FULL SHINE: Multi-Layer Plastic Bottle, Extrusion Blow Molding Machine or Injection Blow Molding Machine?

In current plastic bottle making industry, extrusion blow molding machine and one stage injection blow molding machine are two most commonly used technology to produce different type of bottles

1. Extrusion blow molding machine:

It is the most commonly used machine to make plastic bottles. Raw material dropped from an extruder into a water cooled mold and get blown into the final product directly.

The pros & cons are as below:

Pros:

1. Cheaper in mold, die mouth… etc. tooling cost

2. Larger variety of bottles production from 1ml-3000L

3. Higher production efficiency and higher degree of automation

4. Can produce Multi-Layer bottles/ products

5. Suitable to produce PE.PP.PVC. and TPU… etc. material bottles

6. With full turnkey solution setup, the wasted material can be 100% fully reused to be more environmentally friendly

Cons:

1. Limited shape in product design

2. Difficulty in controlling wall thickness

3. Lower degree in product precision

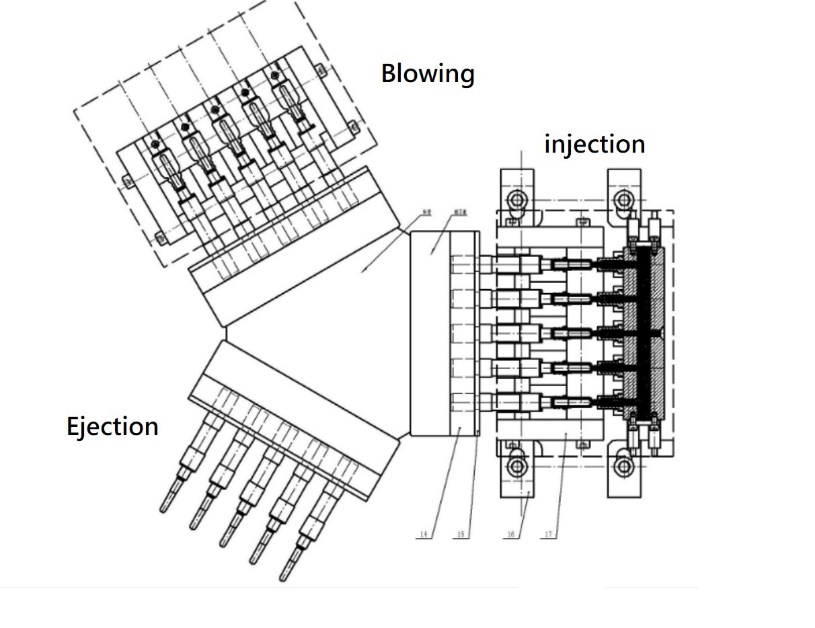

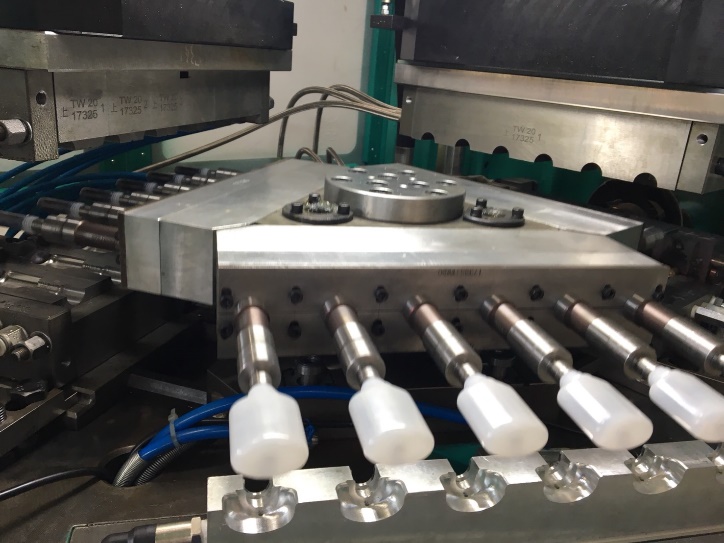

2. One Stage Injection Blow Molding Machine:

It is the combination technology of Extrusion blow molding machine and Injection molding machine. Raw Material is firstly injected as preform shape in the first sector, then get blown into bottle shaped final product.

The pros & cons are as below:

Pros:

1. higher degree in product precision especially in neck part

2. No bottle body parting line

3. Higher production efficiency and higher degree of automation

4. Better wall thickness distribution and higher bottle bottom intensity

5. Suitable to produce small delicate and jar bottle like eye drop and glue bottles

Cons:

1. Limited volume in product, normally in between 5-1000ml

2. Limited bottle shape design

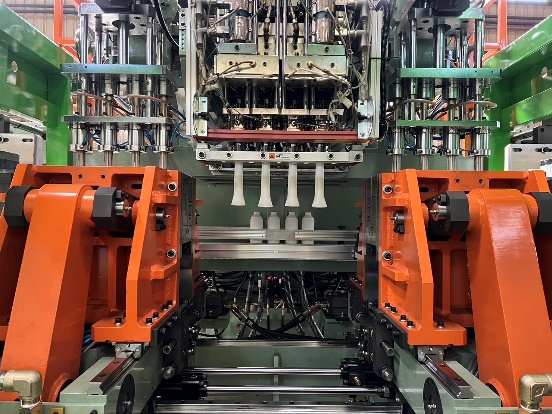

3. Extrusion blow molding machine & One Stage Injection Blow Molding Machine Actual Product Application comparison:

Take 250ml Milk bottle sold in retail store for example, we can find out that there are line marks on the bottle bottom, and relatively worse thickness distribution, and lower bottle strength from those made by Extrusion blow molding machine.

However, for those made by One stage injection blow molding machine, those are more flat in bottom, equally body thickness, accurate neck dimension, less shrinkage and better for cap sealing. However, despite many pros, by One stage injection blow molding machine is not suitable to make handled bottle.

As a result, the two machines both have their pros and cons, and to find your best match machine, feel free to contact Full Shine Plastic Machinery in Taiwan.

4. Multi-Layer Bottle Application:

The below machine is Full Shine’s latest Model FS-75PFDDV. This energy-saving machine is designed as Four Head + Two Station + Two Layer + View Stripe setup for 2 Layer 1L handled Agro Bottle production with approx. 1200 Bottles hourly production rate. The machine enables the customer to use only 20% Raw Material with the rest 80% to be recycled material so as to not only save huge amount of material cost but also more environmentally-friendly and can save approx. 30-60% energy consumption with the energy-saving system.

Choose Full Shine Plastic Machinery to process any your plastic products.

Full Shine Machinery has 30 years of experience specializing in Automatic Blow Molding Machines, Multi-layer Co-extrusion Blow Molding Machines (2-6 layers bottle), Accumulator-head Blow Molding Machines, One Stage Injection Blow Molding Machines, and PET Stretch Blow Molding Machines. In addition, we have experience with Molds, Die Heads, and Auxiliary Equipment. Please contact us to learn more about our capabilities.

If you want to know more about our other products, please check the link below.

https://www.full-shine.com/en/products.html

To keep updated about the latest news of Full Shine Machinery, please follow us in our Social Media Channels:

● Full Shine YouTube Channel

https://www.youtube.com/channel/UCEqOofSPN-0nljuc8WyG-uQ

● Full Shine Facebook Channel

https://www.facebook.com/profile.php?id=100063888591844&pnref=lhc

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos