Issue 148

Suscríbete

Extremely positive feedback from the Russian market

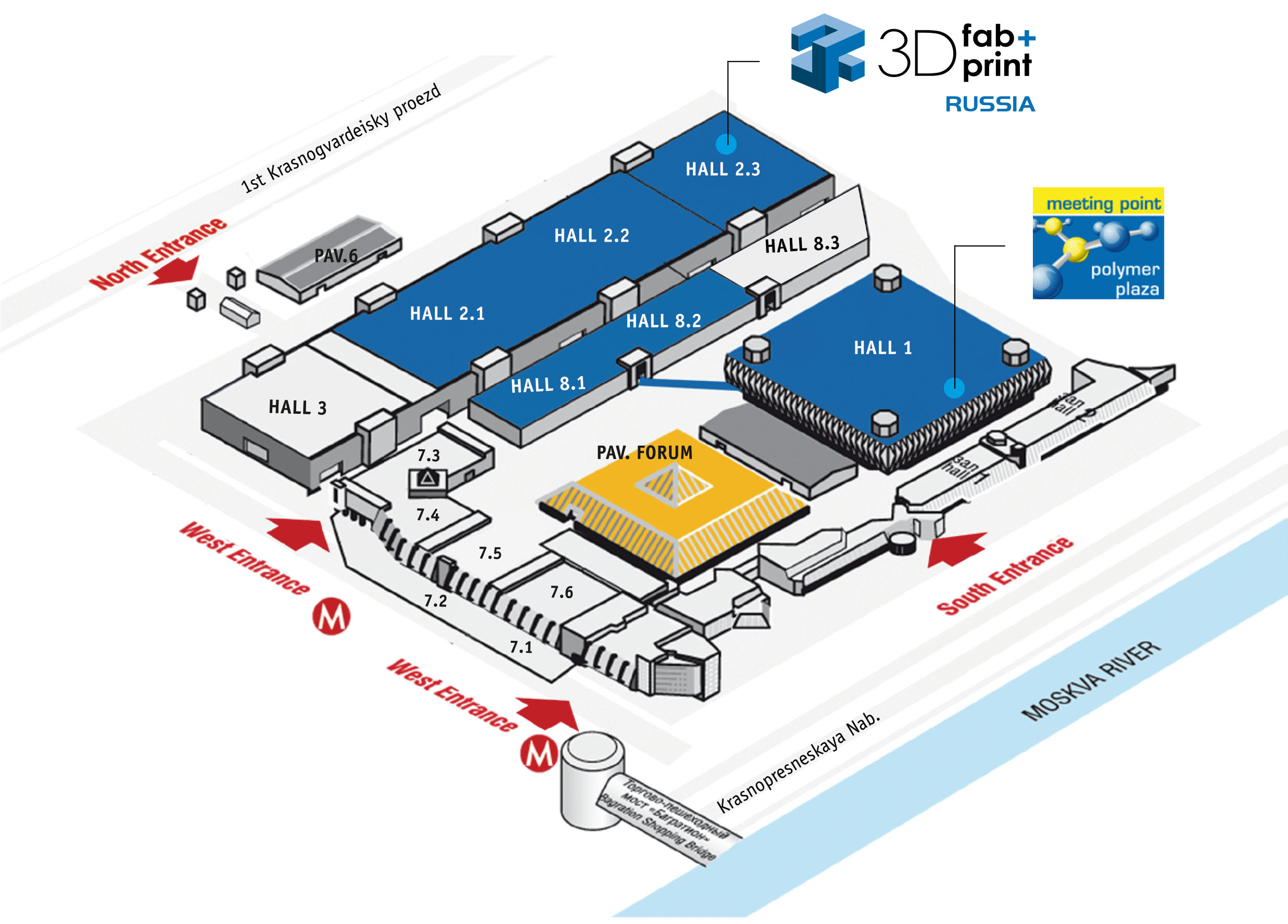

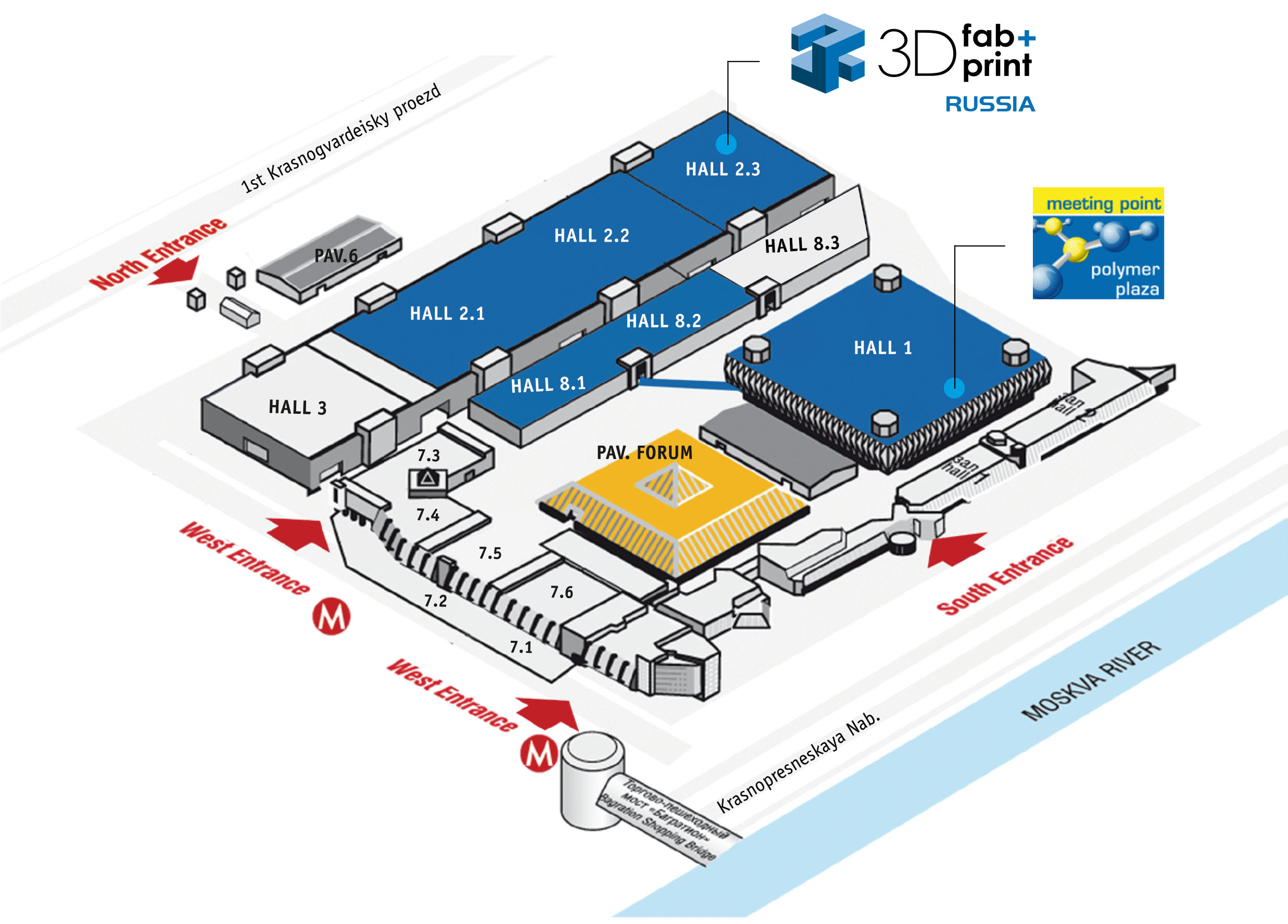

The upswing in major market segments is leading to strong demand for plastic and rubber products as well as packaging. The manufacturers of these products are investing as much as they can in modern production technologies and materials, in order to be able to satisfy the increasingly exacting requirements made by their customers. About 900 companies from 30 countries presented their innovations at the two trade fairs in the SAO Expocenter in Krasnaja Presnja from 23. to 26. In 2018, 24,900 experts from all over Russia and from the neighbouring countries visited interplastica and upakovka. 23,000 visitors were registered in 2017.

Werner M. Dornscheidt, CEO of Messe Düsseldorf GmbH, was satisfied with the trade fairs: “To the extent that the Russian economy is developing positively and reliably, Russian companies are taking advantage of the two leading industry showcases. The exhibitors that maintained a consistent presence in Russia under poorer market conditions as well are now benefitting to a particularly large extent from their good contacts in the industry. In addition to the conclusion of many sales contracts, the high quality of the demand was a very important sign that an economically attractive future is beginning.”

The improvement in the rouble exchange rate is now helping to enable Russian companies that had to defer necessary purchases in the recent crisis years to invest in the modernisation of their production.

Global exports of plastics and rubber machinery to Russia declined for a number of years. In 2016 (more recent figures are not available yet), the total value of supplies to Russia from all over the world amounted to about EUR 326 million, which was almost 43 per cent lower than in the previous year. Two of the most important sources of supply – Germany and Italy – are, however, reporting that exports increased enormously in 2017. From January to November 2017, German deliveries of plastics and rubber machinery to Russia totalled EUR 104.1 million, which represents growth of 43.5 per cent over the same period the previous year (source: VDMA plastics and rubber machinery association). The Italian manufacturers of machines, equipment and moulds for the processing of plastics and rubber delivered goods worth EUR 73 million to Russia in the first nine months of last year, which amounts to 109 per cent more than in the same period of 2016. According to AMAPLAST, the Italian industry association, this means that Russia is one of the ten most important export destinations again, following very poor years that were attributable to economic sanctions and difficult market conditions.

Thorsten Kühmann, Director of the VDMA plastics and rubber machinery association, is confident about the current situation on the Russian market: “The patience and persistence shown by the German plastics and rubber machinery manufacturers, who continued to cultivate German-Russian business relationships even in bad economic times, paid off in 2017. After years of decline, deliveries from Germany increased substantially. As a result, the poor previous year was already exceeded considerably in the first eleven months of 2017. This economic recovery is being supported by an improvement in the basic mood in the Russian economy. This is leading to greater willingness to invest, which is being reflected primarily in the packaging sector.

The Italian manufacturers of machines and equipment are also reporting an increase in the requirements made by customers in Russia and the neighbouring countries. Mario Maggiani, AMAPLAST Director: “What have been sold in recent months have primarily been high-quality extrusion lines and other core machinery with high added value, often manufactured in accordance with the customer’s specifications. Russian processors are investing not only to expand their production lines but also to increase their quality. Italian manufacturers are benefitting from this, because they have a good reputation in the country and are in a position to supply turnkey high-tech equipment that meets the most demanding of quality and productivity requirements.” Maggiani does not expect sales levels reached by Italian plastics machinery manufacturers in 2007, for example, with a total volume of more than EUR 200 million, to be matched in the foreseeable future: “That will be neither easy nor possible in the short term. Demand in the Russian plastics processing sector for mature technologies to satisfy customers’ needs for high-quality products will definitely be continuing to increase. The positive response from the market makes the Italian suppliers optimistic. They feel vindicated, since they continued to believe in the potential of the market even in difficult times and maintained a consistent presence as a result.” More than 50 companies from Italy, about 40 of which exhibited on the joint AMAPLAST stand, experienced lively demand during the trade fair and are expecting good business as they follow up the event.

Press relase published by Interplastica. Interplastica is a member of Global Gate, the brand in which Messe Düsseldorf has pooled its global activities for the plastics and rubber industry.

Original article on this link.

Werner M. Dornscheidt, CEO of Messe Düsseldorf GmbH, was satisfied with the trade fairs: “To the extent that the Russian economy is developing positively and reliably, Russian companies are taking advantage of the two leading industry showcases. The exhibitors that maintained a consistent presence in Russia under poorer market conditions as well are now benefitting to a particularly large extent from their good contacts in the industry. In addition to the conclusion of many sales contracts, the high quality of the demand was a very important sign that an economically attractive future is beginning.”

The improvement in the rouble exchange rate is now helping to enable Russian companies that had to defer necessary purchases in the recent crisis years to invest in the modernisation of their production.

Global exports of plastics and rubber machinery to Russia declined for a number of years. In 2016 (more recent figures are not available yet), the total value of supplies to Russia from all over the world amounted to about EUR 326 million, which was almost 43 per cent lower than in the previous year. Two of the most important sources of supply – Germany and Italy – are, however, reporting that exports increased enormously in 2017. From January to November 2017, German deliveries of plastics and rubber machinery to Russia totalled EUR 104.1 million, which represents growth of 43.5 per cent over the same period the previous year (source: VDMA plastics and rubber machinery association). The Italian manufacturers of machines, equipment and moulds for the processing of plastics and rubber delivered goods worth EUR 73 million to Russia in the first nine months of last year, which amounts to 109 per cent more than in the same period of 2016. According to AMAPLAST, the Italian industry association, this means that Russia is one of the ten most important export destinations again, following very poor years that were attributable to economic sanctions and difficult market conditions.

Thorsten Kühmann, Director of the VDMA plastics and rubber machinery association, is confident about the current situation on the Russian market: “The patience and persistence shown by the German plastics and rubber machinery manufacturers, who continued to cultivate German-Russian business relationships even in bad economic times, paid off in 2017. After years of decline, deliveries from Germany increased substantially. As a result, the poor previous year was already exceeded considerably in the first eleven months of 2017. This economic recovery is being supported by an improvement in the basic mood in the Russian economy. This is leading to greater willingness to invest, which is being reflected primarily in the packaging sector.

The Italian manufacturers of machines and equipment are also reporting an increase in the requirements made by customers in Russia and the neighbouring countries. Mario Maggiani, AMAPLAST Director: “What have been sold in recent months have primarily been high-quality extrusion lines and other core machinery with high added value, often manufactured in accordance with the customer’s specifications. Russian processors are investing not only to expand their production lines but also to increase their quality. Italian manufacturers are benefitting from this, because they have a good reputation in the country and are in a position to supply turnkey high-tech equipment that meets the most demanding of quality and productivity requirements.” Maggiani does not expect sales levels reached by Italian plastics machinery manufacturers in 2007, for example, with a total volume of more than EUR 200 million, to be matched in the foreseeable future: “That will be neither easy nor possible in the short term. Demand in the Russian plastics processing sector for mature technologies to satisfy customers’ needs for high-quality products will definitely be continuing to increase. The positive response from the market makes the Italian suppliers optimistic. They feel vindicated, since they continued to believe in the potential of the market even in difficult times and maintained a consistent presence as a result.” More than 50 companies from Italy, about 40 of which exhibited on the joint AMAPLAST stand, experienced lively demand during the trade fair and are expecting good business as they follow up the event.

Press relase published by Interplastica. Interplastica is a member of Global Gate, the brand in which Messe Düsseldorf has pooled its global activities for the plastics and rubber industry.

Original article on this link.

SITIOS DESTACADOS

E-News Categories

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos