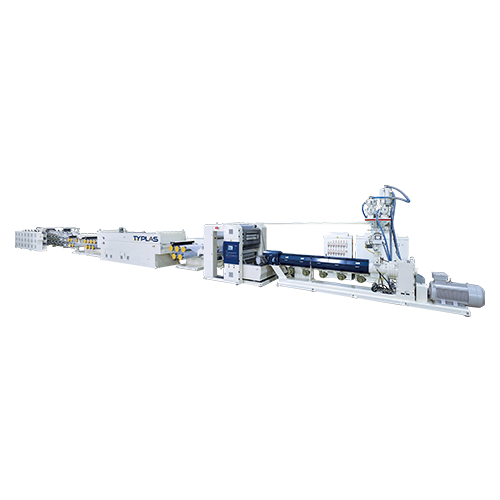

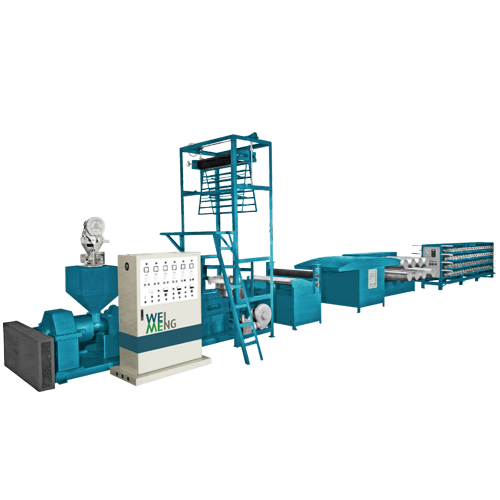

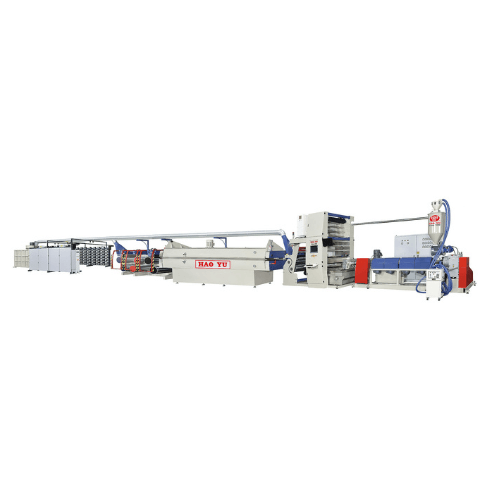

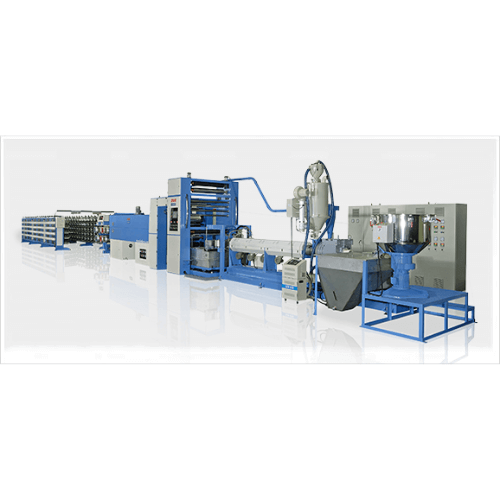

TLFB series is mainly used in PP fibrillating tape line production, it used for twisting by twisting winder into Carpet Backing, Artificial Lawn or Grass, Ropes, Sewing Yarn, Packaging Cords.

- Max. speed: 250 m/mins

- Max. capacity: 500 kg/hr

- Special screw design to produce high quality and stable discharge.

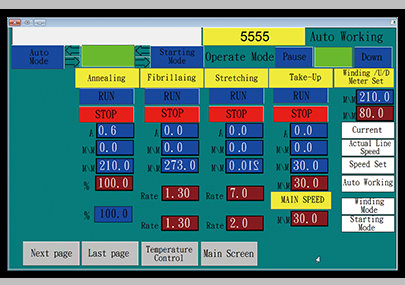

- Improve the physical property of fibrillating tape to the highest tensile strength and tension PLC programing and human machine interface with interlocking operation.

- Stretching oven with airflow and temperature stability design. Tape winder can set the diameter value of tape for winder change warning by LED light.

- Machine customization.

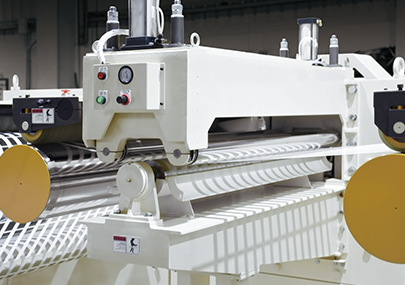

Inverter type and automatic tension control winder, the light-weight design of the tape guide slide achieves power savin

Fibrillating device with pneumatic lifting(air pressure)

Front and rear two-component strip edgy device can be exchange for increased productivity

PLC program control & HMI interface, easy to operate and data memorize

Quench take-up unit, with extrusion device, film cooling forming, and water removal system to keep the film even

Double layer auto filter change and T-die thermal insulation design.

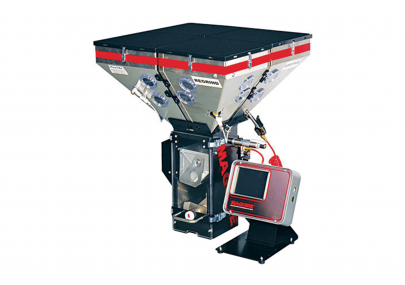

MAGUIRE blender(optional), and its function is to automatically cut and mix according to the proportion of raw materials

|

ITEM/MODEL |

TY-TLFB100-1000-30HF-ST1 |

TY-TLFB115-1300-42HF-ST1 |

TY-TLFB125-1500-54HF-ST1 |

|

Max. Capacity |

300 kg / hr |

400 kg / hr |

500 kg / hr |

|

Max. Line Speed |

250 m / min |

250 m / min |

250 m / min |

|

Denier |

4500 - 22000 |

4500 - 22000 |

4500 - 22000 |

|

Screw Diameter / Multiple |

100 mm / 34D |

115 mm / 34D |

125 mm / 34D |

|

T-die Width |

1000 mm |

1300 mm |

1530 mm |

|

Effective Width |

900 mm |

1190 mm |

1400 mm |

|

Auto Tension Take-up Winder |

30 pcs |

42 pcs |

54 pcs |

|

L x W x H |

39000mm × 4700mm × 4050mm |

41000mm × 4900mm × 4150mm |

43000mm × 5100mm × 4250mm |