Five-Layer Extruder & Cutting Machine | BONMART

【Machine Features】 Plastic material has its own characters. In co-extrusion system. BONMART uses and combines several kinds of materials, therefore, the characters of single layer tube can't compete with the complex characters of co-extrusion tube. Glossy surface (using: EVOH / RESIN / PE)Extensive color combination (using: PE + PEARL / PE + PIGMENT)Excellent barrier property (using: PE / TIE RESIN / EVOH / TIE RESIN / PE) Scratch and dust free (using: LDPE / LDPE / LLDPE)Co-extrusion is used on pesticide container, toothpaste, side window, multicolor, long preservative cosmetic... etc. 【Company Intro】 BONMART offers complete-line including technology transfer, cost analysis, layout, installation, test run, training and satisfactory after sale services. Using our Squeezable PE Tube equipment is the best choice of good investment, Welcome to contact us for more details any time.

Shade Net Knitting Machine - EL system | FUNG CHANG

Shade Net Knitting Machine with EL system from Fung Chang Industrial Co., LTD. Slitting and Extension Machine, Raschel Knitting Machine, Knitting Unit, Winding Unit, HMI Control System, EL System. INQUIRE @ https://www.prm-taiwan.com/com/fung-chang.html?utm_source=youtube.com&utm_medium=social&utm_campaign=YouTube-Video&utm_term=pyfUJbABx3E&utm_content=fungchang

PP Flat Yarn Extrusion Line & Raffia Tape Stretching Line Plant|HAO YU

The extrusion line has maximum PP melting output. Capacity is 160 ~ 520 kg/h and the unit is equipped with a screen filter changer and rotary blade slitting system. The machine has less down time and prevents production loss. The pressure rollers of the take-off unit are pneumatically controlled, and have synchronized control electronic system. Available to meet special requirements. 【Company Introduction】 Hao Yu Precision Machinery Industry Co., Ltd. is a leading manufacturing of PP and PE woven bag machinery and whole-plant equipment. Since its establishment 1980, HAO YU has been dedicated to the research and development of high performance machinery.

PP Woven Automatic Cutting-Sewing (Conversion) Line (CS-series) | BOTHEVEN

*Accurate bag length control by Servo Motor *Gripper bag transfer system, most advanced design *Maximum output 50 bag/min *Optional devise such as Gusset, Powder Brake, Easy Open function, Punch system, Liner Insert, Bottom Wrap *Union Special Sewing machine customized model available For more information, visit http://www.botheven.com.tw

2024 InterPlas Thailand Interview | Chang Horing

We had the pleasure of interviewing Chang Horing Rubber Group, a leader in the rubber compound industry with over 20 years of experience, at Thailand InterPlas 2024. In this engaging conversation, they shared their expertise in developing and customizing rubber compounds for various industries, including automotive, chemical, heavy-duty, food, and water sectors. Chang Horing's dedication to quality and precision is evident in their state-of-the-art facilities, equipped with advanced systems and instruments to ensure high-quality consistency. They also discussed their future plans and initiatives related to Environmental, Social, and Governance (ESG) practices, highlighting their commitment to sustainability and innovation. We thank Chang Horing Rubber Group for sharing their valuable information and look forward to seeing their continued success in the industry.

Swop’s Evolution: Ms. Ku on Meeting the Growing Demands of Packaging

Join us as we talk to Ms. Ku, the General Manager of swop, about the exhibition’s remarkable journey and how it continues to adapt to the ever-changing needs of the packaging industry. Ms. Ku shares how swop has transitioned from a biennial event to an annual gathering, enabling it to better meet the growing demands of the packaging industry. She also highlights the valuable conferences and discussions happening during the exhibition, providing insights into the latest trends and innovations shaping the sector. As the conversation concludes, Ms. Ku shares her personal goals and aspirations for this year’s swop, giving us a glimpse into the vision behind this impactful event. Don’t miss this insightful dialogue with a key leader driving change in the packaging industry!

Sheet Cutting Machine | YICHEEN

Description: Friendly interface, PLC computer touch-panel screen control system. Non-hydraulic design, no pollution, low noise, best for using in dustless room. Servo motor control feeding (for EVA sheet cutting tolerance +/-1mm). Modulating control for tension control, it keeps cutting stable. Anti-static PU roller drive for reducing scrape happened. Optional devices: Shaftless unwind stand (electrical left/right moving), EPC (Edge Position Controller), Slitter, Punching device (electrical left/right moving), Automatic stacker, Static eliminating device,

Blown Film and Recycling Machines (Chinese Version)- POLYSTAR | CHINAPLAS 2021

PRM Media Channel once again happy to share the great honor of the cooperation with CPRJ, the official media group of CHINAPLAS. Through this cooperation, we aim to provide insights into the Plastics and Rubber industry by the sharing of experts. In this video, we have invited Mr. David Lo, Chief Marketing Officer, to share his knowledge and the overview of Blown Film Extrusion Machines and Plastics Recycling Machines markets. POLYSTAR Machinery is one of the most famous manufacturers especially in recycling machines in Asia with more than 30 years of experience. Besides recycling machinery, the company also well known around the world with its blown film machine lines. Most of the customers of POLYSTAR buy several sets of blown film machines as well as recycling machines together to set a complete line in their factories and contribute to the circular economy. In this video, our PRM Director Alice will be carrying the interview with the CMO Mr. David Lo. During the interview, Mr. David Lo is explaining the advantages for the customers having both blown film machines and recycling machines from POLYSTAR. The following, interview covers several topics including: 1. Advantages of POLYSTAR recycling and blown film machines 2. POLYSTAR contribution to circular economy and examples 3. Simplifying machine design for ease of use 4. Vision and development in 2021

T-Shirt Bag Making Line with Carton Packaging Line|JIT-SS 4 sets full auto. in-line|JANDI'S

#PlasticReuse #MachineManufacturer #PlasticRecyclingMachine 00:00 Opening 00:08 Blown Film 00:28 Machine current speed 00:37 Cutting, Sealing & Punching 00:54 Sending finished bag to Carton Packaging Section 01:07 Take-up Tower & Printing 02:27 Carton Packaging Proccess 05:04 Ending --- Website : www.jandis.com.tw & www.inflationmachine.com Facebook : www.facebook.com/JANDIS.JIT Email : [email protected]

Plastic Recycling Machine, Repro-Flex | POLYSTAR

【Machine Features】 The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line. The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption. Simple in Design. Flexible in Operation. POLYSTAR is able to customize its machines regarding customers’ needs. How this pelletizing system works: 1. Feeding a. By belt conveyor Feeding of scraps is easy and automatically controlled depending on the amount of material input. b. By Nip roller Film-on-rolls can be fed at the same time. 2. Cutting and compacting The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. 3. Degassing system The two-zone degassing can process plastic film with larger printed areas. 4. Filtration Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking. 5. Pelletization Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head. 6. Final Product Round-shaped recycled pellets are produced and cooled inside the water ring immediately. 【Company Intro】 Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

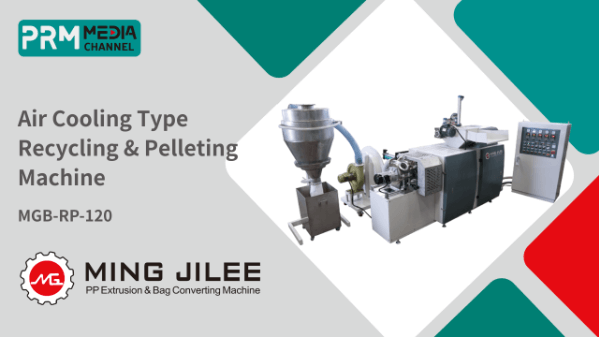

Air Cooling LD/HDPE Recycling Machine, MGB-RP-120 - MING JILEE

Air Cooling LD/HDPE Recycling machine is designs for re-pelletizing PE plastic waste material / t shirt bag die cut wasteThe material can be PE blown film waste, T shirt bag handle die cut waste, etc... Air Cooling Type Plastic Recycling Machine is equipped the power save, the SCR power regulator control. The real power consumption is around 15~20 kg. 1. Machine Specification: (1) Machine dimension a. Main machine : 2,770 (L) × 2,530 (W) × 2,060 (H) mm b. control box : 920 (L) × 420 (W) × 1,660 (H) mm (2) Machine weight : 2,430 kg (3) Power preparation : 45 kg (4) Power consumption : 20 kw 2. Machine Performance: (1) Applicable resin : LDPE / LLDPE / HDPE Waste Film (2) Output a. LD/LLD PE : 50 - 60 kg/hr b. HD/ PE : 40 - 50 kg/hr Air Cooling LD/HDPE Recycling Machine Features: (1) SCR power regular for saving power (2) Rotating die cutting head to get good quality of cutting shape (3) Less space required (4) Extra Cooling fan to cool down the PE material. Air Cooling Type Plastic Recycling Machine Further information: https://www.mingjilee.com/en/product/...

Accumulator Head Blow Molding Machines | FONG KEE

Accumulator Head Blow Molding Machines | FONG KEE Specializes in Accumulator Head Blow Molding Machines, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Accumulator Head Blow Molding Machines manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Accumulator Head Blow Molding Machines and etc. If you are looking for good Plastic Blow Molding Machine Supplier, please feel free to contact us.

Food Packaging Solutions | AI SHIN Interview

At the recent TAIPEI PACK exhibition, PRM Media Channel had an interview with AI SHIN MACHINE CO., LTD. to discuss about the current situations in the packaging industry, upgrade in the service of the company due to current pandemic, also the machinery showcased. AI SHIN is famous for its Automatic Filling & Sealing Packing Machines. The company specialized in manufacturing high speed packing machines for food, filling and sealing liquid cups such as yogurt, juice and water cups. Let us know your opinion and the inquiry in the comment section. Stay tuned for the forthcoming interview videos and remember to subscribe to our social media channels for the similar videos!~ MAIN PRODUCTS/SERVICES OF AI SHIN: Automatic Filling Machine, Automatic Sealing Machine, Rotary Type Filling Machine, Filling & Sealing Machine, Bag Sealing Machines, Sealing & Packing Machines, Semi-automatic Sealer, Rotary Type Sealing Machine, Fully Automatic Box Filing & Sealing Machine for Butter, Capping Machine for Butter, Yogurt Packaging Machine, Pudding Filling & Sealing Machine, Frozen Food Filling & Sealing Machine, Cup/Bowl Instant Noodle Packing Machine, Packing Machinery, Cap Sealing Machine, Jam Cap Sealing Machine, Butter Filling/Sealing Machine, Cup Filling Sealing Machine ***

Plastic Recycling & Pelletizing Machine | GEORDING

【Product Line】 Plastic recycling machine Compounding machine Dyeing & Pelletizing Automatic batch weighing and mixing system Washing line Rubbing drying machine Powerful crusher Shredder Plastic flat board extruder Refuse derived fuel (RDF) 【Company Intro】 GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well.

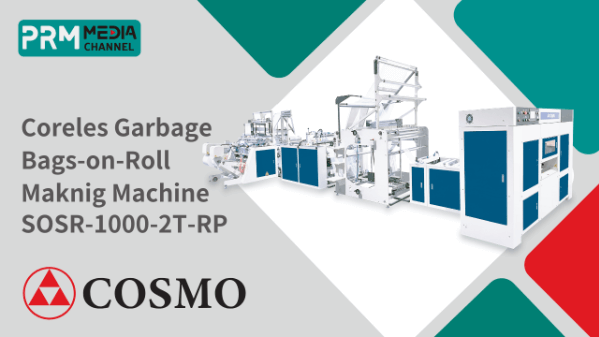

Coreles Garbage Bags-on-Roll Maknig Machine SOSR-1000-2T-RP | COSMO

Flexible production with star sealing and bottom sealing. Shuttle system & 4 shafts re-wind system for stability and high out put. Servo driven system for high production capacity. From film roll to finished bag roll, computer control over the entire process. It's easy to adjust the bag length, film tension, and production speed on touch screen. Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed. Auto reel changing device and bag pull off device on re-winder. Automatically stop on miss-color scanning / film breaking / running out of film. MODEL SR(2)MR(1)-1000-OS-2T-R4S Bag Length 350 - 1500 mm Finished Product Ø150 x 600 mm (single line) Ø150 x 250 mm (2 lines) Film Thickness 0.008 - 0.060 mm / layer (bottom seal) 0.008 - 0.035 mm / layer (star seal) Film Roll Size Ø1000 x 900 mm (single roll for bottom sealing) Ø1000 x 500 mm (2 rolls for star sealing) Production Speed 150 meter / min / line (max) Power 220V, 3Phases, 50/60HZ, 30KVA Heater 6.2 KW Required Air Compressor 6HP (not included) Dimension L10000 x W2600 x H2500 mm * 規格如有變更改進,恕不另行通知。

