LATEST UPDATE Suscríbete

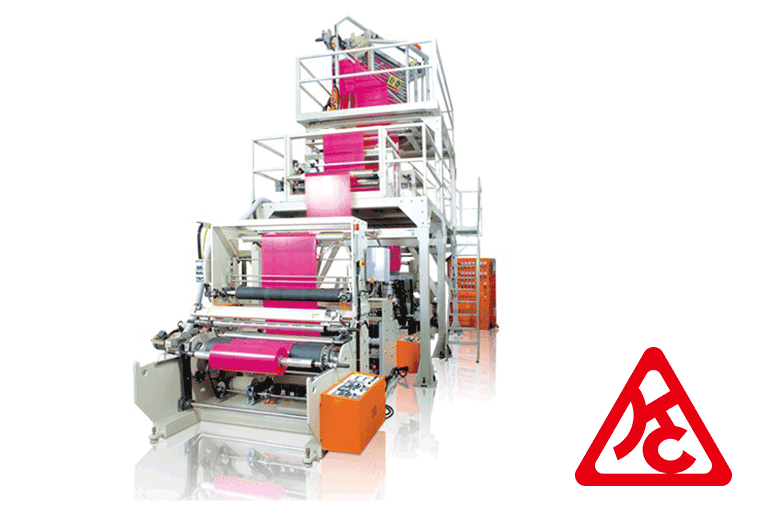

JANDI’S - The Differences in the Nature of PE & Biodegradable Material (PLA/PBAT Based)

According to the material supplier, bio-degradable material cannot be recycled easily. But, if not trying to recycle, the disposal of the waste & die-cut from bio-degradable material will become big additional expenses. Even if you may recycle the bio-degradable material, the time, space and workman ship required for the collection of the waste, will already create additional costs. Because of the above reasons, JANDI’S JIT is the best solution for the production of PLA/PBAT Bio-Degradable T-shirt bags.

KANG CHYAU: Reaching Outstanding and Efficient Solutions on a Changing Market

This past year, 2020, many players from the Plastic and Rubber Industry experienced distresses on two major points, such as how strong the pandemic was going to affect the economic situation and how long it was going to take for its stabilization. In the current year, we continued analysing thoroughly how the industry has been gradually healing and how Taiwanese Manufacturers have been innovating on performance and assistance to bring the best to their customers in these hard times.

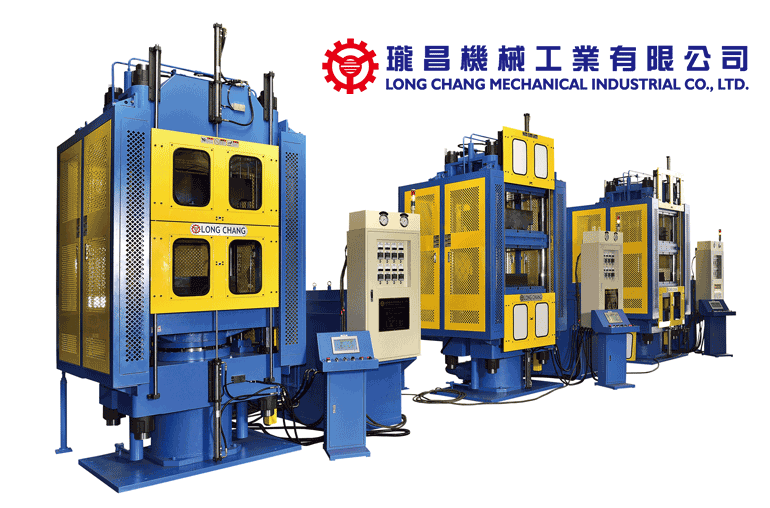

LONG CHANG: Serie FCF- Máquina de Moldeo por Compresión Hidráulica de Aceite de Doble Capa de un Solo Cuerpo

Esta maquina es idóneo para la produccion de asientos de baño o inodoro, urea, melanina, materias primas de baquelita. La salida puede producir dos moldes a la vez para mejorar la producción. Utilice una válvula de flujo proporcional y una válvula de control de presión para garantizar un flujo de presión estable y suave y lograr la mejor eficiencia de producción.

GMA Successfully Overcome 2021 Challenges, and Ready to Continue Giving High Quality Service to the World

This year was though for Taiwanese companies due the outbreak of COVID-19, but for GMA was an opportunity to continue growing on different markets, such as China which is one of its main markets, also it is important to mention that GMA has established at the vanguard in different regions, such India, but also High-End markets such as Japan and Europe...

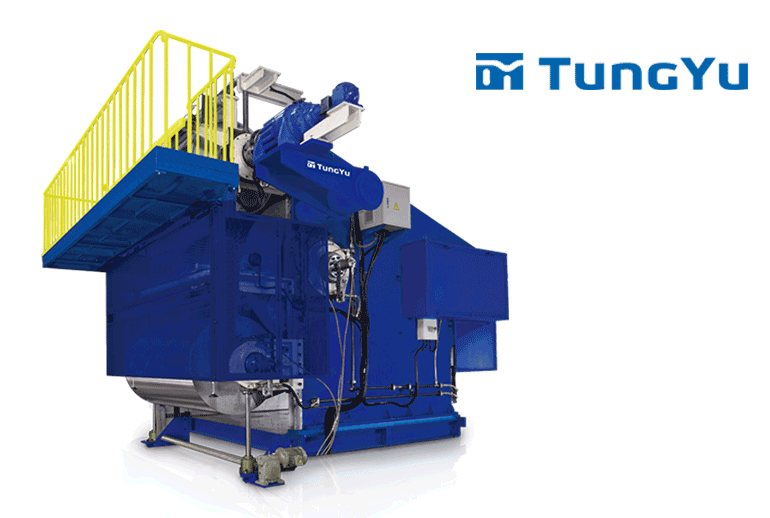

TUNG YU: Rotocure with CE Certificate

Continuous vulcanizing process provides high production efficiency and stable quality. Auto latching chuck for safety and promptly loading/unloading material shaft. Control system by PLC and HMI to easily and precisely set up temperature, pressure, speed and other production parameters.

Estrategia de sostenibilidad en la era de la neutralidad de carbono

El aumento de las emisiones de carbono conduce al cambio climático global y da lugar a un impacto amenazador sobre la sostenibilidad de la sociedad humana. Para mediados de siglo, logrando la neutralidad de carbono en todo el mundo, la industria debe reformarse desasociando el crecimiento económico de la utilización de recursos fósiles como el petróleo, el carbón y el gas natural. El impuesto en la frontera del carbono (CBT) se aplicará a las mercancías exportadas a la Unión Europea a partir del 2023 y de esa manera se podrá anticipar en las otras entidades económicas importantes.

TwinScrew explora el comercio ecológico por adelantado

Junto con la legislación completada que restringe el uso de plásticos en la Unión Europea en 2021, los plásticos de un solo uso estarán legalmente prohibidos en China para 2025. Hasta ahora, hay 79 países que cuentan con más del 70% del PIB mundial y tienen su propia restricción legislativa sobre el uso de plásticos. Se estima una tasa del 16% en CAGR para los productos elaborados con materiales de base biológica o biodegradables desde el 2020 hasta 2027.

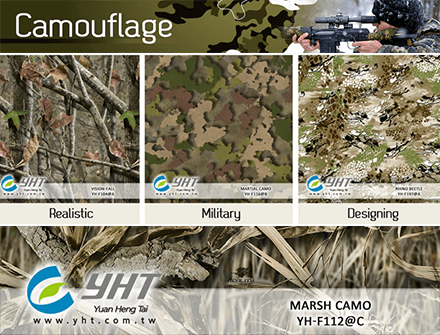

Yuan Heng Tai - All Things You Need to Know About Camo Hydrographic Films

One of the biggest and the most important patterns of Water Transfer Printing is Camouflage.Camo Hydrographic Filmcan be used on different industries, not only in the hunting industry, it can also be applied to related products, such as sun glasses, ear defender, shoes, and other accessories, even for industries that are not related to hunting industry.

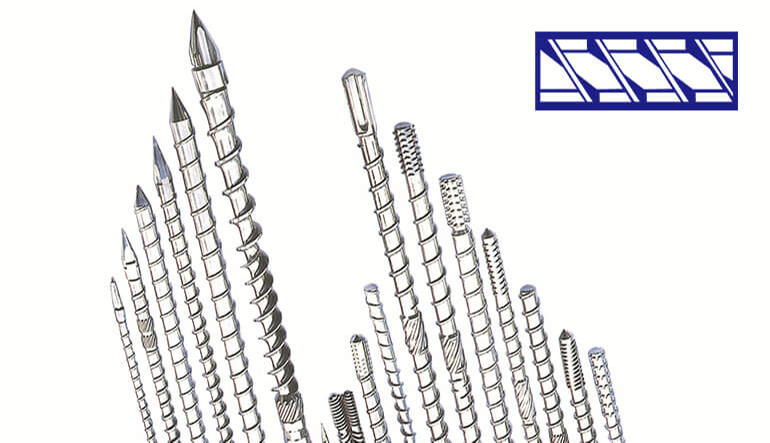

LUNG CHANG Cultivates the Trust of Manufacturers through Customized Screws and Barrels

During pandemic COVID-19 one of the biggest challenges for the plastic machinery industry is the travel and logistics limitations. No matter after sales services of the manufacturers are good, once it comes to the maintenance and part requirements, current transportation and logistics obstacles might cause the manufacturers delay in their business. Therefore, many plastic machine manufacturers prefer to use the parts, such as screws and barrels, that are high quality and meet customers' requirements precisely in their machines. In this case LUNG CHANG is one step ahead in the industry with its reliable extruder screws and barrels as well as injection molding machine screws and barrels.

Lian You Machinery, Innovation in Bag Making Industry and High Quality Service Guaranteed

When companies are going to do big investments, such as buying machinery of different kinds, one of the main concerns is the quality of the supplier’s manufacturing capacity, quality, technology but also after sale service in case of any question or problem they might have after buying a machine. Lian You Machinery (LYM) having experience in the field since 1993, has a clear path on how to keep customers satisfied thanks to their high technical skill and knowledge.

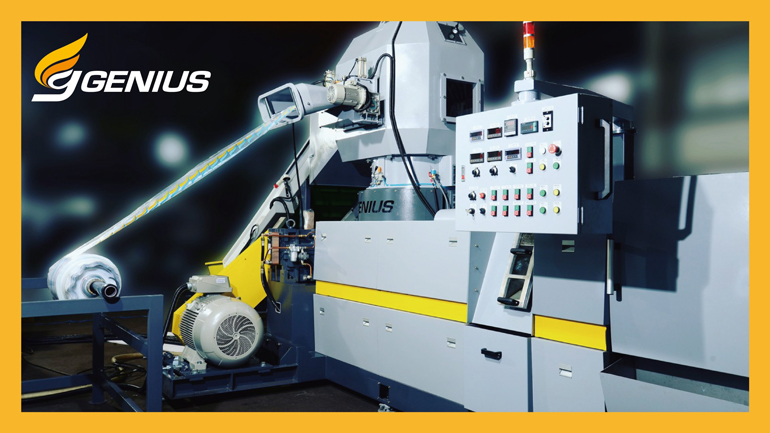

GENIUS - Cutter Compactor Recycling Machine: One Machine for All Types of Materials

In the plastic recycling industry, one of the current main customer demands is to have a recycling machine that can process many different types of plastic materials. GENIUS Cutter Compactor Recycling Machine lines are exactly cut out for these requirements. GENIUS developed these machinery series to meet various customer demands to process different types of plastic materials with an affordable cost.

CHEN WAY - Top 6 Common Problems in HDPE Blow Molding

HDPE Blow Molding is the most economical- highest production output forming process for hollow products: beverage, chemical or pharmaceutical bottles, edible oil jerry cans, chemical drums, etc. And even though you can produce an almost perfect, high quality container, you might encounter different problems along the blow molding process of your products, so it is vital that you can identify where the problem comes from and how to handle it.