JING DAY: The Strategic Role of Rubber Military Supplies in Modern Warfare

Rubber has long been a crucial material in various industries, and its significance extends to the military domain. From tires to protective gear, rubber plays a pivotal role in enhancing the effectiveness and survivability of armed forces around the world. In this article, we will explore the diverse applications of rubber military supplies and their strategic importance in modern warfare.

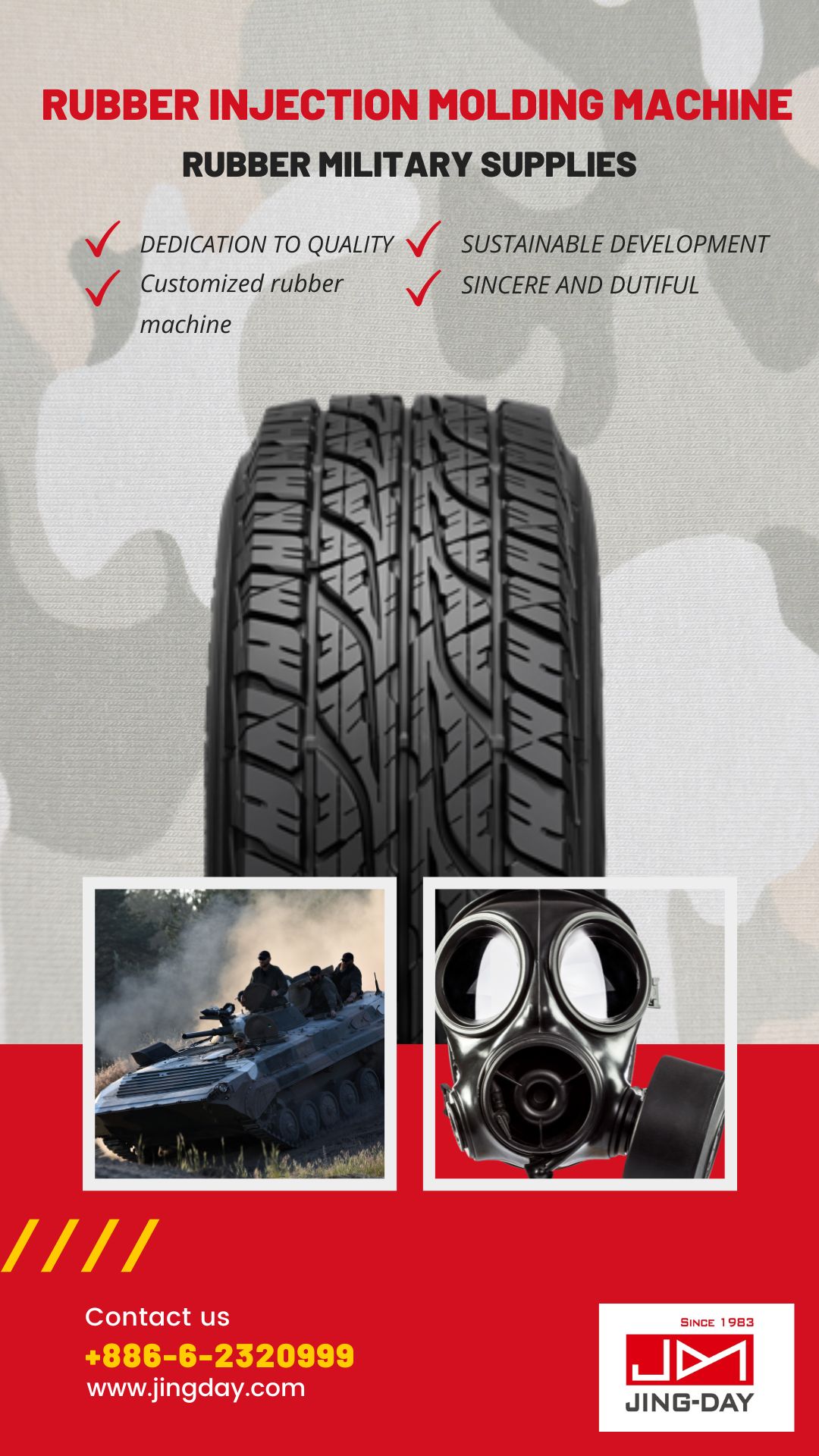

1.Tactical Tires:

One of the primary applications of rubber in the military is in the manufacturing of tactical tires. Military vehicles heavily rely on robust and durable tires to navigate diverse terrains, from deserts to jungles. High-quality rubber compounds ensure optimal traction, durability, and resistance to punctures, enabling military vehicles to perform under challenging conditions.

2.Protective Gear:

Rubber is a key component in the production of various military protective gear, including boots, gloves, and specialized clothing. These items provide soldiers with essential protection against environmental hazards, chemical agents, and biological threats. The flexibility and impermeability of rubber make it an ideal material for creating gear that safeguards soldiers during different operational scenarios.

3.Aircraft Components:

Rubber is also extensively used in the aerospace industry, particularly in military aircraft. Seals, gaskets, and other components made from specialized rubber compounds ensure airtight and watertight seals, contributing to the overall performance and safety of military aircraft.

4.Amphibious Operations:

Rubber inflatables, such as boats and rafts, are crucial for amphibious operations. Specialized rubber materials provide these vessels with flexibility, buoyancy, and resistance to harsh marine environments. Rubber-based amphibious equipment facilitates covert and efficient naval operations, allowing military forces to project power across both land and sea.

5.Communication Equipment:

Rubber is a common material in the production of military communication equipment. The shock-absorbing properties of rubber help protect sensitive electronic components from damage during transportation and field deployment. This ensures that communication systems remain operational even in challenging combat environments.

6.Explosive Devices:

Rubber components are also utilized in the design of explosive devices, such as shock absorbers and blast mitigation systems. These rubber-based technologies help minimize the impact of explosions, protecting both military personnel and equipment from the destructive force of blasts.

In the realm of modern warfare, rubber military supplies serve as integral components that contribute to the success and safety of military operations. Whether in the form of tactical tires, protective gear, aircraft components, amphibious equipment, or communication devices, the versatile properties of rubber make it an indispensable material on the battlefield. As technology continues to advance, the strategic importance of rubber in military applications is likely to evolve, further enhancing the capabilities of armed forces around the world.

Learn More

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos