PP Tray Washing Line for High-Value Application by BoReTech Achieves Efficient Performance

Nextek said that the UK consumes 210,000 tons of food-grade PP per year. In comparison, China generates an average of about 1.5 million tons of plastic tray waste annually. There are 250,000 tons of waste disposable lunch boxes to be recycled, accounting for only 1% of all plastic waste that is recycled. Compared with the mature technology and experience of PET bottle recycling, there are still common technical difficulties in large-scale PP lunch box recycling applications. Currently, the recycling rate of PP lunch boxes worldwide is generally low, and there is a potential market.

In 2021, BoReTech provided a 2000 kg/h PP tray washing line for local customer RE-MALL. The PP recycling line has been successfully operating for half a year, producing high-quality recycled PP pellets, helping RE-MALL take “purer, more stable, more environmentally friendly and safer” as the product concept, and practice the mission of promoting plastic recycling through technology and innovation to protect and purify our environment.

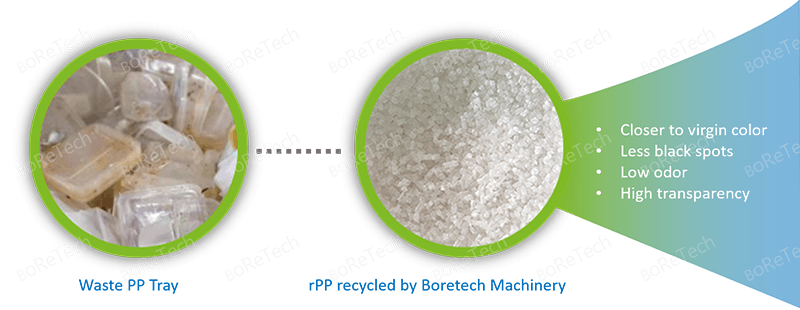

Relying on the R&D advantages and production experience of BoReTech, and the customer’s professional polymer background support, this project solved the PP hot washing problem of suspension, removed the rPP odor, and reduced the PP fines during the production to enhance the PP yield rate. The recycled PP quality from this system is positioned as a high-value application with high-quality characteristics, fewer black spots, lower odor, and high transparency. It has been used in high-end application markets such as daily chemical packaging, auto parts, and non-woven fabrics to enhance the market competitiveness for the customer.

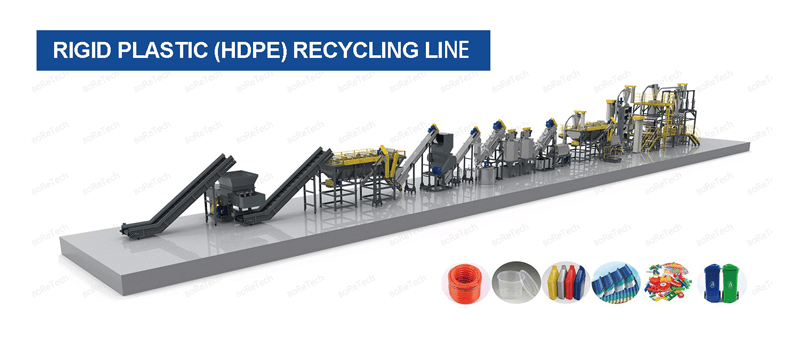

Since 2021, BoReTech has provided the total recycling solution and machinery for rigid plastic and film plastic to the market, and one project of HDPE recycling system has completed the delivery to the Indian market, which customers have accepted well. The Polish project of HDPE bottle recycling has also completed the shipment and is waiting for installation and commissioning.

More than 30 years of experience in R&D, design, operation, and manufacturing of PET bottle recycling equipment have helped BoReTech quickly enter the market of hard plastic and film recycling equipment.

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos