Issue 143

Suscríbete

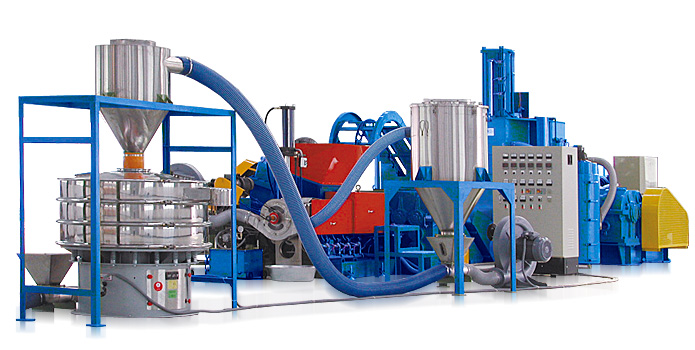

High Filler Modify Compound Making Line – High output and quality standard

JIN KUO HUA PLASTIC MACHINE CO., LTD. founded since 1956 and gains the good reputation in the plastic & rubber fields. JIN KUO HUA specialized in Masterbatch Compound Manufacturing Line, High Filler (CaCo3, TiO2 or Talc) of Modify Compound Making Line and specialized in Wire and Cable industry field of the Soft PVC pellets and Halogen Free Materials (EVA, SEBS, PE base) of compounding pellets manufacturing line. Also JIN KUO HUA designs different kind of the extruder such as profile Extruder, PVC Corrugated Sheet Extruder and PVC Flooring Sheet Manufacturing Line etc.

High Filler Modified Compound Making Line

Main Features

JIN KUO HUA have strong technology background and operation process experiences to conduct strict inspections on all the different kind of products at different stages of manufacturing process to meet client’s expectations such as to adapt some different option auxiliary equipment to reach large output capacity with good quality of the products to aim on our own high standards. So that, our manufacturing line could reach best dispersion with high output capacity in this industry field.

1. Best dispersion result.

2. Products reach FDA standard of the quality.

3. Large output capacity to low the product process of cost.

Auxiliary Equipment

1. Temperature Controller: Good to accelerate the mixing materials of the Temperature.

2. Industry Air Conditioner: Good to conduct with the Cooling Housing to cool the cutting pellets.

3. Water Chiller: Good for the Extruder and Cooling System. Using the Pure water to keep nice and clean circulation status and lower the water consumptions cost also avoid the lime scale to extend the machine life.

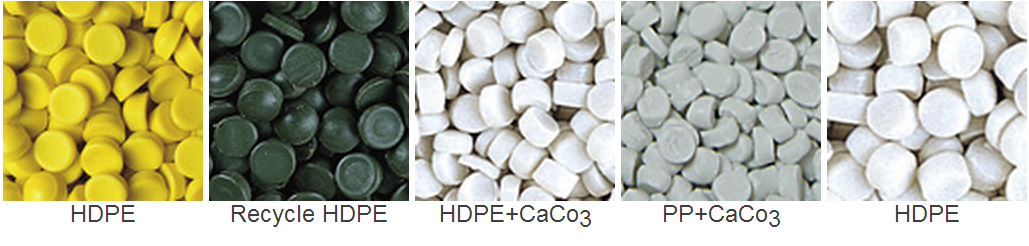

Modify Compound Pellets could be using in most of the products such as:

1. Blow Film Industry

2. Injection Molding Industry

3. Food Container

4. Water Tank

5. Agriculture films

6. Shopping Bags.

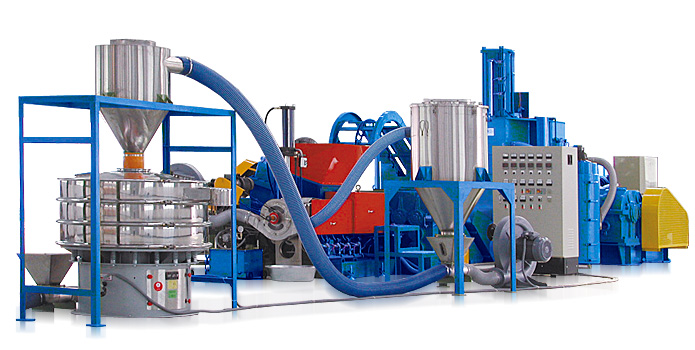

High Filler Modified Compound Making Line

Main Features

JIN KUO HUA have strong technology background and operation process experiences to conduct strict inspections on all the different kind of products at different stages of manufacturing process to meet client’s expectations such as to adapt some different option auxiliary equipment to reach large output capacity with good quality of the products to aim on our own high standards. So that, our manufacturing line could reach best dispersion with high output capacity in this industry field.

1. Best dispersion result.

2. Products reach FDA standard of the quality.

3. Large output capacity to low the product process of cost.

Auxiliary Equipment

1. Temperature Controller: Good to accelerate the mixing materials of the Temperature.

2. Industry Air Conditioner: Good to conduct with the Cooling Housing to cool the cutting pellets.

3. Water Chiller: Good for the Extruder and Cooling System. Using the Pure water to keep nice and clean circulation status and lower the water consumptions cost also avoid the lime scale to extend the machine life.

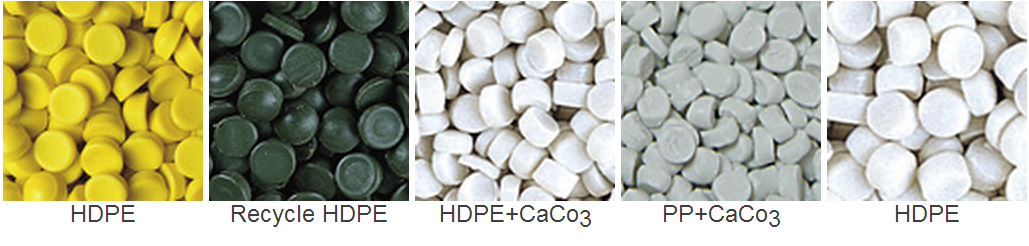

Modify Compound Pellets could be using in most of the products such as:

1. Blow Film Industry

2. Injection Molding Industry

3. Food Container

4. Water Tank

5. Agriculture films

6. Shopping Bags.

7. Woven Bags.

More Information on PRM-Taiwan: www.prm-taiwan.com/com/jinkuohua

SITIOS DESTACADOS

E-News Categories

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos