Issue 160

Suscríbete

Full Shine Presents the Updated and Customized Blow Molding Machine Equipped with Robot Automation

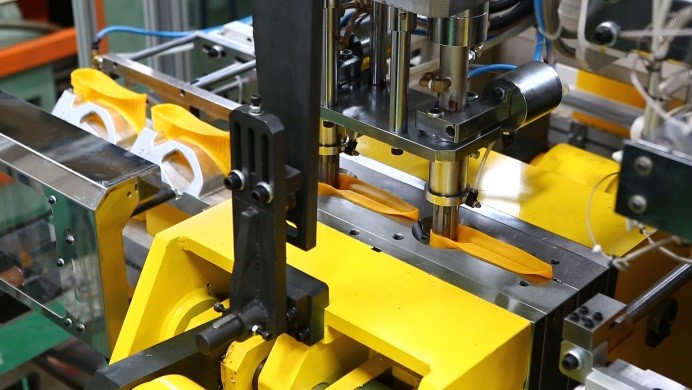

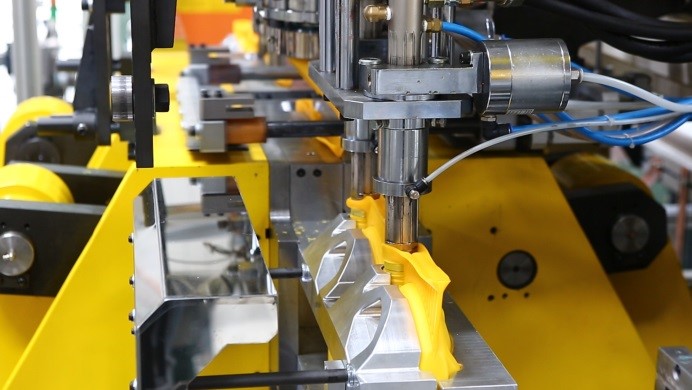

Full Shine FS-100PDDV can offer 480-515 pcs of 4L Plastic Lubrication bottle per hour by double die head and double station, which is equipped with a diameter of 100mm screw for raw material feed in and allows producing the bigger size of plastic items with high speed. Also, the screw drive in control of direct-mounted gearbox and inverter motor as energy-saving feature to reduce unnecessary cost, which can make large jerry can for oil or other shortage.

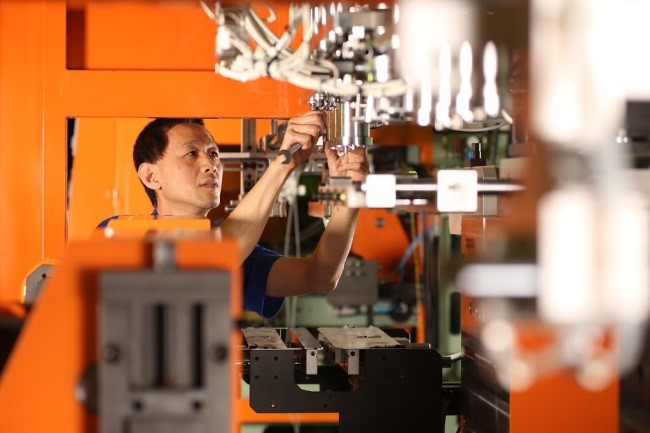

Full Shine has 27 years of experience in blow molding machine industry and always improves our worldwide customers' processes, productivity and capacity by suitable machines. Our state-of-the-art blow molding machine- FS-100PDDV with curved arms for strong mold clamping, equipped with linear slide guide way, made in Germany for swift movement, screw drive in the control of direct-mounted gear box and Inverter motor as power-saving feature, double die-head & double station & view strip device. This machinery is also with the concept of offering user-friendly design, easy operation, durability and less maintenance.

With the pursuit of high production efficiency and less labor work, FULL SHINE’s blow molding machine is capable of fast accumulation. Not only the high production, but also our feature of robot automation, which is came with auto de-flashing system, leak testing/ weight tester, auto-recycling system. Not only the central material supply system is equipped, but also Full Shine can design the inner labeling machine for customization. To achieve the target of the intensive and complete production line, therefore the labor work could be reduced hugely.

Full Shine Plastic Machinery has been fully dedicated to the development of blow molding machines so as to provide our clients with more optional turnkey solutions that can help them enhance both quality and capacity. To prospect the future, we set our sights on stable quality of present products, develop new technologies and design, expand the foreign market, and promote Full Shine machinery.

Our Products and service - Full Shine Specializes Below Machines

Full Shine keeps running principle consistently -“Think globally, footing locally, Active & Creative, Enjoys challenge, Brand Marketing, and Constant Operation”. To prospect the future, we set our sights on stable quality of present products, research and develop new technologies and design, expand the foreign market. Full Shine will keep innovation and bring a more flexible machine in the near future.

For more information, please visit our website: www.full-shine.com or please email to : [email protected]

Future Exhibition:

2019 K Trade Fair

|

|

|

|

Full Shine has 27 years of experience in blow molding machine industry and always improves our worldwide customers' processes, productivity and capacity by suitable machines. Our state-of-the-art blow molding machine- FS-100PDDV with curved arms for strong mold clamping, equipped with linear slide guide way, made in Germany for swift movement, screw drive in the control of direct-mounted gear box and Inverter motor as power-saving feature, double die-head & double station & view strip device. This machinery is also with the concept of offering user-friendly design, easy operation, durability and less maintenance.

|

|

With the pursuit of high production efficiency and less labor work, FULL SHINE’s blow molding machine is capable of fast accumulation. Not only the high production, but also our feature of robot automation, which is came with auto de-flashing system, leak testing/ weight tester, auto-recycling system. Not only the central material supply system is equipped, but also Full Shine can design the inner labeling machine for customization. To achieve the target of the intensive and complete production line, therefore the labor work could be reduced hugely.

|

|

Full Shine Plastic Machinery has been fully dedicated to the development of blow molding machines so as to provide our clients with more optional turnkey solutions that can help them enhance both quality and capacity. To prospect the future, we set our sights on stable quality of present products, develop new technologies and design, expand the foreign market, and promote Full Shine machinery.

Our Products and service - Full Shine Specializes Below Machines

- Automatic Blow Molding Machine

- Automatic Accumulative Blow Molding Machine

- Automatic Co-extrusion Blow Molding Machine

- One Stage Injection Blow Molding Machine

- One Stage PET Injection Stretch Blow Molding Machine

- Automatic and Semi-auto PET Stretch Blow Molding Machine

- Integrate machines production in automation

- Die head, Mold and optional equipment

Full Shine keeps running principle consistently -“Think globally, footing locally, Active & Creative, Enjoys challenge, Brand Marketing, and Constant Operation”. To prospect the future, we set our sights on stable quality of present products, research and develop new technologies and design, expand the foreign market. Full Shine will keep innovation and bring a more flexible machine in the near future.

For more information, please visit our website: www.full-shine.com or please email to : [email protected]

|

|

Future Exhibition:

2019 K Trade Fair

- Date:10/16 (Wed.) – 10/23 (Wed.), 2019

- Venue:Messe Düsseldorf, Stockumer Höfe

- Booth:Hall 3, C30

|

| Official Website https://www.full-shine.com/en/index.html Full Shine in PRM-TAIWAN https://www.prm-taiwan.com/com/full-shine.htm |

SITIOS DESTACADOS

E-News Categories

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos