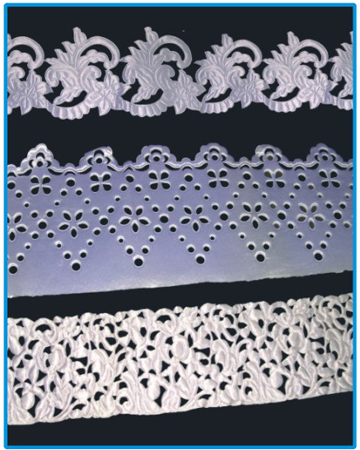

To make wider than 80mm width lace

1. Use ultrasonic energy to cut , weld, seal, seam, hole, emboss, stitch, slit, form, color transfer & fold

2. No need for traditional needle threading.

3. Processing without burrs, wrinkles, shrinkage。

4. Can work continuously for mass production, can work curves; easy to change rollers.

5. Can print color on the lace with colored paper

6. Accurate & durable alloy roller are designed by computer aid &made with sculptural molds

7. No smoke, no sparks, avoid high frequency and heat cutting danger

8. No preheating, processing can be done at the start, easy to operate, low labor costs

9. Thousand of pattern roller designs available

10. Max. working width is 198mm.

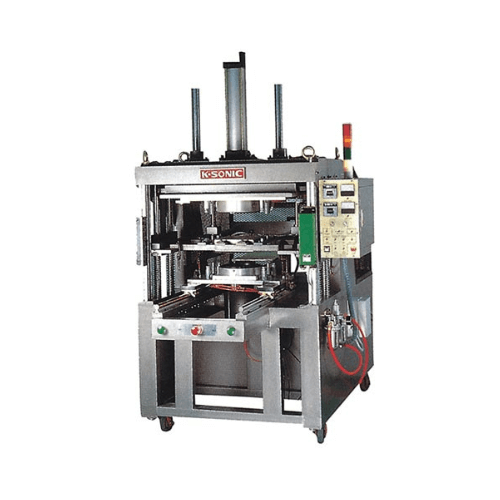

11. Using auto tuning Ultrasonic system

12. Overload protection to avoid the ultrasonic system damaging

13. With frequency display to be easily observe the working condition of machine

| SERIAL | |||

| MODEL | KS-200A | KS-200A ARCH | |

| SPEC. | OUTPUT | 2000W | |

| FREQUENCY | 20KHZ | ||

| POWER | 220V 1P 20A 50/60 Hz | ||

| AIR SOURCE | 7Kg / cm² | ||

| SEWING SPEED | 0~9 m/min. | ||

| ALTERNATIVE ROLLER | 198MM | ||

| WORKING TABLE (mm) | W1200*L600 | W1800*L600 | |

| DIMENSION | W1400*L600*H1400 | W2000*L650*H1400 | |

| WEIGHT | 250KG | 400KG | |

| THICKNESS OF FABRIC | 0.0.~0.5mm | ||

Suitable material :

Fabric of synthetic composition over 65%, polyester, nylon, tetoron, TC, sponge, non-woven fabric, thermo-plastic films, steel wire feed in the ribbon, hot printing paper