Issue 145

Suscríbete

How to use hot runner system for molding parts with glass fiber

In order to improve the mechanical properties of rigidity, strength and also for surface hardness. A wide range of polymers are now produced in glass-fiber (varieties %), including PA, LCP, etc. On the other hand, it was found that increasing the glass-fiber also increase the complicate of surfaces wear, erosion, and gate frozen problem. It may damage the mold components and hot runner system. Typically Glass fiber grades are not recommended for hot runner applications. But hot-runner systems can provide an array of benefits, including reduced material use, faster cycles, and overall better part quality.

Let Amold help you maximize the material properties of your Glass Fiber application.

Ann Tong company, the brand with Amold hot runner system, has more than 29-years experiences in the hot runner field and its performance is highly recognized in this area. It provides customer-oriented and all-around services to make sure that its customer will have a highly stable production.

Ann Tong Co. Established in 1989, is a pragmatic, focused, professional and innovation oriented hot runner company. For years, it has been granted various patents and has won a number of awards as follows: Taiwan excellence Award, Innovation Research award, National Invention and Creation Award, the Excellent enterprise of New Taipei City, etc.

Ann Tong also launched “hot runner hospital” program providing all-round consulting service to assist our customers solving the hot runner issues.

As following is a case study:

Productivity from 14,400 (pcs/day) of 3-plate mold to 21,600 (pcs/day) by hot runner mold. Saving in material 15.6 g per mold, and then it can save 56.16 Kg per day, and it can save 7.5 (US$/KG) * 56.16 (KG) = 421.2 US$ per day.

ANN TONG in PRM-TAIWAN : https://www.prm-taiwan.com/com/anntong.html

Let Amold help you maximize the material properties of your Glass Fiber application.

Ann Tong company, the brand with Amold hot runner system, has more than 29-years experiences in the hot runner field and its performance is highly recognized in this area. It provides customer-oriented and all-around services to make sure that its customer will have a highly stable production.

Ann Tong Co. Established in 1989, is a pragmatic, focused, professional and innovation oriented hot runner company. For years, it has been granted various patents and has won a number of awards as follows: Taiwan excellence Award, Innovation Research award, National Invention and Creation Award, the Excellent enterprise of New Taipei City, etc.

Ann Tong also launched “hot runner hospital” program providing all-round consulting service to assist our customers solving the hot runner issues.

The mission statement is “When customers succeed, Ann Tong succeeds.

As following is a case study:

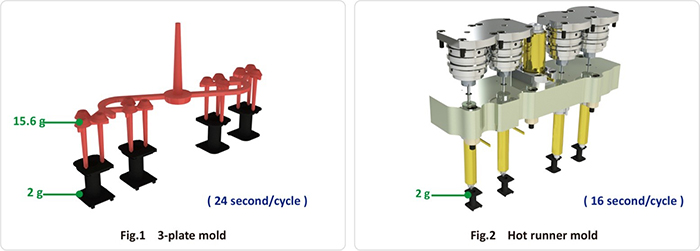

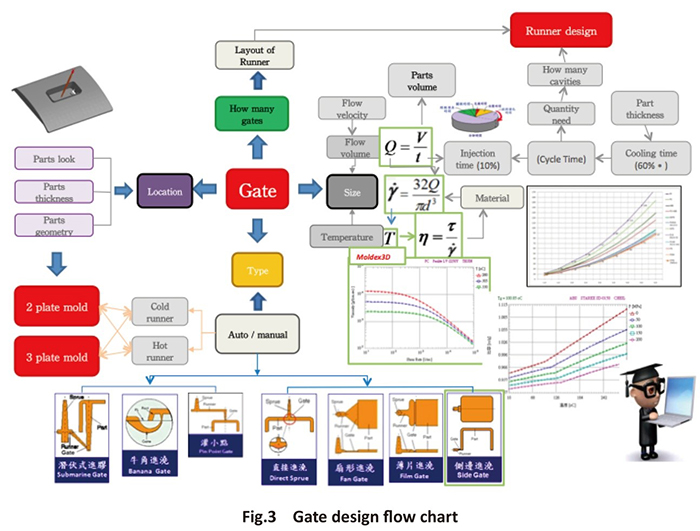

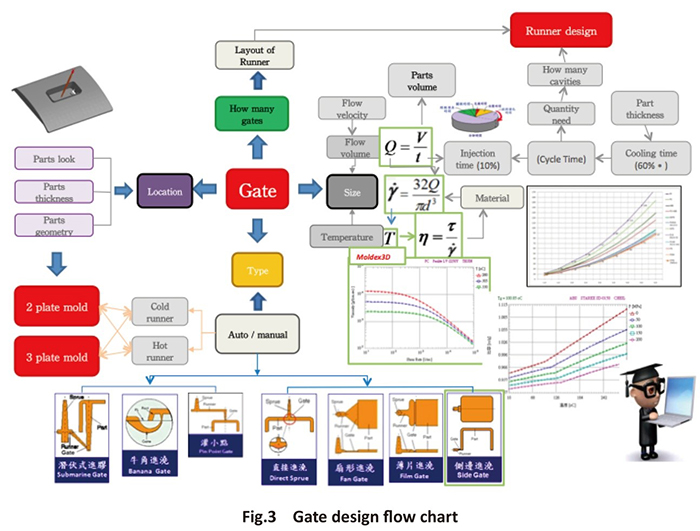

- Mechanical part(weight/part): 2 g/pc.

- Material: PA66 + 40% glass fiber.

- Cavities: 4cavities / mold.

- 3-plate mold: runner 15.6 g/shot. (24 second/cycle)

- Hot runner mold: no waste runner. (16 second/cycle)

Productivity from 14,400 (pcs/day) of 3-plate mold to 21,600 (pcs/day) by hot runner mold. Saving in material 15.6 g per mold, and then it can save 56.16 Kg per day, and it can save 7.5 (US$/KG) * 56.16 (KG) = 421.2 US$ per day.

ANN TONG in PRM-TAIWAN : https://www.prm-taiwan.com/com/anntong.html

SITIOS DESTACADOS

E-News Categories

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos