POLYSTAR: Does your Factory have the Right Solution for Recycling your Materials?

Producers understand the relevance of recycling the plastic waste created by their facilities. The shortage of resins drove plastic producers to respond faster and take action to recycle their factory waste, and thus to explore innovative ways to recycle post-consumer waste.

Recycling with easy operation and maintenance

Plastic materials such as polyethylene and polypropylene are produced and reproduced in the plastic industry. Producers are striving for a complete circular economy process in order to save money and protect the environment.

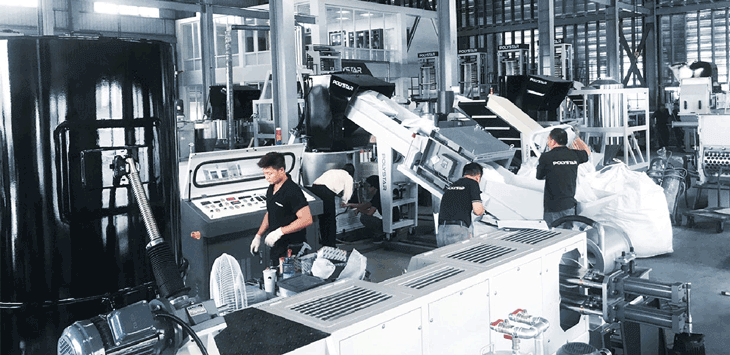

POLYSTAR has been working directly with manufacturers to combine their ideas and requirements with recycling machine design and reengineering to improve overall equipment effectiveness, product quality, and operator control.

Three recycling machines for different plastic materials

As a manufacturer of recycling machines, we must keep in mind that recycling demands more than just a machine. It's critical to have a plastic recycling machine that runs smoothly and produces high-quality products. Producers can choose from a variety of recycling options provided by POLYSTAR. Here are some suggestions to ensure that your recycling process meets your needs and requirements.

- For factory film waste

Recycling your industrial trash can help you save money on production. The reusability of your pellets will be 100% if your material is 100% from your production, allowing you to reuse them in your factory line.

POLYSTAR's Repro-Flex plastic recycling machine is designed to recycle PE (HDPE, LDPE, LLDPE) and PP flexible packaging waste.

(Repro-Flex Plastic Recycling Machine)

This machine has a cutter-compactor, which eliminates the requirement for material pre-cutting. The system uses centrifugal force to feed the material directly into the extruder, ensuring that it is in the best possible condition for extrusion.

Want to know more about this product: Customer Stories - Japanese recycler increases efficiency and production in pelletizing

- For factory raffia waste

Due to the strength and mechanical qualities of the materials, recycling PP raffia, woven sacks, tapes, non-woven/woven, and bulk bags in one step may be difficult for some producers.

The versatility of POLYSTAR's Repro-One shredder integrated recycling machine allows raffia and non-woven/woven bag producers to quickly reprocess their factory production waste in just one step.

(Repro-One Shredder Integrated Recycling Machine)

A heavy-duty single-shaft shredder is included in this equipment and is immediately connected to the extruder and pelletizing system. Tapes, fabric, giant bags, lumps, and other PP trash can all be pelletized with this equipment. Recycling pellets can be simply reintroduced into tape extrusion processes.

Want to know more about this product: Successful Story- Shredder Integrated Plastic Recycling Machine

- For multilayer film and post-consumer waste

Multilayer films, heavily printed plastic waste, post-consumer plastic trash, and BOPP films can be recycled; however, reprocessing them is complex. Most of the time, the recycled pellets made from these materials are of poor quality.

The two-stage recycling machine Repro-Flex Plus from POLYSTAR satisfies your needs if you're searching for little material degradation.

( Repro-Flex Plus Two-stage Recycling Machine)

It can reprocess post-consumer plastic waste and highly printed material, and thanks to the integration of the cutter compactor and systems like the two filtrations and three degassing units, your recycled pellets will be of the highest quality and productivity.

Want to know more about this product: Two-stage Plastic Recycling Machine

Lower your costs. Maintain the quality of your products.

Producers are looking for solutions to their needs due to a shortage of resins and new trends of utilizing more recycled materials. POLYSTAR provides your factory with exceptional design in your plastic recycling equipment. Providing you with the highest quality recycled pellets, easier machine control, and lower production costs.

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos