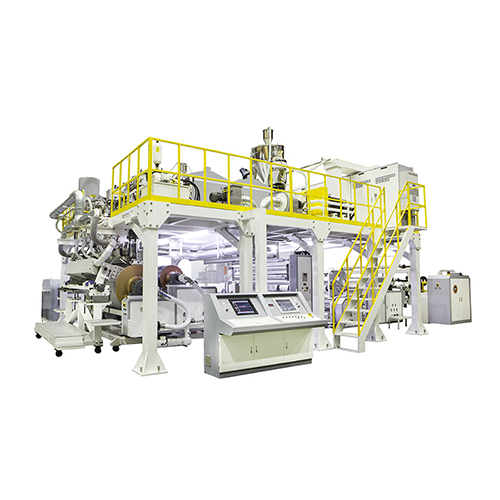

-MONO CAPA, DOS CAPAS, TRES CAPAS Y CINCO CAPAS

-UN COLOR, DOBLE COLOR, HASTA 4 COLORES.

| Resin |

HDPE, HDPE+LDPE/LLDPE+CALCIUM CARBONATE+RECYCLED |

| A/B/A layer structure |

15% -20% / 60%-70% / 15%-20% |

| A layer | 100% virgin HDPE |

| B layer |

Virgin material + 40% Calcium Carbonate+ recycled blend + masterbatch |

| Film Size |

1300 mm(Max.) |

| Film Thickness |

0.015mm - 0.05mm |

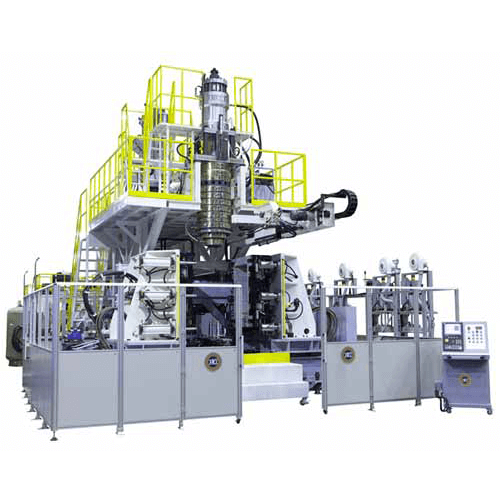

| Extruder |

1 set, 55mm dia.,L/D=28:1 smooth bore type 1 set, 65mm dia.,L/D=28:1 with grooved feeder |

| Main Drive |

30HP AC motor with vector inverter x 1 set 50HP AC motor with vector inverter x 1 set |

| Extrusion output |

100-140 kgs/hr |

| Line speed |

30-80M/MIN |

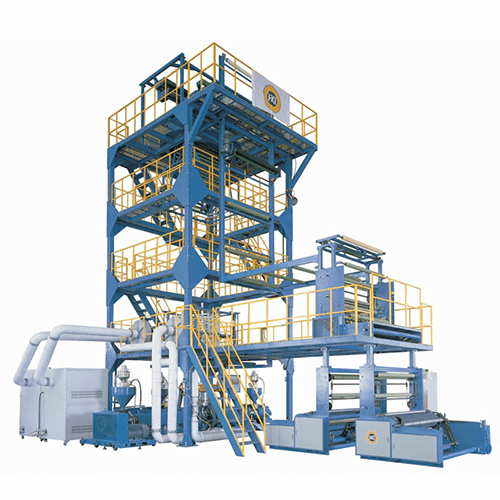

| Tower height |

7000MM |

| Extruding Die Size | 160mm dia |

| Haul Off Unit | With nip roller 1400 mm width |

| Winder | Surface friction type/ Single station/ Film cutting by air knife |

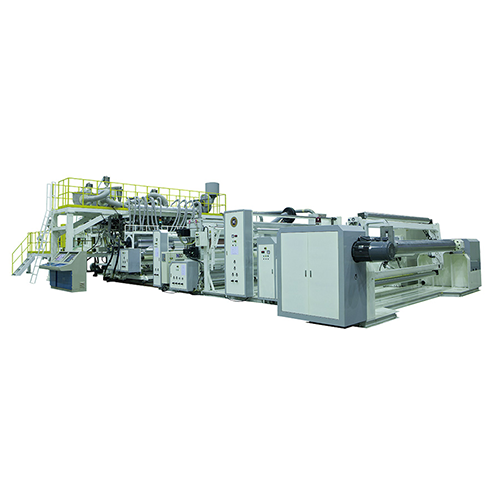

| Resin |

HDPE, HDPE+LDPE/LLDPE+CALCIUM CARBONATE+RECYCLED |

| A/B/A layer structure |

15% -20% / 60%-70% / 15%-20% |

| A layer | 100% virgin HDPE |

| B layer |

Virgin material + 40% Calcium Carbonate+ recycled blend + masterbatch |

| Film Size |

750mm(Max.) |

| Film Thickness |

0.015mm - 0.05mm |

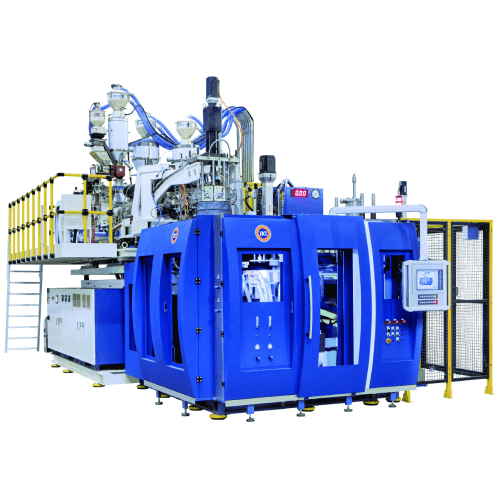

| Extruder |

2 sets, 45mm dia.,L/D=28:1 smooth bore type |

| Main Drive |

20HP AC motor with vector inverter x2 sets |

| Extrusion output |

80kgs/hr |

| Line speed |

30-80M/MIN |

| Tower height |

5000MM |

| Extruding Die Size |

75mm &100mm dia. |

| Haul Off Unit | With nip roller 800 mm width |

| Winder | Surface friction type/ Single station/ Film cutting manually |