Revolutionizing the Market: Chyi Yang's Smart 5/7-layer Blown Film Machines Lead the ESG Sustainability Trend

Multilayer co-extrusion high-speed blown film machines are now the mainstream equipment in plastic film production. They are versatile and widely used in packaging, agriculture, construction, and more. With the rise of the circular economy trend, recycling waste materials can reduce production costs, minimize material waste, and offer numerous benefits. It also reduces the demand for virgin materials and aligns with increasingly strict regulations. There are two main methods: mechanical shredding recycling and physical property recycling. Mechanical shredding involves using additional equipment to reuse production trimmings, while physical property recycling processes waste films in specialized facilities. While 90% of the market prefers mechanical shredding for cost efficiency, challenges exist in controlling waste weight and additive ratios.

Breaking Market Bottlenecks: Chyi Yang's Recycling Innovation

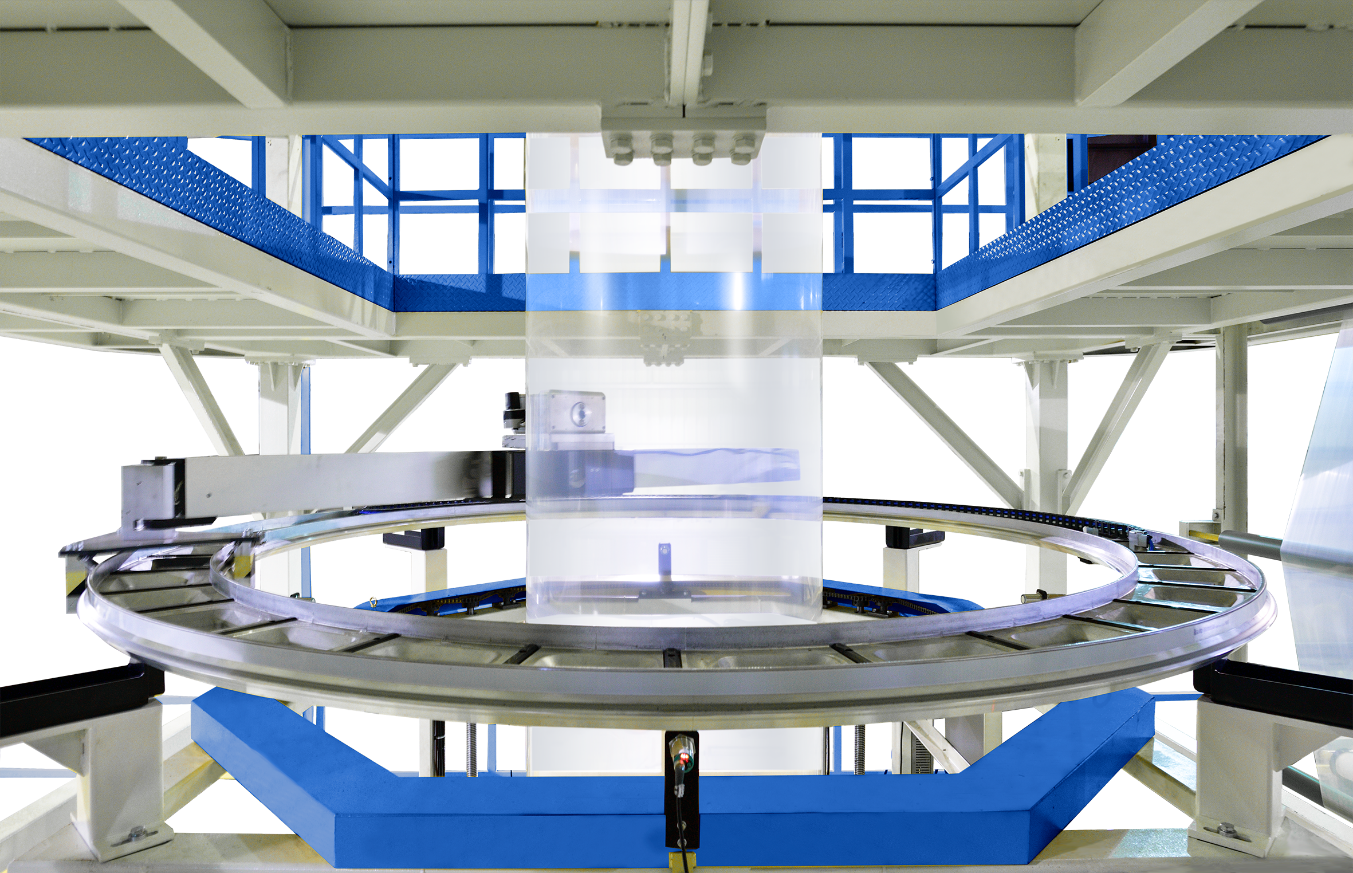

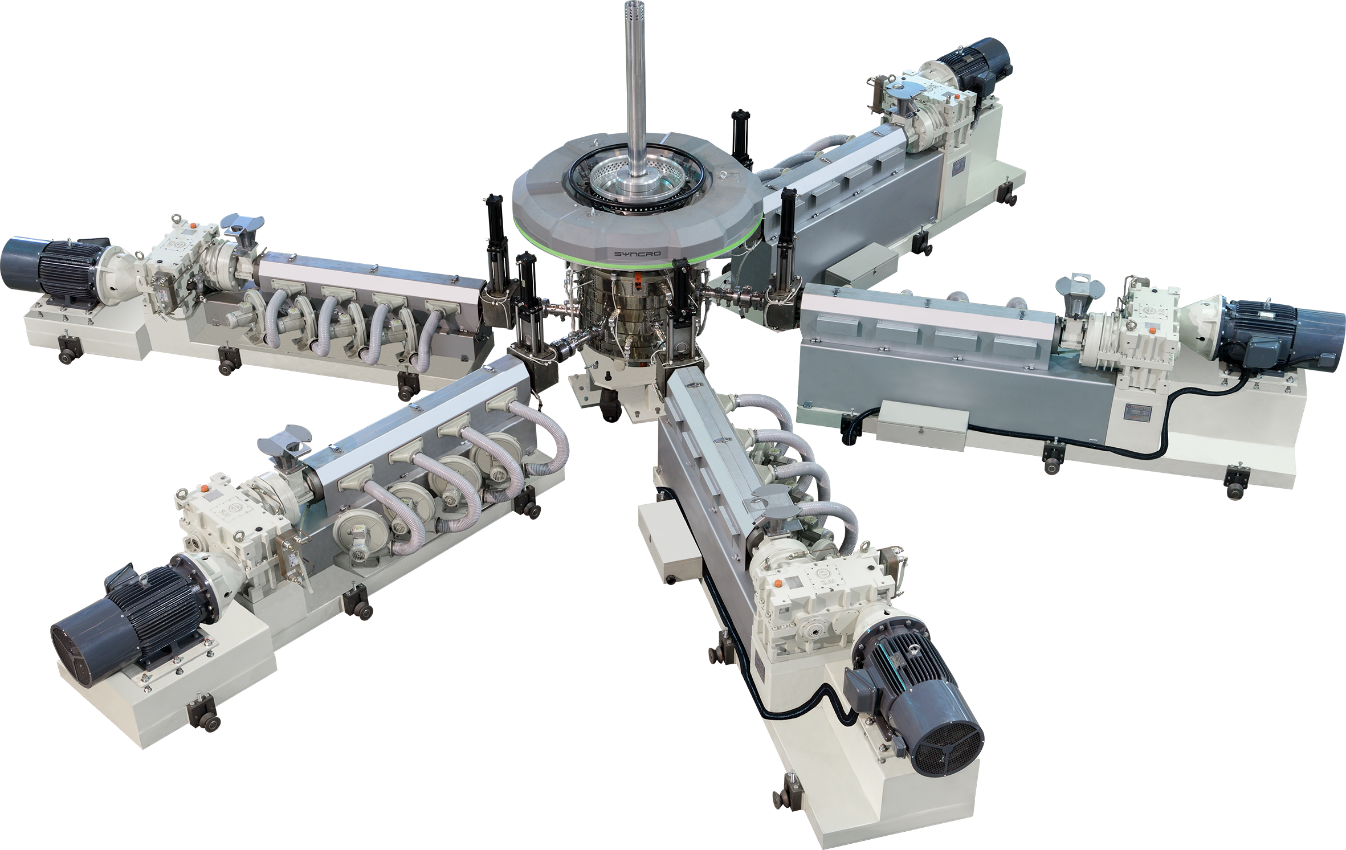

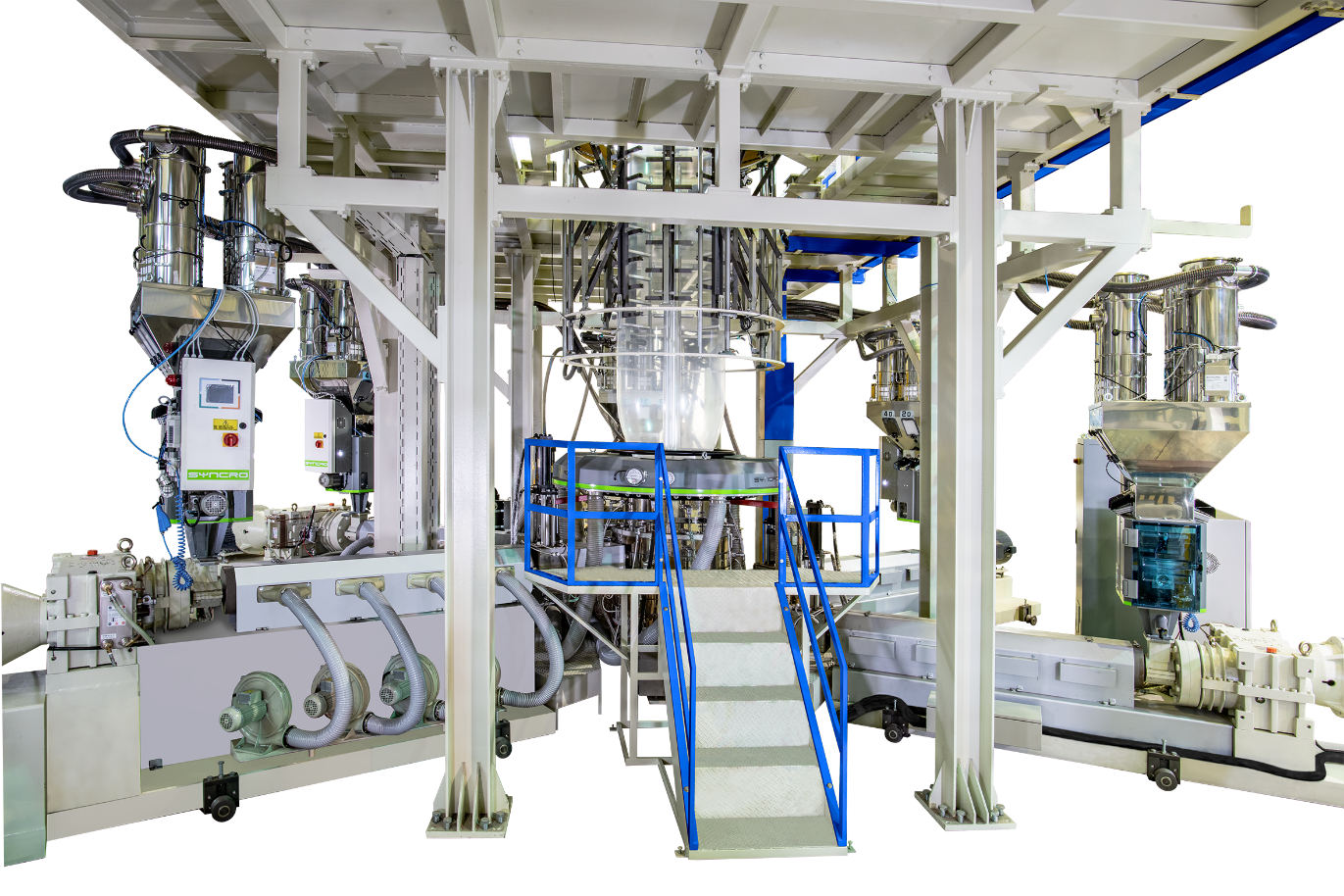

In the current global trend of increasing environmental awareness and the demand for efficient recycling of waste materials, Chyi Yang Industrial Co., Ltd., a leading company in the blown film equipment industry, has developed advanced recycling mechanisms for their multilayer blown film machines. Their latest innovation, the 5-Layer / 7-Layer Co-Extrusion Blown Film Machine, not only introduces "big data-driven precision formula calculations" but also "revolutionizes waste material recycling techniques", making a significant impact on the blown film production market.

Chyi Yang's co-extrusion high-speed blown film machines, equipped with intelligent monitoring and precision formula calculation capabilities, can automatically feed materials, detect material sufficiency, and it also can provide real-time reminders and replenishment based on pre-set configurations. By leveraging the real-time data provided by the equipment, production parameters can be adjusted promptly according to the process conditions. This automated control enables the adjustment of various material proportions and additives, reducing downtime and minimizing the impact of manual operations on the formula. As a result, the yield is highly improved.

Chyi Yang, a leading manufacturer of film recycling equipment, introduces advanced automatic edge trimming and pelletizing recycling capabilities in their blown film machines. This innovative approach replaces the conventional method of shredding film for recycling. During the production process, the waste material is directly absorbed into the innermost layer of the machine: it undergoes heating, extrusion through a small screw, pellet cutting, air cooling, and pelletizing, all within an automated system.

This automated recycling process resolves the challenge of accurately weighing film fragments, allowing manufacturers to estimate the proportion of recycled materials consumed. While operating continuously for 24 hours without downtime, manufacturers can set precise formula ratios, aiming for "ZERO WASTE" in the production process and embracing the principles of the circular economy. Chyi Yang's commitment to environmental recycling trends has positioned them as the most favored manufacturer of blown film equipment in the market.

Green Circular Ecosystem: Auto-Recycling Blown Film Machines Lead the Way

The development of advanced recycling efficiency and quality is essential for 5-layer/7-layer co-extrusion high-speed blown film machines to meet the challenges of ESG and environmental sustainability. Producers need to leverage intelligent technologies to reduce energy consumption and carbon footprint, enhance productivity and data management, lower costs and waste, and improve competitiveness. In the future, materials and formulations used in blown film machines will be more environmentally friendly, multifunctional, and high-performance, enabling more efficient, energy-saving, and resource-efficient production processes. This will further contribute to the goals of environmental protection and sustainable development.

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos