Leak Testing Filling Pressure Artificial Heart Laser Cutting FAQ session – Proportional Electronic/Digital Pressure Regulators What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge? They are the same products with different names. Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc. Is the pressure regulator resistant to dirt? No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm. Any restriction on mounting orientation? Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag. Knowledge Base How Does a Proportional Pressure Regulator Work? A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control. Uses of Regulators Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications. The Working Process: Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static. When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal. Please check our video on: GennDih Enterprise. Co. Ltd

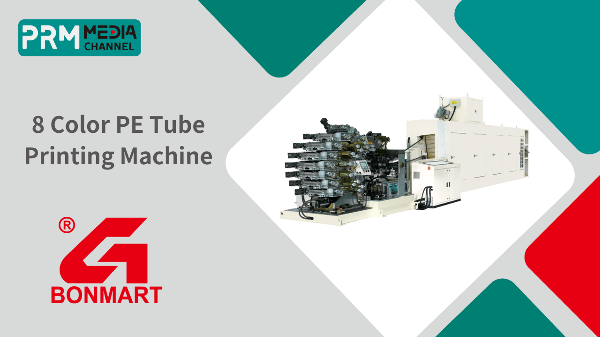

6 Cavities Automatic Injection Heading Machine | BONMART-

Double transferring rollers design. Stopless roller adjustment design. Plate wheel outer finetune mechanism Quick release ink rollers. Printing wheel clean system (200 mm dischargeable) Sleeve Printing Plate wheel pre-register mechanisim.