Five Layer Blown Film Line | Multilayer Blown Film Machine | Blown Film Extruder - Kung Hsing

/ Kung Hsing Main Products / K.S. manufacture Agricultural Blown Film Machine, Inflation making machine, Flat Yarn making machine, Plastic strapping band making machine, Plastic Recycling Machine, as well as special design for all extrusion system machineries and whole plant projects. #KUNGHSINGPLASTICMACHINERY #BLOWNFILMLINE #MULTILAYERBLOWNFILM

PIRANHA-45, Mini recycling machine | Lung Meng

PIRANHA-45, Mini recycling machine | Lung Meng

VDMA Interview | Insight into the European Plastics & Rubber Market

We are excited to share the interview with Mr. Florian Mikulasch from Germany, who is the Marketing Analyst of VDMA (German Mechanical Engineering Industry Association). Mr. Mikulasch shared a clear insight into the German and European Plastics & Rubber Market, the current problems due to the pandemic, the second lockdown in Germany, and the solutions that companies and associations bring to life to ease the effects of the pandemic. Welcome to add comments and ask your questions in the comment section. Also, let us know about the video interviews (Such as which market?) that you would like to see on PRM Media Channel.

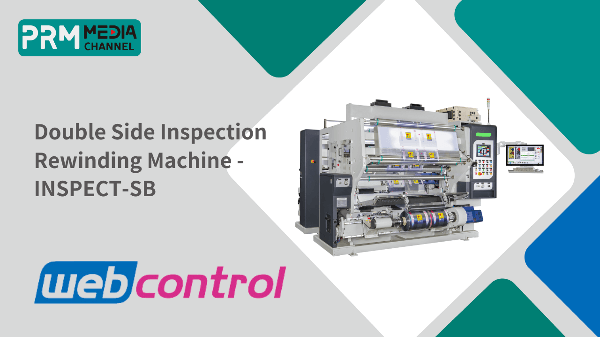

Inspection Rewinding Machine (INSPECT-SB) | WEBCONTROL

The double side inspection rewinding machine is designed print roll inspection. This model is able to inspect both sides of the material simultaneously to ensure the best quality in the minimum time.

Corona Treater | CHAANG HORNG-

.For non-conductive substrates .400~1600mm treat width available .One / Two side treatment .25mm segmented electrode finger .Φ 2.5” treatment roller

Solventless Lamination - Webcontrol

Solventless Lamination - Solventlless Laminator-LM-SF1300-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Solventless Lamination since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Solventless Lamination with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Solventless Lamination service ensure our worldwide customers must be satisfied.

Two Platen Injection Molding Machine 600TPIIR | CLF

Two Platen Injection Molding Machine 600TPIIR 3D animation from CLF. CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance. 【HIGHLIGHTS OF THE MACHINE】 Clamping Force 1800~4000 TONS Unique two-platen design for clamping mechanism exhibits exceptionally high-speed clamping feature. Clamping force, mold opening stroke, and distance between tie bars are easy to customize. Quick and accurate mold adjustment makes the machine suitable for small lot flexible production. Uniform force distribution on mold ensures the high accuracy of the product. Uniform tension force on tie bars for the dramatic increase of service life. Simplified construction with no wearing problem on toggle clamp. Rigid machine structure, minimum deformation, and consistent product accuracy.

Mold Cart | FORWELL

Mold Cart - Mold Cart System-Forwell Features -Fully automated die or mold changing - High precision die or mold placement - Increased safety and efficiency - Can serve multiple production lines at once - Multiple layout configurations System Introduction : Forwell's Die / Mold Cart System provides automatic die or mold changes for a range of different machines, such as plastic injection molding machines, plastic extrusion machines and press machines. This Die / Mold Cart system offers very fast, efficient and safe die and mold changes, using an advanced cart on rails system. Conventional die or mold changes can often take over an hour, but with the Die / Mold Cart System, die or mold changes are automatically completed in just a fraction of the time. Using this system, all procedures from die transfer and changing, to positioning and clamping is carried out by this system, resulting in extremely accurate die or mold changes. As the Die / Mold Cart System offers very precise die or mold changes, many operational issues can be avoided such as locking screws breaking when hand tightened, and incorrect mold alignment resulting in damage to the mold or production equipment. The Die / Mold Cart System also massively increases safety and efficiency, by allowing for automatic operations and making it feasible to perform many small batch production runs. Another great feature of this system is that it can be configured to specific user needs, different production facilities and serve multiple production lines at once.

Plastic Recycling Machine - Plastic Film Squeezing Machine | GENIUS

Plastic Recycling Machine -Genius- Plastic film squeezing machine Specializes in plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. The latest solutions for film washing line If you would like to produce the high quality and validity of pellets, you beware "Squeezing process must be prior to pelletizing process". After plastic recycled film materials are washed, the moisture is usually retain over 30%. Therefore, our superior design team specially developed a squeezer to meet customers’ needs. Through this machine, water and volume of the materials can be squeezed to increase the quality of the pellets and the efficiency of the extruders. Speed-changing gearbox We adopt a self-made gear box with high technology precision. Our single screw squeezer is equipped with a gearbox with two-speed derailleurs. According to characteristics of the materials you feed, you can choose which speed you want. You don’t need to buy another squeezer when you feed another kind of materials. It makes the whole washing line more efficient and saves much space. High Productivity Through our dedicated screw design, washed materials can be squeezed to dehydrate water of films or fluffy stuff. The recycled materials you feed are squeezed to become flakes or lumps . The moisture they contain will be lowered down to 1-3%. After being squeezed, these lumps or flakes with much lower moisture and higher density can be directly fed into pelletizing extruder. Its output can amount to 700~960kg/hr per hour and the degradation of the pellets will be highly decreased. Furthermore, you don’t need to increase heating rate. The quality and validity of the pellets and the efficiency of the extruder will be improved with the increased capacity. Always your best choice Our single screw squeezer can help you SAVE cost, SAVE energy, SAVE time, PROTECT environment, and INCREASE productivity as well as efficiency. It is definite your best choice! You NEVER miss it.

Business Tips of Choosing Plastic Recycling Machine | PRM What To Say EP17

Do you understand different kind of plastic recycling machines? Each type of plastic could be processed by certain type of machine. If you are still confused in choosing machines for your business, you must watch this video.

Rubber & Silicon lnjection Molding Machines | LONG CHANG

Long Chang is manufacturing the series of Rubber & Silicon injection Molding Machines, and Heated Compression Molding Machines etc. 【Machine Series】 Silicone Injection Molding Machine Rubber Injection Molding Machine Horizontal Automatic Rubber & Silicone Injection Molding Machine Single Body / Twin Body Vacuum Oil Hydraulic Compression Molding Machine Vacuum Rubber Oil Seal Hydraulic Compression Molding Machine Single Body / Twin Body Die-Moving & Ejection Compression Molding Machine Four Columns Type Oil Hydraulic Press EVA Foam Tire / Single Body Double Color Of Automatic Oil Hydraulic Compression Molding Machine 【Company Introduction】 Long Chang Mechanical lndustrial Co., Ltd. was established in 1971, under the leadership of president Huang Chin-Huo with the idea of "always be loyal to the obligation, give more than enough thought to operate the business" and demands "making the perfection more perfect" to be the target.

K Show 2022 Press Lunch Event | PRM x Kaigo

Are you excited to participate K Show 2022? You cannot miss the chance to watch this teaser! PRM will release the full videos or the following sharing session in September. Stay tuned! PRM was invited to join K Show 2022 Press Lunch organized by Kaigo Co., Ltd. Exhibitors who are participating in K Show 2022 were gathering in the event to be presented the show trending in this year, such as Circular Economy, Digitalization and Climate Protection. Sharing sessions was hold in the event which given by 1. Welcome Opening of Press Lunch - Kaigo Co., Ltd. Project Manager Mr. Richard Keim 2. K Show 2022 Trending - Kaigo Co., Ltd. Project Manager Mr. Alexander Keim 3. Make Plastic Green - Plastic Industry Development Center VP Ph.D Chiu Zen-Wen 4. Exhibition in Post-pandemic Era - Airtrade Express Ltd. Mr.Tommy Shih