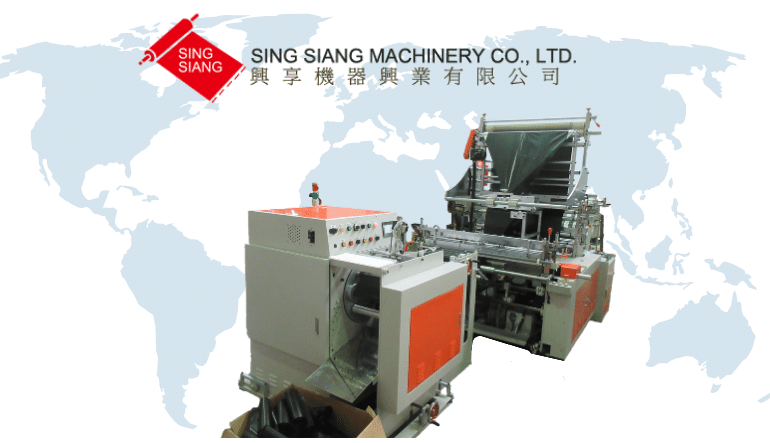

SING SIANG: Garbage Bag On Roll Machine

Sing Siang Machinery Co., Ltd. (SSM) is established in 1975 in Taiwan, specialized in all kinds of bag making machines, and always provides customers with the most comprehensive technological service. Based on more than 30 years of design and manufacturing experience, SSM is capable of designing machines with practical performance for the customer, at a reasonable and competitive price.

Each SSM machine is subject to rigorous quality inspection and performance tests before shipment to ensure the best possible performance. SSM is a symbol of dependable quality.

Our company has strong technological background and operational processing experience to maintain strict quality control on all bag making machines to meet customer expectations. For instance, our double folding trash bag on roll making machine is a specialized piece of equipment used in the manufacturing of trash bags. This machine is designed to efficiently produce trash bags that are double-folded and rolled onto a convenient spool or roll for easy dispensing.

The machine typically consists of several components and processes that work together to produce the final product. Here is a general overview of how a double folding trash bag on roll making machine operates:

1. Film Feeding: The machine starts by feeding a roll of plastic film into the system. The film is usually made of high-density polyethylene (HDPE) or low-density polyethylene (LDPE), which are commonly used materials for trash bags.

2. Bag Formation: The film passes through a series of rollers and guides, which shape and fold into a tube. Heat sealing mechanisms are used to seal the edges of the film together, creating a continuous tube.

3. Double Folding: The continuous tube of film then goes through a double folding mechanism. This process folds the tube in half lengthwise, resulting in a double-layered film with a crease in the middle.

4. Perforation and Cutting: After the double folding, the machine applies perforations along the folded film at regular intervals. These perforations allow for easy separation of individual trash bags once the roll is complete. Simultaneously, the machine cuts the folded film to the desired bag length.

5. Bag Stacking and Rolling: The cut and perforated bags are then stacked one on top of another to form a roll. The machine winds the stacked bags onto a core or spool, creating a roll of double-folded trash bags.

6. Roll Sealing and Packaging: Once the roll is complete, the machine seals the edge of the roll to secure the bags in place. Depending on the specific machine and manufacturer, the rolls may be wrapped or packaged in various ways for storage and distribution.

It's important to note that different manufacturers may have variations in their machine designs and processes. The above steps provide a general overview of how a double folding trash bag on roll making machine typically operates.

Supported by all our customers worldwide, we have the chance to innovate our product to meet advanced standards, and we have won a good reputation in the bag-making area. To meet the challenge of ever-changing market conditions and uplift production efficiency, we have invested greatly in technological development and innovation, and emphasis on the training of our employees. All the machine making process is rigidly supervised to make perfect quality and advanced equipment.

In addition, our bag making machine has developed humanized and automatic operating functions in pursuit of good quality and high efficiency. Through a central control system with a human-machine interface touch screen and PLC control, plus automatic alarm system, operators can accurately and simply control the bag making machine quality.

In the Future, we will improve our technology to be more efficient, user–friendly, and durable to stay competitive in the market from constant customer feedback and information. If you have any questions, please do not hesitate to contact us.

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos