CORTADOR DE MOLDE DE ACERO DE ALTA VELOCIDAD HSP-12

CATEGORÍAS : Maquinaria de espuma

Mecanismo de alimentación innovador: en el cual, el sistema de alimentación automática de subida / bajada está diseñado para la altura del material moldeado. Excelente y estabilizada precisión de punto muerto: para lo cual la estructura mecánica sincronizada de doble eje está diseñada para lograr una mayor estabilidad de punto muerto inferior. Mecanismo de ajuste de profundidad de alta precisión: que utiliza una unidad de ajuste fino sincronizada izquierda / derecha para lograr 0,01 mm de precisión de ajuste fino. Función de guardado de parámetros: para nombrar y almacenar parámetros relevantes después de ser configurados. Función en línea de la máquina de moldeo: Para llevar a cabo un control sincronizado con otra máquina de moldeo a través de la operación en línea. Mecanismo de lubricación automática: en el cual, el mecanismo de lubricación automática está diseñado para reducir el trabajo de mantenimiento diario.

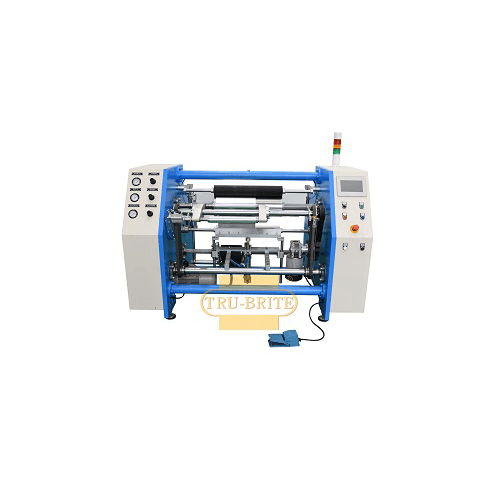

MULTIFUNCTION TWO-SHAFT TYPE SEMI-AUTOMATIC ALUMINUM FOIL & CLING FILM REWINDER (SRB-A-2S 20-50)

CATEGORÍAS : Cortadoras y rebobinadoras

SRB-A-2S, the two shaft type semi-automatic, multiple functions rewinding machine Suitable for rewind aluminum foil and PE, PVC cling film. The mother roll available width is from 200-500 mm. The finished paper core’s I.D. is from 25-50 mm. This model is carried a brake system, controls the brake power accurately. Users can check the data of brake output and single product weight anytime. SRB-A-2S is able to set prior deceleration points of every speed level. Users only need to adjust rewinding speed afterwards. Machine will regulate deceleration points automatically by the settings. It has automatic functions of cutting and fixed length feeding. Users will thread the material onto paper core more convenient. The whole machine is combined of electronic control, carried with electric motor system; enable more precise and quicker shaft-changing movements. While finished rewinding process, the rewinding shaft will back off by itself. Users can switch to the automatic mode which start machine automatically after shafts are pressed down. Automatic cutting, automatic shaft-changing and shaft pressing, users just need to load & unload products after press start button. Welcome to consult machine with us. We will at your service.

Máquina de Moldeo de Caucho por Inyección de ARRIBA HACIA ABAJO

CATEGORÍAS : Máquinas de moldeo por inyección de caucho

Máquina de Moldeo de Caucho por Inyección de ARRIBA HACIA ABAJO

SEMIAUTOMATIC TRAY SEALER WITH VACUUM AND GAS FLUSHING

CATEGORÍAS : Máquinas de envasado al vacío

Semiautomatic Tray Sealer with Vacuum and Gas Flushing from Jaw Feng Machinery Co., Ltd. is made of stainless steel. Mold is made of aluminum with antioxidant treatment and easy to change over. Two-bottom safety design for mold's in and out. Programmable for data up to 10 set-ups. Each group can operate individually. Vacuum / nitrogen and sealed packaging. Offering lots of models to meet different sizes of trays.

Máquina de punzonado automático

CATEGORÍAS : Punzonadoras hidráulicas

Para perforar en espuma de PU flexible, espuma de memoria, espuma de látex, caucho, PE, EPDM, EVA ... telas, textiles, láminas de plástico ... Etc

Línea de extrusión de láminas de espuma

CATEGORÍAS : Líneas de extrusión de películas y láminas

Foam Sheet Extrusion Line Features : With proper mixing of melted resin & blowing agent, provides most homogeneous mixing. Accurate blowing agent injecting quantity and temperature control to stabilize the foaming process. High level safety control, system will be shut down automatically when extruder motor failure or high pressure.

AUTOMATIC TRAY SEALER WITH VACUUM AND GAS FLUSHING

CATEGORÍAS : Máquinas de envasado al vacío

Automatic Tray Sealer with Vacuum and Gas Flushing from Jaw Feng Machinery Co., Ltd. is made of stainless steel. Outdoor security vacuum cover. When electrical box is opened, it will shut down immediately. Can use multiple die sets and easy to change over, Multi-lingual PLC touch screen with a movable arm. Operate 360°. Every functions on the screen are presented in narrative, simple to understand. Vacuum / nitrogen, vacuum / skin pack, and sealed packaging. Offering lots of models to meet different sizes of trays. Able to work with date injecting, date thermal printing, labeling, aligner feeder, etc.

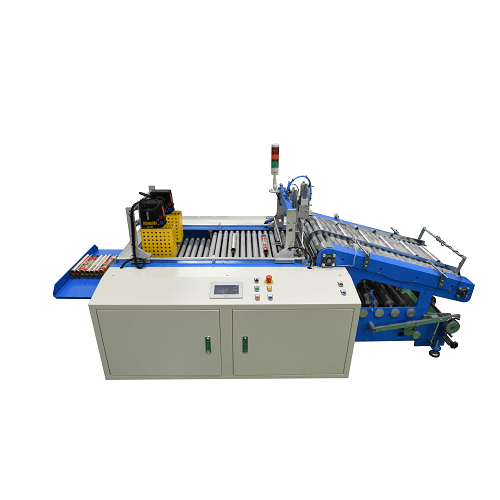

Máquina de unión automática de placas PTR-500

CATEGORÍAS : Laminadoras por Extrusión

Patented Automatic Receiving Mechanism: Performs the material jointing work automatically. Automatic Charging Mechanism: The vacuum robot is used to move the material to the designed position automatically. Servo Transmission Control: Uses 3-axle servomotor to perform high-speed transmission and positioning. Versatile Dimension Flexibility: The parameter fine-tuning can be performed according to the characteristics of different materials. Automatic Feeding Mechanism: Delivers the jointed material automatically. Parameter Storing System: Performs module-based memory for the production figures to facilitate the parameter management.

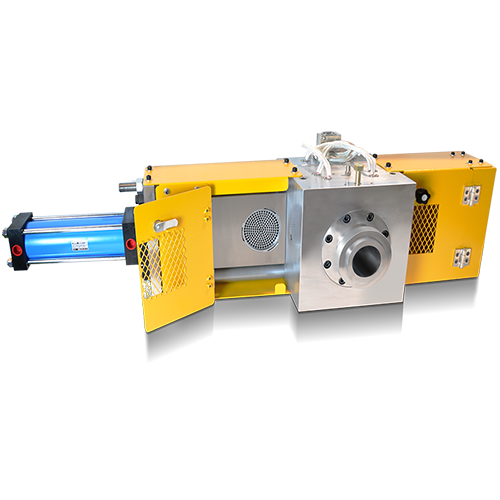

CAMBIADOR DE PANTALLA

CATEGORÍAS : Cambiadores de Filtros / Filtros

CAMBIADOR DE PANTALLA DE PLACA DESLIZANTE HIDRÁULICA CAMBIADOR DE PANTALLA DE PLACA DESLIZANTE DE NITRÓGENO CAMBIADOR DE PANTALLA DE PLACAS DOBLES

AUTOMATIC SHRINK FILM PACKAGING MACHINE (TPG 50)

CATEGORÍAS : Cortadoras y rebobinadoras

Model TPG50, the automatic shrink film packaging machine. A special design for wrap roll products. It can be connected to the back side of rewinding machine as an automatic production line. You can not only make your product refined and protected, but also arrange manpower more effectively. TPG50 is carried 3 conveyors as 3 work areas. It uses conveyors to deliver products to the processing area. You can choose automatic feeding of the material,or feed by detected sensor. As shrinkable films, BOPP, PVC and PE can be used on TPG50. The length of over wrapping film can be set manually or detected by the mark sensor. For packing decoration, you can use printed film; or, equip with a label paper device. The device will insert a piece of label before shrinking. The label will be wrapped inside the film, makes your product eye-catching. The last step, electrostatic device and thermal-wind will perfectly pack your products! Welcome to consult machine with us, we will at your service.

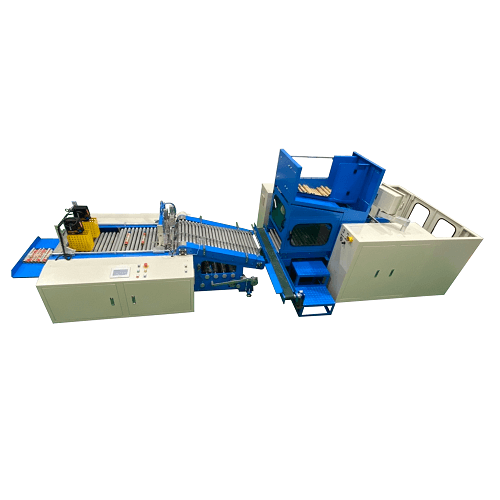

SIX-SHAFT AUTOMATIC ALUMINUM FOIL / CLING FILM REWINDER AUTOMATIC REWINDING & SHRINK FILM PACKAGING MACHINE (AH-6S + TPG50)

CATEGORÍAS : Cortadoras y rebobinadoras

AH-6S connected to TPG 50, the fully automatic production line, fully automatic operation system. Use a conveyor to combine two models for manufacture. Machine will automatically rewind material after input paper core. When the roll is finished and unloaded, it is carried to the packing area for automatic packing process. If the packing function is not used temporarily, TPG50 can be switched to delivery mode. Or use the conveyor which connects 2 machines to unload products from the side. This production line achieves automated manufacture. It saves time and manpower of moving materials and rolls from machine to machine. TRU-BRUTE Machinery always provides the beneficial collocation of machine for you. Welcome to consult machine with us. We will at your service.

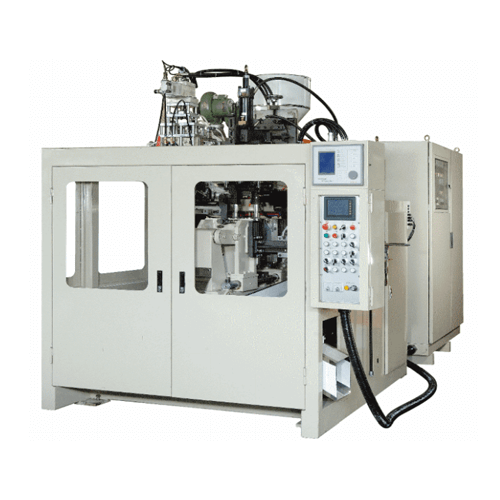

JN Series-Single Station

CATEGORÍAS : Máquinas automáticas de moldeo por soplado

● Tipo hidráulico Máquina de moldeo por soplado automática. ● Diseño de producción automático. ● Diseño de estructura de sujeción de servicio pesado. ● Molde Abrir / Cerrar / Mover por guía lineal de precisión y las botellas terminadas salen en línea para el siguiente proceso. ● Extrusora de transmisión directamente. ● Los desechos centralizan la gestión. ● Control PLC con pantalla táctil para tiempo, presión, flujo, ... etc. ● Las cuchillas de parison diversificadas y las opciones de cabezales múltiples dependen del requisito. ● Sistema de ahorro de energía para el sistema hidráulico.