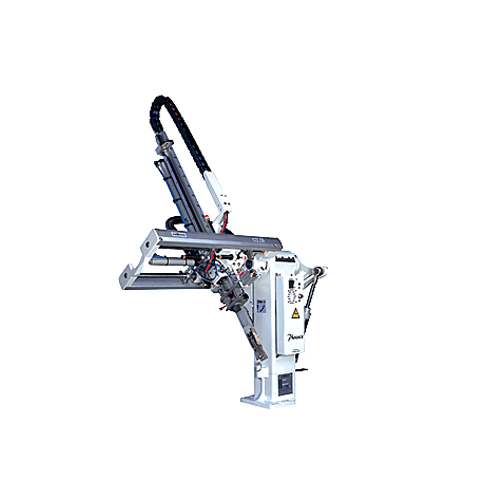

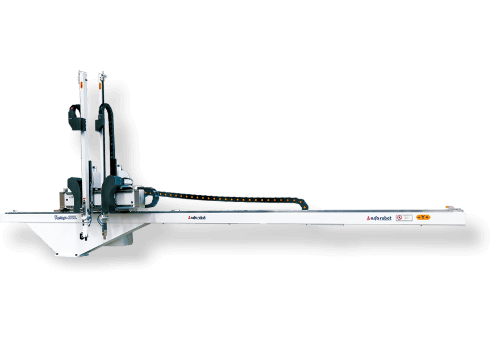

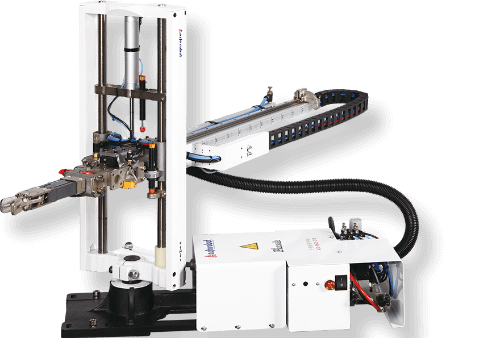

Clasificación: Robots de tipo transversal

País: Taiwan

Teléfono: 0425654888

Fax: 886-4-25607888

Persona de contacto: Ivan

DIALOG CONTROLLER EASY TO CONTROL

- The Control system meets CE, SPI and EUROMAP Standards, which are compatible with injection molding machines all Over the World.

- Remote wire Controller with LCD display for easy reading. The screen capacity is 120 Chinese characters.

- Choice of Chinese, English, Portuguese and French display on SCreen.

- 16 bit CPU provides powerful editing functions for deletion, insertion and replacement.

- The program copy function, in Conjunction with the edit and modification function provides easy program editing and modification.

- 60 sets standard programs Combined with 40 sets editing programs meet requirements for any type of mold.

- The operation panel and the control are Separated, permitting convenient operation at any position. Machine interface contains: mold clamp interlock,injection interlock, mold eject interlock, Safety door control, product counting and Cycle time.

- Specially designed outside mold hold function suits extra high mold and molds with Core cylinders. This prevents molds from bumping against the robot, while allowing the robot to develop its best performance.

- Middle Platen Confirmation Device (optional): A safety guard to prevent the middle platen from bumping against the robot, resulting from incorrect positioning of the middle platen.

SUPEROR DERFORMANICE

TENSO ROBOTS - Integrate Fine Features in One

- The traverse stroke is driven by an imported, high performance, frequency change brake motor for variable speed adjustment and the brake can be micrometrically adjusted to meet mold variations.

- The traverse stroke of the product arm is controlled by an encoder, providing 1-9 points of products release (optional).

- The rack and rail on the traverse stroke are constructed of one piece, offering extreme stability and rigidity.

- The sprue releasing position for the sprue arm can be set as desired on the traverse stroke.

- Exclusive anti-braking design. The brake unlock is performed instantly in the event of power failure.

- The take-out stroke for the product and sprue arm employ double linear motion guides providing an effortless, smooth and vibration free stroke.

- The machine has an innovative automatic speed slow-down on the vertical stroke for the product and sprue arm when in manual control mode. This will avoid operation error and provide protection for the mold.

- Advanced injection confirmation signal.

- The specially designed sprue alarm eliminates wire breakage or poor sensitivity problem, which usually occurs on a magnetic spring sensor or proximity sensor. The service life can reach over 10 years.

- A large, durable, flexible strip is provided to prevent the electrical wires and air circuit pipes from being damaged.

- The product and sprue arms feature fast pick and slow release, which provide a safer working area.

- The gripping, suction and holding pressure on the product arm can be adjusted to prevent damage to the product surface.

- The PU hoses and quick connectors in pneumatic circuits employ imported high quality parts for crack-free performance. The service life can reach over 10 years.

- The sprue picking position can be adjusted to meet sprue variations.

- All components on this robot are made by modular manufacturing for superior interchangeability.

- The barrels for the product arm and sprue arm are manufactured from Aluminium alloy, featuring less weight, high durability, and wear-resistance. High stability in fast operation cycles.

- Equipped with a large capacity air reservoir to minimize air pulsation, while ensuring stable motions (TEM series).

- Heavily constructed throughout. Fast cycle time and maximum operation stability.

- Comprehensive motor positioning systems are easy for Operation and jig installation (TEH & TEM Series).

- Specially designed double action arm drop prevention for maximum safety.

- The TEM Series is designed with double linear motion guides that increase loading capacity of arm and service life. The N type is a two-section configuration to reduce installation height, making the robot suitable for low-roof factories.

- The second step of the vertical stroke is transmitted by a steel reinforced belt. Simultaneous motions for the first and second strike give fast stroke speed (TEH & TEM series).

| Model | TEM-1000(SN) | TEM-1200(SN) | TEM-1400(SN) | TEM-1600(SN) | TEM-1800(SN) | TEM-2000(SN) |

| Suited for injection molding machine | 350-450 Tons | 550-650 Tons | 650-850 Tons | 850-1000 Tons | 1000-1600 Tons | 1600-1800 Tons |

| Power source | 220V±10%, 50/60HZ | |||||

| Max Electric consumption | 5A | |||||

| Air pressure | 6kg/cm2 | |||||

| Drive system | Frequency change motor | |||||

| Vertical stroke (Z) mm | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 |

| Take-out stroke (Y) mm | 400 | 500 | 500 | 600 | 600 | 600 |

| Traverse stroke (X) mm | 1670 | 1910 | 1910 | 2390 | 2630 | 3270 |

| Posture | 90° | |||||

| Max grip weight (Jig weight included) | 8kg | |||||

| Air consumption ℓ/min(ANR)( Pressure 0.5MPa ) | ||||||

| 104.9 | 121.1 | 143.5 | 160.3 | 174.3 | 188 | |

* "SN". Single Arm,Double Sections, "DN": Double Arms,Double Sections, "A". Product Arm, "B". Sprue Arm.

* All specifications, dimensions and design characteristics shown in this catalogue are subject to change without notice.

| Model | TEM-1000(DN) | TEM-1200(DN) | TEM-1400(DN) | TEM-1600(DN) | TEM-1800(DN) | TEM-2000(DN) |

| Suited for injection molding machine | 350-450 Tons | 550-650 Tons | 650-850 Tons | 850-1000 Tons | 1000-1600 Tons | 1600-1800 Tons |

| Power source | 220V±10%, 50/60HZ | |||||

| Max Electric consumption | 5A | |||||

| Air pressure | 6kg/cm2 | |||||

| Drive system | Frequency change motor | |||||

| Vertical stroke (Z) mm | A:1000, B:1050 | A:1200, B:1250 | A:1400, B:1450 | A:1600, B:1650 | A:1800, B:1850 | A:2000, B:2050 |

| Take-out stroke (Y) mm | A:400, B:150 | A:500, B:150 | A:500, B:150 | A:600, B:150 | A:600, B:150 | A:600, B:150 |

| Traverse stroke (X) mm | 1670 | 1910 | 1910 | 2390 | 2630 | 3270 |

| Posture | 90° | |||||

| Max grip weight (Jig weight included) | 8kg | |||||

| Air consumption ℓ/min(ANR)( Pressure 0.5MPa ) | 135.8 | 157.5 | 185.4 | 207.7 | 227.2 | 246.7 |

* All specifications, dimensions and design characteristics shown in this catalogue are subject to change without notice.