Injection Molding Machine | CLF

Injection Molding Machine - Chuan Lih Fa Specializes in injection molding machine, CHUAN LIH FA MACHINERY WORKS CO., LTD. was founded in 1966, backed up with 40 years manufacturing injection molding machine, multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer experience. CLF Supply maximum injection machine machine all over the world. Precisely productive equipments and rigidly productive procedures have providing customers with satisfied multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer quality to help them getting most profit.

SIAF 2021 Guangzhou Exhibition Opens Door | PRM-TAIWAN

【 PRM-TAIWAN on SIAF Guangzhou 2021 Exhibition 】 Info: Great news for PRM-TAIWAN, Taiwanese Suppliers, and all the buyers who have put their trust in us! Despite COVID-19, we are glad to announce that thanks to our branch office in China, PRM has come back to the international exhibition ground to do what we do best - Provide professional services to international buyers! PRM-TAIWAN Plastics and Rubber B2B Platform: https://bit.ly/377P7Vv To keep updated about the latest news of the Plastics and Rubber Industry, please follow us on our Social Media Channels: PRM-TAIWAN Facebook: https://www.facebook.com/PRMTAIWAN PRM-TAIWAN LinkedIn page: https://www.linkedin.com/company/prm-taiwan/

5 Benefits of Flexo Printing Machines | PRM What to Say EP11

There are several types of printing techniques available for the plastic packaging industry. Such as flexo printing, offset printing, and screen printing. Although flexo printing is not a new technology, it is the most common method for packaging printing. Then let’s take a glimpse of the video to understand what flexo printing is and what makes it most preferable. Flexographic printing is a technique that uses a flexible printing plate. The plates are wrapped around cylinders on a web press. The inked plates have a raised image and rotate at high speeds to transfer the ink through small holes from the anilox roll to the substrate, which is the printed surface. So, what makes flexo printing the most common method? You will find 5 reasons why in the video.

TPE, TPR, TPU Materials Explained | PRM What to Say EP12

In this episode, we will open a special page for TPU and TPE, TPR materials. Because there are several common confusions about them. Then, let’s understand the differences and fields of application of those innovative materials together. 【TPE/TPR】 Both TPE(Thermoplastic Elastomer) and TPR(Thermoplastic Rubber) belong to the family of Thermoplastic Elastomers, and there isn’t a defined industry standard to distinguish them. But, it is certain that TPE is made from SEBS, while TPR is made from SBS block copolymers. [TPE/TPR Applications] TPE/TPRs are great for anywhere that flexibility, comfort, or cost savings are needed. They are a top choice for medical applications like surgical and dental tubing and also tubing used in the food/beverage industry. 【TPU】 TPU(Thermoplastic polyurethane ) is a soft polyether type polyurethane that is available in a range of hardness grades, which gives a diverse application range to TPU. There are two main types based on soft segment chemistry: Polyester-based TPUs, and Polyether-based TPUs. [TPU Applications] With their resistance properties, TPU is superior for use anywhere that ozone, extreme temperatures, and high levels of abrasion are a concern. In addition to medical uses, TPU is also a popular material for sporting goods, tubing, wire, protective coatings, and more. All those materials above are alternatives for natural rubber and are easy to manufacture. Moreover, those materials can be 100% recycled.

Solventless Laminating Machine (LM SF1300T) | WEBCONTROL

Webcontrol develops innovative solventless laminators with driven coating system and automatic turret unwind & rewind for high efficiency, consistent tension & minimum waste during roll changes.

2024 Expo Plasticos Guadalajara | HAO YU PRECISION MACHINERY INDUSTRY CO., LTD.

Join us as we interview Hao Yu Precision Machinery Industry Co., Ltd. at ExpoPlasticos 2024! We shine a spotlight on Hao Yu’s expertise in manufacturing PP/HDPE woven bag-making machines. With 26 years of local experience in Mexico, Hao Yu’s unique advantage lies in its direct communication with customers, ensuring tailored solutions to meet their needs. Their commitment to sustainability, combined with a strong willingness to engage directly with local buyers, enables them to deliver highly customized solutions that meet diverse needs.

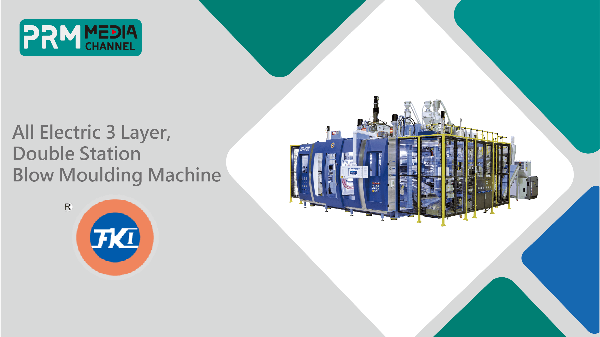

All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

Product (Jerry Can) 15lt/20lt Product Weight (N.W) 550g/680g Product Rate 270bph Avg. Power Consumption 67kW/102A Service Circuit Breaker 211kW/320A Machine Dimensions (LxWxH) 10x8x4.4m More information, please visit us at: www.fki.com [email protected]

TaipeiPLAS 2022 Live | PRM

The self-media era is coming! The plastics & rubber industry not only allows specific people or professionals to learn about this area. Throughout PRM's interview videos, we convey general information from plastics & rubber industry, environmental issues and social enterprise responsibility topics. ⏰ 10/1(Sat.) 15:00 (GMT+8) 【PRM exhibition insight interview】 We'll introduce the innovative machinery and techniques by interviewing exhibitors at TaipeiPlas 2022. To those who cannot attend the exhibition and overseas buyers, you can watch our on-site interviewing video to obtain the latest information.

Bag on Roll Making Machine-Draw tape Garbage Bag|Plas Alliance Ltd.

Are you looking for plastics and rubber suppliers for machinery, molds, raw materials, auxiliaries, and so on? Here is PRM-TAIWAN B2B Platform only one click away. Visit our website now and search for your Taiwanese suppliers. Learn More : • Bag on Roll Making Machine|Draw tape G... ------------------------------------ Draw tape garbage bags are advanced type of garbage bags which has strong tensile strength and puncture resistance, and controlled elongation for volume. The draw tape can be pulled and knotted for secure closure. Bag on roll are good and compact for transportation and end use for household consumers. - Bag making application - Draw tape garbage bag on roll - Folded draw tape garbage bag

Injection Molding Solution | Plastic Injection Molding Machine Manufacturer | CLF

Chuan Lih Fa Injection Molding Machine at steady development of injection molding fields. With strict standards of the quality and the clamping force of the machines, combining high-tech European and Japanese microcomputer controllers, our electric injection molding machine adopts German Siemens controlling system as well as servo motors. The innovative structural design makes Chuan Lih Fa a leader in this industry.

Twin Line Bottom Wire Impulse Sealing and Flying Knife Cutting Machine MGA-01-1000D | MING JILEE

Twin lines Bottom Bag impulse sealing and flying knife cutting machine, MGA-01-1000D

Greenhouse Gas Emissions | PRM What To Say EP14

Climate Change, Extreme Weather, Greenhouse Gas Emissions and Plastic Reduction, those topics have been discussed for many years. What should we do to help the environment better? Starting not to use the air-conditioner, not to eat meats that might decrease a little. Moreover, we could take action to use reusable materials, to reduce the frequency of ordering food delivery and use eco-friendly products. In this episode, we are conveying messages about the global warning to everyone that might lead you to think “What should we do for the Earth?”

rPET Bottle for Household Packaging Solution | ChumPower

Over 40 years of history, CHUMPOWER is the largest PET blow molding machine manufacturer in Taiwan, and the CHUMPOWER PET blow molding machines made in Taiwan are in stable operation in more than 115 countries. 【Product Appliance】 Beverages Water Edible Oil Daily-used Cosmetics 【Product Range】 One Stage Injection Blowing Machine Injection and Bottle Molding Manufacturing Stretch Blow Molding Machinery Sales / Turnkey Solution TS Series Models for Lower Production Output (Suggest to new market players) Linear PET Blow Molding Machine (Suggest to buyers who is looking for higher output) 【SS10-rPET Single-stage PET Bottle Blowing Machine】 Hybrid hydraulic system with an optimized clamping mechanism to ensure Energy Efficiency Barrier screw with venting capability can effectively lower the energy required for drying Adopt 4 station design Non-contact feature Reach the trending topics of ESG, Carbon Neutrality, and Net-Zero Emission

GOLD GREAT GOOD MACHINERY | PRM Media Channel Interviews at TAIPEI PACK 2020

At the recent packaging machinery exhibition, TAIPEI PACK 2020, we have interviewed Rita from GOLD GREAT GOOD MACHINERY. Rita shared her opinions and observations about the packaging industry, their implementations to ease the effects of the pandemic on the business, what kind of changes they made to sustain customer service efficiently for the PRM Media Channel audience. Moreover, Rita also introduces the machinery portfolio they have in the video. Let's take a look and share your opinions with us!~

【Turnkey】Biodegradable / Compostable Straw Making & Packing Machine | JUMBO STEEL

Jumbo Steel has more than 30 years of experience in manufacturing straw making machines and straw packing machines. Moreover, Jumbo Steel is providing turnkey solutions for your business according to your needs. 【Product Lines】

Triangle Folding Machine, 1 Color Rotogravure Printing | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000 from MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

The Best Choice of Bag Making Machines | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Product Lines】 T-shirt Bag On Roll Making Machine Bag On Roll Making Machine T-shirt Bag Making Machine Garbage Bag & Industrial Bag Making Machine T-shirt & Bottom Sealing Bag Making Machine Side Sealing Bag Making Machine Air Cushion Bag Making Machine Stretch Rewinder Glove Making Machine 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

Shrink Sleeve Conversion Seaming Machine - K5 Plus | WEBCONTROL

Machine Specification - WEBCONTROL Seaming Machine K5 Plus: -Machine Speed: 500 m/min -Width: 350 mm -Material Width: 720 mm -Unwind Diameter: 600 mm (Option 800 mm) -Rewind Diameter: 600 mm -Minimum Lay Flat Width: 40 mm with 18 mm option -Core Diameter: 3" (76 mm) -Lay Flat Tolerence: 0.25 mm The K5 PLUS combines all the advantages of the new PLUS technology with non-stop operation. The new PLUS series is the most advanced seamer in the industry. WEBCONTROL has once again innovated by launching the third generation of seamers which eliminates the forming tool. This new patented design makes the K5 PLUS the most operator friendly machine available, facilitating operator training with the most automated machine on the market. The K5 PLUS has 3 tension zones, which allows for a dedicated tension zone in the forming section for better layflat control. The unwind tension zone is now free to add innovations like laser integration for t-perforation or pin hole perforation while the film is flat. The K5 PLUS offers a long list of advantages that solve the issues that come with the previous generation of machines that use forming tools. This new machine promises to revolutionize the way shrink sleeves are converted. Make sure you see it before making any decisions.

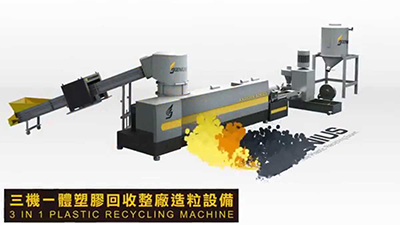

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS Specializes in waste plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in waste plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our waste plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. Product Feature: -Drive-train: High torque gearbox made with precision grinding. Low noise, steady and smooth operation. -Low power consumption, high output. Dedicated screw and barrel design: According to the characteristics of recycle materials, dedicated screw is designed to completely impurities such as water and bad air; the screw also has a variety of advantages, for examples, good mixing, good dispersion, high output, and others. Die head pelletizing eliminates the labor cost on batter brace. No water tank. Consumes less space. Extruder is equipped with pressure sensors. When there is excessive pressure, warning light or buzzer send notification for replacing filter screen. No need to shut down the machine when replacing the filter screen. Single extruder suitable for cleaner material pellets such as injection leftovers, edge trim.

