Plastic Injection Molding Innovations and Green Solutions | KING'S SOLUTION

Livestream time: November 20th at 19: 00 (GMT +8, Taipei) The Livestream that PRM Media Channel held with KING'S SOLUTION CORP. with the title of Plastic Injection Molding Innovations and Green Solutions brings you new insight into the injection molding machine industry. Remember to direct your questions in the live chat section, KING'S SOLUTION and PRM Media Channel will be replying to your questions. What are the challenges, trends, and innovations in the injection molding industry? How to sustain after-sales services during post-pandemic? What advantages LPM (Low-Pressure Molding) brings to the manufacturers compared to Epoxy Injection Molding? Do you also have similar questions like that or would like to learn more? Then we welcome you to watch the Livestream video on November 20th at 19: 00 (GMT +8, Taipei) 【VIDEO OUTLINE】 00:00 Opening 00:59 KING'S SOLUTION CORPORATION 02:00 "Green Solution, Machine Soulmate" Slogan 03:04 Why to customize the machines? 05:00 Customized Machine Series 06:00 Market Challenges and Successful Cases 10:38 5 Gallon PET Preform Injection Molding Solutions 12:35 Advantages of KING’S in 5 Gallon PET Preforms 16:16 Trends in Injection Molding Market 18:40 LPM Application Examples 23:00 LPM Method vs Epoxy Method 26:00 After Sales Services and Customer Relations 28:55 Message to Current and Potential Customers Know PRM Media Channel more on: PRM Media Channel Website: https://bit.ly/3uqdubs PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

Accumulator Blow Moulding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. Detail Specifications : The Abl Series Blow Moulding Machines Are Particularly For Producing The Jerry Can/Drum Tank/Large Article Produtions.It Can Be Combined With Some Accessory Equipments To Increase The Efficiency And Expand The Functions, Such As: After Cooling Unit/Auto Deflashing Unit. The Die Head Can Stock The Melting Resin And Purge The Material For Blowing Formed It Designed With Two Heart Flow Chnnels.Can Make Welding Line-Free To Increase The Strength Of Production. The Tie Bar-Less Clamping Unit Is Consist Of Stiffness Structure Frame And Guiding Devices.Make Sure Deflection-Free Advantage. Also Devise With Precision Rack GgearsO of Bboth Side.Make Synchronize Moving Of Plates. The Blowpin Unit Is Designed For Production Calibrating. That Will Be Suited For Different Demand Of Customer. Accumulator Die Head Blow Moulding Machine. GEFRAN CONTROL SYSTEM -PID Temperature Control System (With High/Low Alarm) -Motor PID Feedback Control Function -300 Points Parison Control -PLC Ladder Program Edlitor -Presscription Record Memory Accumulator Die Head Blow Moulding Machine AUTO-DEFLASHING UNIT This Unit Can Be Excuted Top/Bottom/Handle Deflashing Function By Hydraulic And Pneumatic. And Then Used With Suction Device To Take Out And Turn Over The Production.

Fibrillated Tape Extrusion Line (JC-FYB) | PLASCO

PLASCO's JC-FYB Series of extrusion lines are designed to produce either standard or heavy-duty fibrillated tape for technical end-use applications, such as baler twine, insulated cable filler, carpet backing, synthetic grass, and more! 【Machine Spec】 Applicable Materials: PP / HDPE Screw Diameter (mm): 85 / 100 / 110 Denier (D): 3000-25000 / 3000-30000 / 3000-35000 Working Width (mm): 800 / 1000 / 1200 Extrusion Capacity (kg/hr): 120 / 200 /250 【Application】 Rope Cable filler Baler twine 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Zipper Bag Making Machine | WORLD STEEL

World Steel-Zipper Bag Making Machine

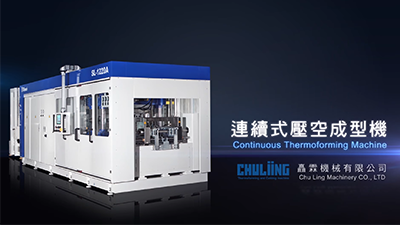

Thermoforming Machine | CHULIING

Thermoforming Machine-Continuous Thermoforming Machine Chuliing Machinery Co., Ltd was established in 1985 and is now an expert in manufacturing Thermoforming Machine. Our products are sold worldwide and we are well-known die cutting machine manufacturer. Chuliing Machinery has a commitment to technological innovation so as to benefit his customers and agents from all aspects. We also dedicate ourselves to develop automatic equipment and to train our employees to further enhance our Thermoforming Machine product quality.

Surface Modeling 3D Printing | time lapse | Everplast

Surface Modeling 3D Printing | time lapse | Everplast ①The EM3-3505-CMT is an industrial pellet 3D printer manufactured by Everplast from Taiwan. ②This 3D printer is able to utilize compound cement raw material to build products or samples. ③The standard formulation database and material bank are provided along with the 3D printer.

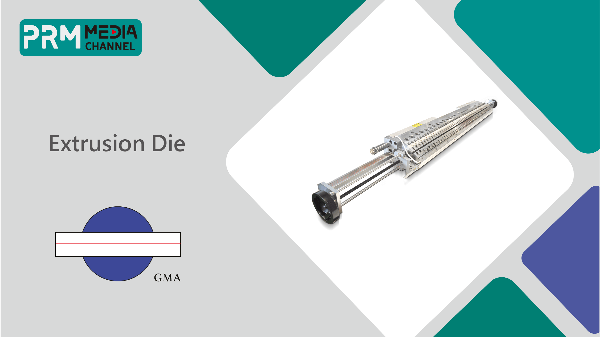

Extrusion die and peripherals manufacturer | GMA

Founded in 1989, the GMA Machinery Enterprise Co., Ltd. (GMA), an R&D team composed of senior design engineers and technicians with decade’s strong experience in sheet and film extrusion equipment and auxiliary parts, has been devoted to providing custom products based on customer requirements. With 30 years of continuous efforts, it is the one of the best manufacturer in the world. Based on comprehensive processing equipment, GMA is able to exercise strict quality control throughout the whole in-house process from product design, manufacturing, assembling and inspection which, in turn, has earned customers’ continuous recognition and praise.

Medical spiral tube extrusion machine line (double output ) | Everplast

Medical spiral tube extrusion machine line (double output ) The medical tube, made by food-grade materials, with the advantage of high transparency, good elasticity, good fluidity and corrosion resistance, suitable for medical, pharmaceutical and food production of gas and liquid delivery pipes, etc. -Contact Info: Twitter: / everplast Facebook: https://reurl.cc/r1LZb Web: https://www.everplast.com.tw/ Tel: +886-2-2289-7271 / +886-6-201-4846 Fax: +886-2-2289-7282 / +886-6-201-4290 Email: [email protected]

Liquid, Solid and Granule Food Packaging Machine Solutions | SAN TUNG Interview

At the last version of the TAIPEI PACK exhibition, PRM Media Channel had an interview with SAN TUNG MACHINERY. We invite you to take a look at the food packaging machine solutions and industry observation of SAN TUNG. In the video, you will find the on-site machine introduction of - Liquid Food Packaging Machine Solutions - Solid Food Packaging Machine Solutions - Granule Food Packaging Machine Solutions by the demonstration of Mr. Yao & Ms. Cathy. Moreover, Ms. Cathy is also sharing her insights into the current situations in the packaging industry, and her expectations of future cooperation with their clients.

PP Strapping Band Extrusion Line (JC-SPP) | PLASCO

PLASCO's JC-SPP Series of extrusion lines are designed to produce PP strapping bands, which are commonly used for light- and medium-duty applications, such as for securing newspapers and magazines, carton boxes, and pallet freight shipments. 【Machine Spec】 Applicable Material: PP Screw Diameter (mm): 90 / 100 / 120 Strap Width (mm): 5-19 / 12-19 Extrusion Capacity (kg/hr): 180 / 250 / 380 Straps Produced: 4-2 / 8-4 / 8-6 【Application】 Newspaper strap Carton box strap 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Leading European PA Supplier DOMO Accelerates Strategic Development in Asia Pacific (English & Chinese Interview)

Domo Chemicals is a leading producer of high-quality engineering materials and versatile plastics for industrial and consumer applications in a diverse range of markets, including the automotive, food, medical, pharmaceutical, chemicals and electronics industries. The company offers a complete portfolio of integrated nylon 6 and Nylon 66 products, including intermediates, resins, engineering plastics and packaging filmand distribution of petrochemical products. Headquartered in Germany, the family-owned company leverages advanced technology and consumer insights to deliver sustainable & innovative solutions.