Shanghai World of Packaging (swop) 2024

Messe Düsseldorf (Shanghai) Co., Ltd. and Adsale Exhibition Services Ltd. will join hands to present the Shanghai World of Packaging (swop) from 18th to 20th November 2024 at Shanghai New International Expo Centre (SNIEC). As a member of the interpack alliance, in addition to continuing to exhibit the packaging industry chain, swop will discuss industry-leading keywords with packers, brands, OEM/ODM, including lightweight, light assets, youth, intelligence, personalization, new materials, new technologies, sustainability, new design trends and other popular topics, sharing packaging cutting-edge concepts and technologies. From materials, equipment, and products to design and marketing, swop is definitely your 360° solution provider in the packaging industry! Find out more at https://adlnk.cn/A3Qm7K5

Upstream and Midstream of Taiwan Automation Manufacturing | What To Say EP16

Have you ever wondered why Taiwan is an automation and automotive parts manufacturing stronghold? In this episode, you will be explaining the first two streams, which are upstream and midstream, which are the initial points for the following procedure of the automotive industry.

TAIPEIPACK 2023 On-site Tour| PRM-TAIWAN

TAIPEIPACK 2023 exhibition tour is coming! Follow Daniel to learn about Taiwanese packaging manufacturers And the first-hand industry information!

Current Situation in Indian Extrusion Market | CCM India Interview

At the end of 2020, we had an online interview with Mr. Prashant Tanna from CCM India(Chichang Machinery India). At the interview, we have discussed various topics related to the plastics and rubber industry. Mr. Tanna sincerely replied to our questions and shared a deep insight especially about the plastics extrusion machinery market in India. We are grateful for the insight that we gathered from Mr. Tanna about the current situation of the Indian market, travel restrictions, benefits of having an agent in the local market, and so on. Let's watch the interview video together and leave your comment at the comment section!

2024 CHINAPLAS Interview | BoReTech

We are here with Mr.Alan Ou from ZHEJIANG BORETECH ENVIRONMENTAL ENGINEERING CO., LTD. at the CHINAPLAS. BoReTech is a leading company in the plastic recycling industry, that strives to solve plastic waste and give it a second life. With more than 30 years of experience in the industry, BoReTech can process different materials from different countries and gain know-how experience.

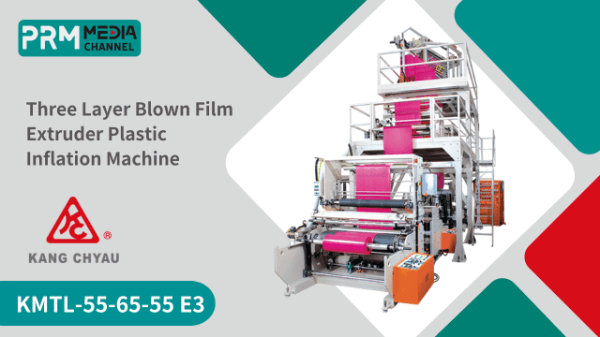

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU

Introducing three-layer blown film extruder machine, in another name called three-layer plastic film inflation machine. From one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the contact button. For any assistance, PRM will be more than happy to assist, please use CONTACT PRM button to leave a comment below. Then we will reply and contact you asap. Machinery in the video: THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE | Model No: KMTL-55-65-55 E3 Film Width: 500-1800 mm Screw Diameter: Ø 40-45-40/45-55-45/55-56-55 mm Suitable Materials: HDPE/LDPE/LLDPE/mLDPE

Injection Molding Machine | CLF

Injection Molding Machine - Chuan Lih Fa Specializes in injection molding machine, CHUAN LIH FA MACHINERY WORKS CO., LTD. was founded in 1966, backed up with 40 years manufacturing injection molding machine, multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer experience. CLF Supply maximum injection machine machine all over the world. Precisely productive equipments and rigidly productive procedures have providing customers with satisfied multi color injection molding machine, All electric molding machine, plastic injection molding machine, plastic injection mold, injection molding machine manufacturer quality to help them getting most profit.

Haitian Mexico Interview Part 1 | Current Situation in Plastics and Rubber Industry

Haitian Mexico Interview Part 1 | Current Situation in Plastics and Rubber Industry As PRM Media Channel, we had a video conference with one of the greatest Injection Molding Machine Industry from Mexico, Haitian Mexico! The Deputy General Manager of HAITIAN MEXICO, Jose Antonio Barroso, talked about the company’s profile and the current situation of COVID-19 in Mexico, the challenges they are having due to the pandemic, and their solutions to overcome those challenges.