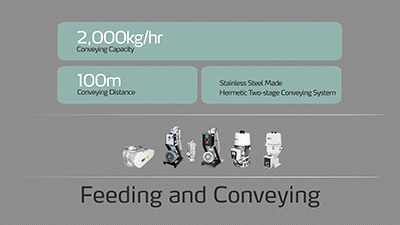

Plastic Dryer, Hopper Loader, Gravimatric Blender | SHINI

Plastic Dryer, Hopper Loader, Gravimatric Blender - Products Overview -Shini Specializes in plastic dryer and hopper dryer. SHINI PLASTICS TECHNOLOGIES, INC. products including hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chillers, sprue picker, side entry robot,gantry robot and more. The Shini Group, Originate from Taipei, Taiwan since 1969. Five manufacturing bases and one corporate technologies center around the world. World class manufacturer of plastics auxiliary equipment. For 41 years, Shini people adhered to the management principle of Focusing on Particular Business, Pursuing to be the World Leader which created new era and achieved many progresses. Shini Group has now become a world-class manufacture of plastic dryer, hopper dryer, hopper loader, gravimatric blender, gravimetric blender, volumatric doser, volumetric doser, mould temperature controller, granulator, material handling system, injection molding robot, hot runner, water chiller, sprue picker, side entry robot, gantry robot.

Sensing & Polymer Test Equipment at K 2022 | Dynisco

We are glad to have an interview with Bill Desrosiers, Vice President of Dynisco, since our last interview at K 2019. The industry has been changed a lot due to COVID said by Mr. Desrosiers. Moreover, we had a discussion of how Dynisco implemented trending topics at K 2022, such as Circular Economy, Digitalization and Environment Protection, and applied these concepts in Dynisco products.

2023 VietnamPlas Interview | Chan Chao

It's our great honor to interview Tracy from Chan Chao. Tracy also introduced their services in holding worldwide exhibitions.

All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

All Electric 3 Layer, Double Station Blow Moulding Machine for plastic bottle making Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system. Product (Jerry Can) 15lt/20lt Product Weight (N.W) 550g/680g Product Rate 270bph Avg. Power Consumption 67kW/102A Service Circuit Breaker 211kW/320A Machine Dimensions (LxWxH) 10x8x4.4m More information, please visit us at: www.fki.com

Water Transfer Printing Dipping Machine | YHT

Since 1990, YHT has been a manufacturer for Printing High Definition Water Transfer Films, leading the way with short new pattern development time, quick lead time to turn around on film printing orders, and providing many solutions to qualify customers demands. We have been supplying films to many famous brand companies all around the world, and these work experiences have made us irreplaceable on Water Transfer Printing (WTP) business. We not only do printing films, but we also make relevant dipping and wash machines to supply a completed chain of product. 【Advantages of our Water Transfer Printing】 Color and design of the pattern through water pressure Decoration is possible for many sizes, shapes, and flexible products 【Applied Products】 Ski goggles, EVA shoes, electric switches, rifle scope, firearm, crossbows, dog leashes, home appliances, car panels, and steering wheels are all in the scope of WTP process.

2024 CHINAPLAS Interview | CHINAPLAS

We are here with Ms. Ada from the CHINAPLAS. She also shared very useful information about the forthcoming CHINAPLAS 2024 including the focus of the exhibition.

Shade Net Knitting Machine - EL system | FUNG CHANG

Shade Net Knitting Machine with EL system from Fung Chang Industrial Co., LTD. Slitting and Extension Machine, Raschel Knitting Machine, Knitting Unit, Winding Unit, HMI Control System, EL System. INQUIRE @ https://www.prm-taiwan.com/com/fung-chang.html?utm_source=youtube.com&utm_medium=social&utm_campaign=YouTube-Video&utm_term=pyfUJbABx3E&utm_content=fungchang

High Speed 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI

High Speed Fully Automatic 2 Lines Coreless Bag on Roll Trash Bag Making Machine | CHAO WEI, TAIWAN [DESCRIPTION of the Machine] ⚡️Special for two lines perforating coreless bottom and star sealing bags on roll. ⚡️In-line triangle folding device for star sealing bags. ⚡️E.P.C. (Edge Position Control) for the film at correct position. ⚡️Japan made servo motors & servo drivers control bag length precisely and high speed production, reducing electric consumption. ⚡️Bag length & production speed can be changed easily from touch screen. ⚡️German made photocell-SICK for accurate printing mark. ⚡️Automatic lift up reel unwinder with air shaft, reducing the number of employees. ⚡️Automatic tension control with AC motor and inverter system for jumbo diameter film roll. ⚡️Two lines automatic roll changing system.

FSL-TR series Turret Rewind Slitting Machine | HCI

HCI’s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

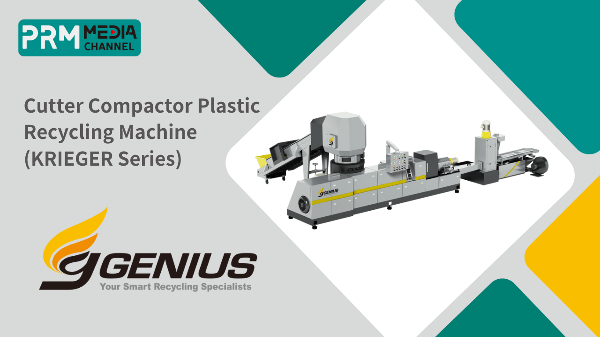

Cutter Compactor Plastic Recycling Machine (KRIEGER Series) | GENIUS

The KRIEGER series cutter compactor plastic recycling machine integrates crushing, extruding and pelletizing in one machine. A proprietary designed cutter compactor can compact the density of fluffy plastic film to flakes. It helps to increase the efficiency of extruder. After compactor, the materials are extruded to Genius patented universal joint pelletizing system. The universal joint pelletizing system can automatically adjust the distance when cutting the polymer to pellets. Significantly reduces manual adjustment error rates. After cooling, these pellets are sent to centrifugal dryer to remove moisture. A vibrator at next step removes powders or oversized pellets. Finally, recycled pellets can be reused in different fields, for example, blow film or injection molding industries. / Key Features of Cutter Compactor Plastic Recycling Machine / Energy cost saves up to 20% Only 1~2 operators are needed to operate the pp recycling machine. High-speed rotation operation makes the fluffy material compact. Simultaneous material dewatering. Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The temperature control is convenient, and the temperature of the crushing barrel is controlled in a stable manner. Provide customized recycling, sorting, feeding, degassing, filtering, granulating to storage and packaging systems.

Injection Molding Process & Benefits | PRM What to Say EP10

Have you ever wondered how daily used plastic materials are made? Plastic materials are a part of our everyday life. Many of them are made by Plastic Injection Molding process. Starting from toothbrushes, cups, plates, automobile parts, hand tools, electric and electronic hardwares, and so on. So, why is plastic injection molding commonly used for plastic materials manufacturing? We answered these questions and listed 6 benefits of the plastic injection molding process for you. Come take a look at the video to discover more about the plastic injection molding machines and production process.

WEI MENG | WMD Onion Bag Making Machine

Our Double Needle Bar Raschel Machine is the perfect solution for businesses that need to produce high-quality, high-speed packing sacks. With a working width of 170 inches and gauges of 2 - 6 needles per inch, this machine can produce a variety of nets for different purposes. It is also ideal for producing onion bag machines, special wide nets, and double-layered nets. This machine is equipped with a high-speed warp supply system that ensures that your nets are produced quickly and efficiently. It also has a number of features that make it easy to use, including a user-friendly control panel and an automatic yarn tensioning system. If you are looking for a high-quality, high-speed Double Needle Bar Raschel Machine, then our machine is the perfect choice for you. Contact us today to learn more about our machines and how they can help your business. Double Needle Bar Raschel Machine is specially designed for onion bag and double layer nets making. This machine is applicable Yarn is HDPE flat yarn and monofilaments. Standard gauges machine 2 - 6 needle per inch, Maximum performance of the machine can up to 600rpm.

2024 CHINAPLAS Interview | ANIPAC

It’s our great honor to interview Mr. Aldimir Torres Arenas from ANIPAC He shared his insight for the China and Mexico market. Check our video for more information!

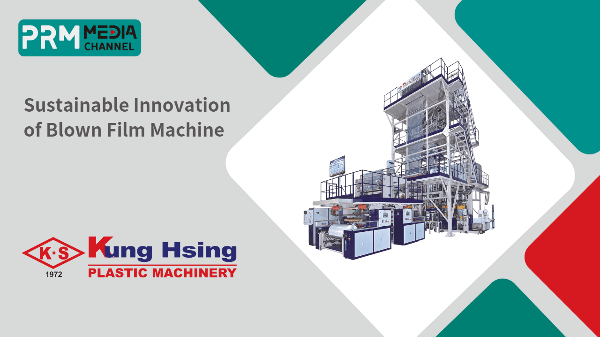

Sustainable Innovation of Blown Film Machine | KUNG HSING-

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy.

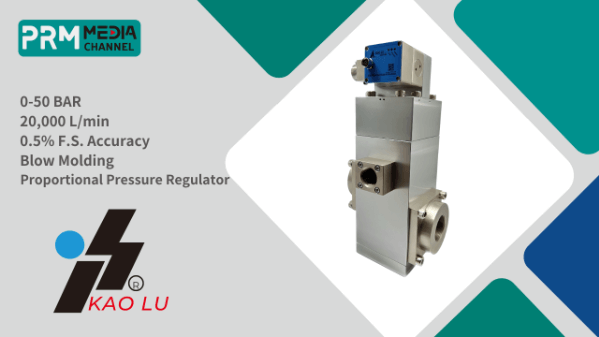

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | KaoLu

Product Description The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation. Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design. For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc. Applications for Electronic Pressure Regulators Spraying/ Painting Air Blowing Leak Testing Filling Pressure Artificial Heart Laser Cutting FAQ session – Proportional Electronic/Digital Pressure Regulators What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge? They are the same products with different names. Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc. Is the pressure regulator resistant to dirt? No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm. Any restriction on mounting orientation? Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag. Knowledge Base How Does a Proportional Pressure Regulator Work? A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control. Uses of Regulators Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications. The Working Process: Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static. When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal. Please check our video on: GennDih Enterprise. Co. Ltd

Crystallized Hopper Dryer(CHD) | YANN BANG

Our PET / PLA Crystallizer is a closed-loop heating system continuously to re-crystallize PET amorphous resin and covert it into crystalline state. FEATURES The crystallized hopper dryer is designed with a unique mixer inside the stainless insulated hopper.The unique mixer stirs the resin simultaneously while the unit is drying.To crystallize,it increases the I.V. value and speeds up the crystallization. To Dry the mixer dries evenly and shortens the drying time. YANN BANG Crystallized Hopper Dryer is the best choice for PET users. 1. SAVE COST. With YANN BANG's patented drying technology,the crystallized hopper dryer mixes the resin evenly while drying and shortens the drying time. 2. PREVENT BRIDGE MAKING. When drying oily,sticky,abnormal shaped resin,it is easy to have the bridge making.To use the crystallized hopper dryer can prevent the bridge making effectively. 3. NUMEROUS MIXERS AVAILABLE. Different kinds of unique mixers to suit for your special needs.

GENIUS MACHINERY: Innovation & Current Situation in the Plastic Recycling Industry

We are very excited to announce that we have published a Live stream with GENIUS MACHINERY CO., LTD. on October 16th, 21:00 (GMT +8) . Mr. Peter Tsai, General Manager of the company will be our guest that we are expected to have the latest insight from the industry. It was a great opportunity to understand more about one of the main players in the Recycling industry in Taiwan. We covered different topics such as company introduction but also the general introduction of their products, including their Plastic recycling machines, plastic washing plants, pelletizing systems, drying machines of plastic washing lines, and also their shredders and crushers. Within their items will also explain their KRIEGER-Series that are cutter compactor recycling machines, RECO-series recycling machines with side force feeder, and DW-series squeeze dryer. During this 2020 year, one of the main highlights has been the up and down and uncertainty for the Plastics industry, Mr. Peter will explain to us all the different ways they have been doing to overcome a variety of challenges, such as many methods to maintain close interaction with the customers.

Haitian Mexico Interview Part 2 | Solutions for Pandemic and Future Outlook

At the beginning of the month, we had a video conference with one of the greatest Injection Molding Machine Industry from Mexico, Haitian Mexico! In Part 2 of the video conference the Deputy General Manager of HAITIAN MEXICO, Jose Antonio Barroso, talked about the challenges they are having due to the pandemic, their solutions to overcome those challenges, and the current situation of COVID-19 in Mexico.

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU-

THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE MODEL: KMTL-55-65-55 E3 Screw/Barrel: 55-65-55 mm Roller width: 1600mm Film width: 1400mm Film thickness: 30mic

2024 CHINAPLAS Interview | ETERLONG

We are here with Melody from Eterlong Co., Ltd at the CHINAPLAS. ETERLONG is known for high-quality products, such as blown film machines, extrusion die and extruder filters, and their post-sale service. We gained information about how ETERLONG applies digitalization to their equipment.

Bangladesh Culture and Tips on Operating Market | PRM What To Say EP18

Bangladesh has a rich, diverse culture. Its deeply rooted heritage is thoroughly reflected in its architecture, dance, literature, music, painting and clothing. For this episode, we’re going to talk about Bangladesh culture and tips on the operating market. Let PRM Cicilia share her insight and observation about Bangladesh Market!

Automatic Log Roll Cutting Machine|Four-Shaft Log Roll Cutter | Yicheen

Automatic Log Roll Cutting Machine can be applied to cut rolls of various tape materials, such as double-sided tape, electrical tape, masking tape, construction tape, etc.. More product info: ???? https://bit.ly/3q8uLWw / Automatic Log Roll Cutting Machine Features / Cutting running is driven by AC motor with inverter control. Fast and stable to speed up & down. PLC control system Auto change cut size setting in the same shaft. Precise and smooth positioning. Multi-speed cutting rolls to improve operating efficiency and maintain high quality. The blade has different angle changes according to different materials, reducing the number of tool changes. / Advantages of Yicheen / Leading the industry in the research and development of the Die-Cutting Machine". In addition to the continuous improvement of technology, it has also developed a variety of Printing Machines, Laminating Machines, Cutting Machines, Sheet Cutting, Slitting Machines, and other equipment to provide complete plastics Processing equipment solutions. / links of Yicheen / Contact us: https://bit.ly/3q8KLaK Subscribe us: https://bit.ly/3wGjjU3 Product Info: https://bit.ly/3tU2QdK

CHINAPLAS 2025 | Innovation and Collaboration for Sustainability

Experience the future of plastics at #CHINAPLAS2025! Shenzhen World Exhibition & Convention Center (Bao'an), Shenzhen, PR China 15-18 April, 2025 Let's embark together on this journey of innovation, collaboration, and sustainability! See you there #PlasticsInnovation #CHINAPLAS

Rubber & Silicon lnjection Molding Machines | LONG CHANG

Long Chang is manufacturing the series of Rubber & Silicon injection Molding Machines, and Heated Compression Molding Machines etc. 【Machine Series】 Silicone Injection Molding Machine Rubber Injection Molding Machine Horizontal Automatic Rubber & Silicone Injection Molding Machine Single Body / Twin Body Vacuum Oil Hydraulic Compression Molding Machine Vacuum Rubber Oil Seal Hydraulic Compression Molding Machine Single Body / Twin Body Die-Moving & Ejection Compression Molding Machine Four Columns Type Oil Hydraulic Press EVA Foam Tire / Single Body Double Color Of Automatic Oil Hydraulic Compression Molding Machine 【Company Introduction】 Long Chang Mechanical lndustrial Co., Ltd. was established in 1971, under the leadership of president Huang Chin-Huo with the idea of "always be loyal to the obligation, give more than enough thought to operate the business" and demands "making the perfection more perfect" to be the target.

Five Layer Blown Film Line | Multilayer Blown Film Machine | Blown Film Extruder - Kung Hsing

/ Kung Hsing Main Products / K.S. manufacture Agricultural Blown Film Machine, Inflation making machine, Flat Yarn making machine, Plastic strapping band making machine, Plastic Recycling Machine, as well as special design for all extrusion system machineries and whole plant projects. #KUNGHSINGPLASTICMACHINERY #BLOWNFILMLINE #MULTILAYERBLOWNFILM

Slitting Machine (HS-Compact) | WEBCONTROL

The SLIT-HSC series slitter is new compact type to save the working space. From the unwind side, the web is guided middle to the main machine, easy access to the slitting section and eliminates dust collection/hazarded steps. The slitter comes standard with razor cutters and groove roller configuration. A shear cutter system is offered as option for paper and other pressure sensitive materials. The machine uses three AC Vector Drives and has automatic tension on unwind and rewind controlled through easy-to-use PLC & MNI touch screen. Friction rings are used on rewind shafts to ensure the production of quality slit rolls when the film thickness varies.

Taiwan Injection Molding Machine | CLF

Taiwan Injection Molding Machine - Chuan Lih Fa Products: plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle. Contact Information: https://www.clf.com.tw/en/contact.html