Cost-Saving and Friendly Operation POLYSTAR Plastic Recycling Machines

Plastic pelletizers are not only used by recyclers anymore as more producers now adopt circular economy standards in their factories. Having a recycling machine in your production facility not only helps the environment but can also help you cut costs, but before choosing a recycling machine you must make sure that this work well according to your needs.

In this blog, we will explain some important factors to keep in mind before choosing a plastic pelletizer.

Which details should you pay attention to when choosing a recycling machine?

Buying a machine is a tough decision with many details playing an important role. When comparing options or choosing a supplier it is easy to just look at the machine price as the main decision-making factor. Nevertheless, many underlying factors should also be considered when choosing a supplier.

Next, we introduce some of the key factors you should look closely at before deciding which recycling machine to buy:

1. Components

( CRYDOM and Schneider Electric components used in POLYSTAR´s machines )

When using machinery, it is critical to think of time as a resource, the amount of time the machine runs will determine the output you can obtain. In such a scenario, choosing a recycling machine with reliable components is critical, as low-quality components can lead to recurrent fuses burnt and increased machine downtime, reducing profits.

POLYSTAR uses world-class components such as SIEMENS, Fuji, Schneider, CRYDOM, Dynisco, and Omron to ensure a smooth operation with reliable performance.

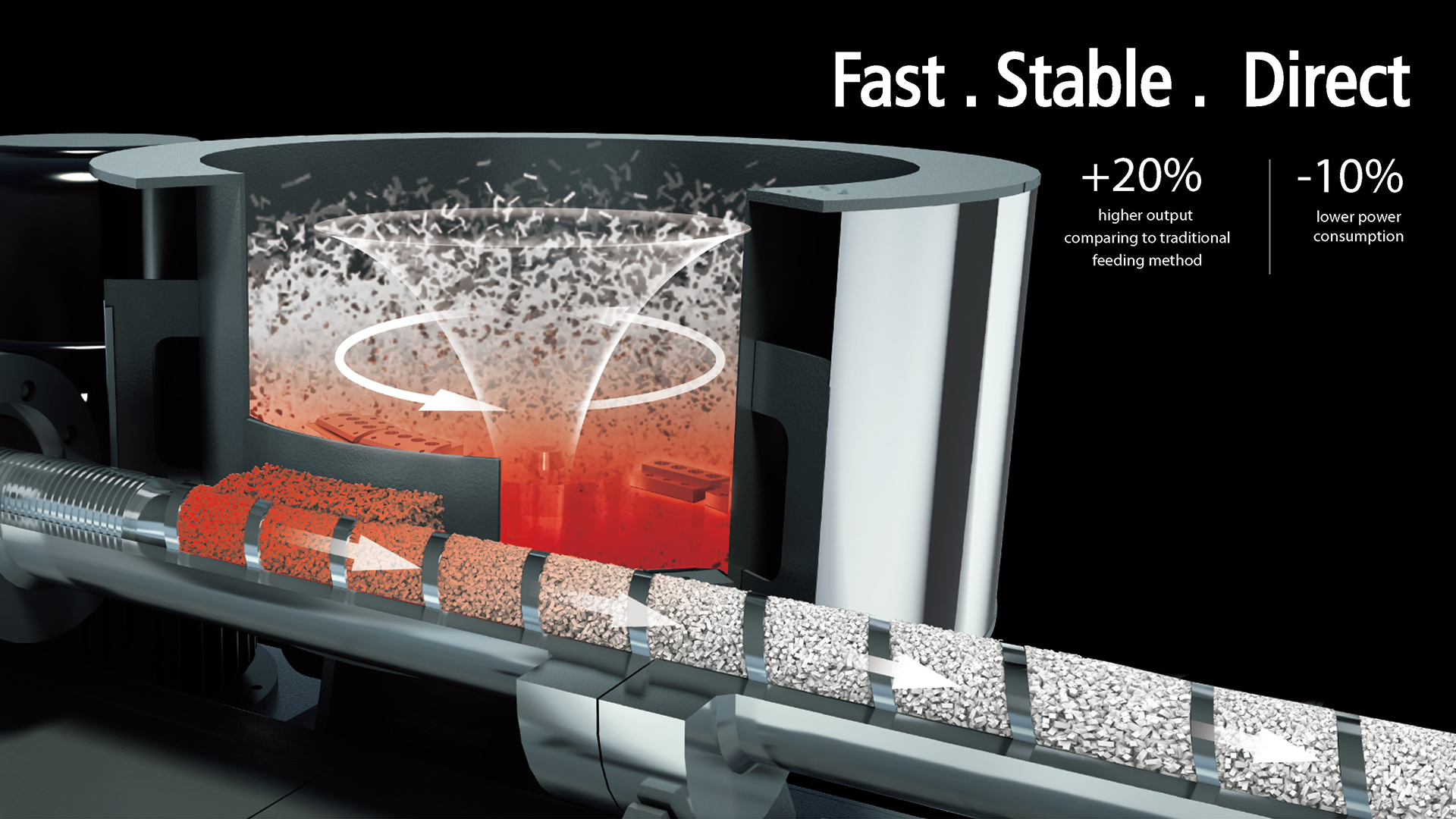

2. Energy consumption

( Cutter compactor inverter in POLYSTAR recycling machine )

The quality of the motors, components, and machine design will also determine how energy efficient the machine is.

With the inclusion of a reliable motor such as SIEMENS and inverter controls like Fuji Electric, recycling machines can ensure a stable performance while saving energy which translates into a more competitive operation.

- Indonesia - Recycling for leading PE/PP plastic bag producers - Customer Story

3. Spare parts

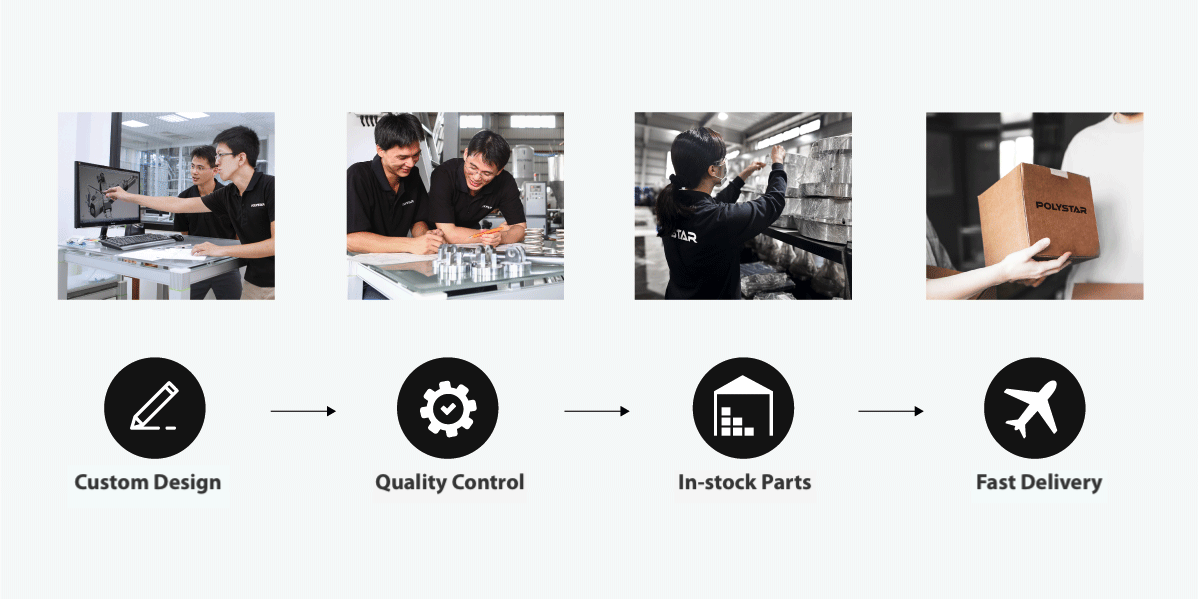

( In-stock spare parts available for POLYSTAR recycling machines )

Producers know that machine maintenance is key when running a machine for a continuous period, being able to order consumable spare parts from your original manufacturer is crucial to ensure the machine runs as smoothly as it should. In other cases, the lead times for a simple part could take months or not even be available, as many manufacturers do not sell the spare parts needed to keep the machine running for years, making the original investment useless, as when one part breaks down there is no way to repair the machine.

At POLYSTAR we have a specialized spare parts team with an easy ordering system. We provide replacements for all parts at reasonable prices, offer different shipping methods, and keep critical parts in stock in order to send out orders in as short as 5 days to help you keep your operation running.

( POLYSTAR's spare parts service helps avoid machine down time )

4. Friendly Operation

Operators are the true end users of the machinery you invest in. Ensuring the controls and machine design are intuitive and easy to use is key when evaluating a machine, remember that the operators are the ones who deal with the machine day to day, that’s why having an operator-friendly design can help you increase your profit even more by reducing errors and optimizing the operations.

( POLYSTAR pelletizer operates with low labor intervention using automatic feeding )

POLYSTAR provides flexibility in the machine design, allowing different machine layouts according to what best suits your space. Additionally, we adapt our machine controls to be displayed in English, Spanish, Turkish, Japanese, Thai, Vietnamese, Russian, etc.

- Fast machine delivery and simple installation - a clear advantage for South African customers - Customer Story

Conclusion:

The components, energy consumption, spare parts, and operation of the machine are key factors to take into consideration when evaluating a machine for investment.

If you want more information about our plastic recycling machines, feel free to contact us for more details!

Learn more

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos