LATEST UPDATE Suscríbete

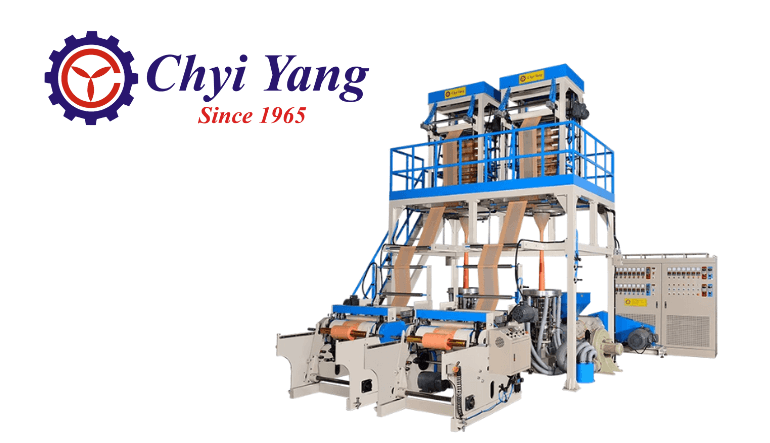

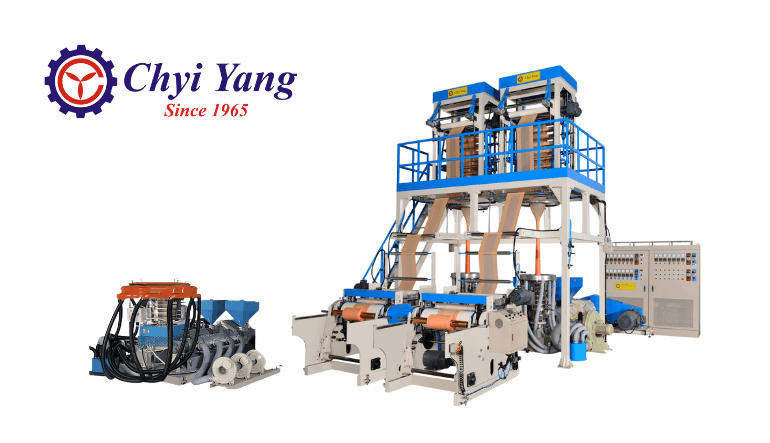

Advantages of ABA Co-extrusion Blown Film Machine

A co-extrusion process uses more than one polymer to form the plastic bubble and therefore more layers to the film. The most prevalent blown film process today is the ABA co-extrusion process. One of CHYI YANG's most popular machines is also the ABA co-extrusion blown film machine. The term ABA indicates the three-layer structure of the film, two outer layers, and one inner layer, hence ABA. The materials of the A layer and B layer are different. The outer layer typically uses new materials, whereas the inner layer uses recycled materials. Using more than one material leads to several advantages and installation adjustments on the ABA blown film machine. As a leading plastic film machinery manufacturer in Taiwan, today CHYI YANG will talk about the advantages of this kind of blown film machine and how it can help your business.

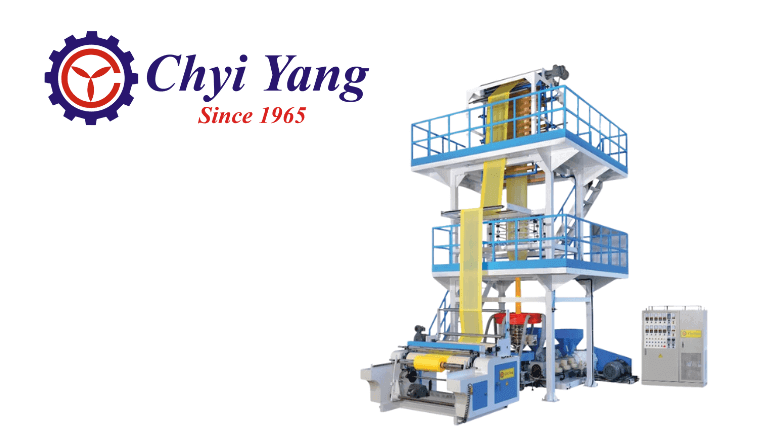

Revolutionizing the Market: CHYI YANG's Smart 5/7-layer Blown Film Machines Lead the ESG Sustainability Trend

Chyi Yang's Smart 5/7-layer Blown Film Machines revolutionize plastic film production, reducing costs and material waste while complying with regulations. Their Auto-recycling blown film machines use precision formula calculations and advanced recycling mechanisms to improve production yield and achieve "ZERO WASTE" while reducing energy consumption to improve competitiveness.

PE Cling Film Market Trend: Sustainability and Clean Production

The use of cling film has substantially expanded in recent years in response to the increased demand from global pharmaceutical and F&B industries. This is especially true considering that manufacturers have developed many special-purpose films to boost market appeal. North America currently dominates the cling film market; however, the market for cling film has become a hot spot for rapid growth due to the urbanization of developing regions in the Asia Pacific, including China, India and Southeast Asia.

The Smart Choice: CHYI YANG Yang's ABA 3-Layer Co-Extrusion Reach the Perfect Combination of High Performance and Precise Cost Control

With consistently increasing sales and highly positive feedback from customers, Chyi Yang’s newly launched ABA 3-Layer Co-Extrusion has quickly gained traction in the market. Its strong competitive edge in reducing production costs, improving efficiency, and maintaining superior product quality has made it a standout performer. The machine’s impressive sales and exceptional customer satisfaction have solidified its position as a rising star in the industry.

CHYI YANG: Transforming Waste into Gold, ABA Co-extrusion Machine Revolutionized Bag Manufacturing

The unique die head design of the ABA co-extrusion machines offers producers cost management flexibility by incorporating an middle layer of recycled material or calcium carbonate compound, effectively reducing raw material expenses. This not only maintains competitiveness in raw material prices but also aligns with environmental trends.