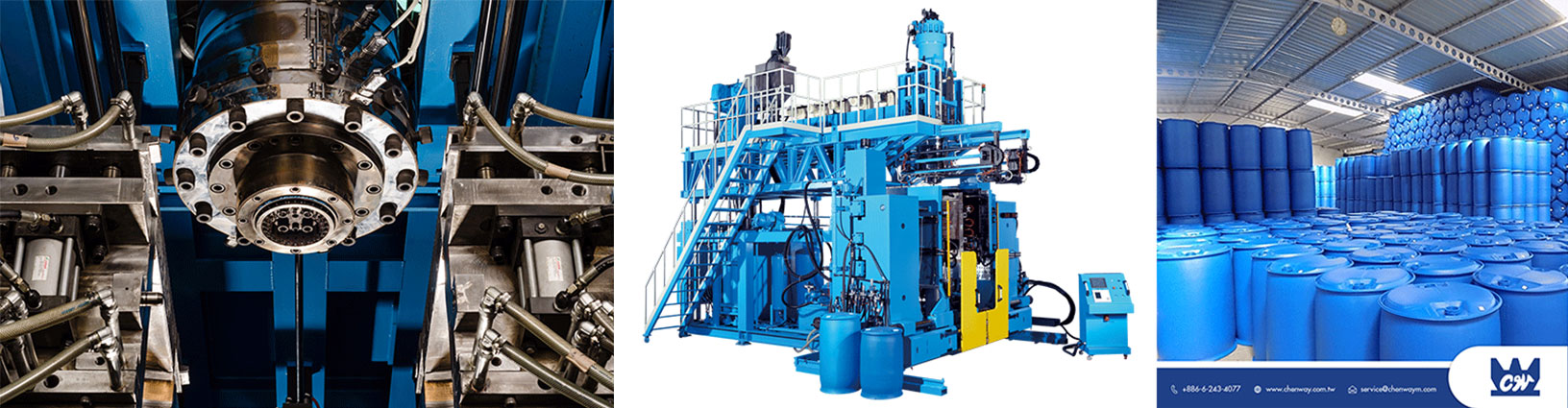

Plastic Drums and Plastic Drum Machines: A Quick Guide

Blue HDPE plastic drums are very common containers in warehouses and transport facilities across the world. These sturdy and durable containers are not only cost-effective but also incredibly useful when it comes to the safe and secure storage and transport of many different industrial goods. Given their popularity, plastic drum-making machines are also in constant demand by customers who seek effective solutions for their industrial businesses.

What are plastic drums used for?

Plastic drums are widely known for their versatility, such as being able to be easily moved around and stacked in warehouses and safely containing and transporting a wide variety of products. Some of the most common substances stored inside them include the following:

- Solvents

- Chemicals

- Pharmaceuticals

- Oils

- Lubricants

- Liquids

- Grains

- Hazardous waste

Open-head and Closed-head Drums

Plastic drum-making machines can produce HDPE drums according to clients’ requirements. These come in a variety of sizes, commonly between 50 liters up to 250 liters. Two types of plastic HDPE drums are:

- Open-top drums, which are characterized by having a top lid that can be completely removed. They are therefore typically used for both liquids and solids in situations where people need access to the contents, either for frequent addition or extraction.

- Closed-head drums, which do not have a lid and are therefore completely sealed. However, they do have two designated openings (which are sealed with secure stoppers) used to funnel liquids in or out. Due to limited access to the contents, this kind of drum is commonly used for liquids.

Plastic drums with a high volume usually have a double L-ring design which makes them stronger and even more impact resistant.

What are plastic drum machines?

Plastic drum machines are accumulator-type blow molding machines in which the plastic melt does not flow through the extrusion head continuously. Instead, the plastic is collected in a chamber or “die head” as the extruder runs for a designated amount of time. Then, the melt is released once in the product cycle. Such a process is ideal for large blow molded parts because of the required parison length.

Plastic drum machine manufacturer in Taiwan

With around 30 years of experience in the field, Chen Way Machinery is a specialized manufacturer of accumulator-type blow molding machines. We manufacture high-quality machines that can produce both open-head and closed-head HDPE drums. Customers trust our HDPE drum machines and continue to solve their packaging and logistic problems through them, an accomplishment we feel very proud of.

Double L-ring plastic drum machines

As our customers' production demands become higher, we are also challenged to step up our machines' designs and production cycle times without compromising our so renowned efficiency and good quality. Thanks to our team of well-trained engineers and technicians, we have managed to achieve this goal in many of our most recently manufactured Blow Molding machines, thus, improving their overall performance.

One example is our latest 210L to 250L range L Ring Drum making machine, for which we have achieved a faster injection speed and mold close-open movement, therefore, reducing the cycle time by 5 to 6 seconds. Furthermore, our clients can also increase their production output and fulfill their enlarged demands by adding our post-cooling unit specially designed for the narrow mouth 200L to 250L double L-ring HDPE drum, due to its high cooling capacity that helps form the plastic drum faster, thus, completing its production and saving the time.

Chen Way Machinery: running Double L ring plastic drum machine

Contact Us

In order to request further information or obtain a quotation of our blow molding machines, send us an inquiry!

You can also stay updated about Chen Way Machinery’s news, machine videos, and more through our different social media channels:

Máquina Sopladora

- Máquina automática de moldeo por soplado

- Maquinaria de moldeo por soplado

- Máquinas de moldeo por soplado de extrusión continua

- Máquina de extrusión y soplado

- Extrusora Sopladora De Plastico

- Máquina de moldeo por soplado totalmente eléctrica

- Máquinas de moldeo por soplado hidráulico

- Máquina de moldeo por soplado de plástico

Extrusora de Plástico

- Línea de extrusión de película de burbujas de aire

- Línea de extrusión de película de burbujas de aire

- Línea de coextrusión de hoja de burbujas de aire

- Máquinas para hacer bolsas

- Blow Film Making Machine

- Blow Film Exusion

- Máquina de hacer películas sopladas

- Máquina de película fundida

- Máquina de recubrimiento

- Línea de extrusión de láminas de espuma EPS / EPE

- Extrusora

- Máquinas laminadoras

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- Maquinaria de extrusión de monofilamento

- Línea de extrusión monofilamento

- PET Strapping Band Extrusion Lines

- Máquinas para fabricar bolsas de plástico

- Coextrusión de película plástica

- Máquinas de fabricación de tubos de plástico

- Máquina de fabricación de tubos de plástico

- Manguera de PVC que hace la máquina

- Máquinas para hacer paja

- Extrusora de doble husillo

- Extrusoras de doble husillo

- Máquina de fabricación de bolsas tejidas

Máquina recicladora de Plástico

- Línea de lavado de botellas

- Trituradora

- Granulador

- Pelletizador

- Pelletizadores

- Pelletizing Machines

- Línea de Reciclaje de Botellas PET

- Línea de lavado en caliente de PET

- Peletizadora De Plastico

- Equipo de reciclaje de plástico para preprocesamiento

- Máquinas de reciclaje de plástico

- Máquina de reciclaje de residuos plásticos

- Reciclaje de líneas

- Reciclaje de la máquina

- Desfibradora De Plastico

- Exprimidores

- Linea de lavado de plastico

- Equipo de Reciclaje de Residuos