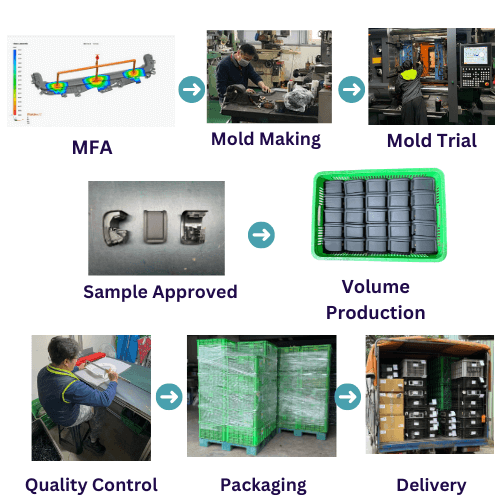

From Concept to Delivery — Ensuring Precision and Reliability

At our facility, every injection molding project follows a well-defined, 8-step workflow designed to ensure optimal quality, efficiency, and customer satisfaction. From initial mold flow analysis to final delivery, we emphasize precision at every stage. Whether you need a customized component or large-volume production, we deliver with consistency and care.

Workflow Overview:

-

MFA (Mold Flow Analysis): Simulate mold performance before production to identify potential defects and optimize gate and runner design.

-

Mold Making: Skilled technicians craft the mold using advanced machining equipment for durability and precision.

-

Mold Trial: Conduct initial test runs to verify mold performance and ensure part accuracy.

-

Sample Approved: Obtain client approval on the first article for dimensional and cosmetic standards.

-

Volume Production: Begin mass production using validated mold settings to ensure stable output.

-

Quality Control: Each batch is carefully inspected to maintain consistent product quality.

-

Packaging: Products are securely packed based on export requirements.

-

Delivery: Final products are shipped with full traceability and documentation support.

Let us be your trusted partner in plastic part manufacturing.