|

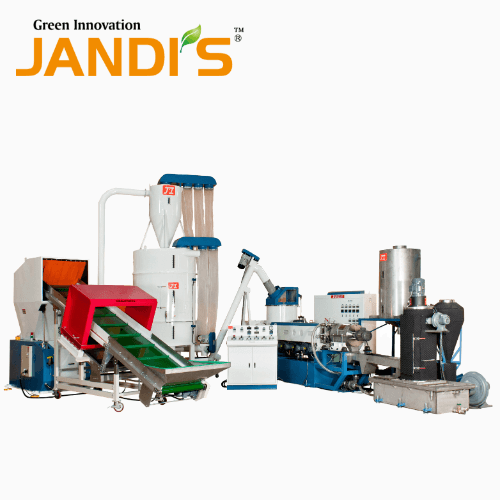

DIE FACE CUTTING TYPE PLASTIC FILM RECYCLING MACHINE |

||||

|

MODEL |

GHR65E |

GHR-85E |

GHR-100E |

GHR-120E |

|

MATERIAL TO BE USED |

HD/LD/LLDPE & P.P. |

|||

|

DENSIFYING TANK |

1 SET, MADE OF STAINLESS STEEL, WITH ROTARY CUTTERS |

|||

|

EXTRUDER SIZE |

65 mm |

85 mm |

100 mm |

120 mm |

|

MOTOR+INVERTER |

50 HP |

75 HP |

100 HP |

125 HP |

|

SCREEN CHANGER |

1 SET, HYDRAULIC SYSTEM |

|||

|

MAX. CAPACITY |

120 KG/HR |

200 KG/HR |

300 KG/HR |

400 KG/HR |

|

CONTROL PANEL |

INDEPENDENT TYPE SWITCH BOARD |

|||

|

DRYING SYSTEM |

CENTRIFUGE UNIT * 1 SET, MADE OF STAINLESS STEEL |

|||

|

STORAGE UNIT |

1 SET, MADE OF STAINLESS STEEL |

|||

|

OPTIONS |

CONVEYOR + METAL DETECTOR, CRUSHER,

SCREW CONVEYOR,

VACUUM PUMP, PRESSURE GAUGE, 2ND EXTRUDER,

FILM ROLL FEEDER, VIBRATING SCREEN, … etc.

|

|||

|

ADVANTAGE TO

USE

CRUSHER

|

1) Easier to handle difference sizes

(loose film, die-cut … etc.)

2) Shorter Densifying type with more even temperature

3) More stable feeding & stable extrusion output, uniform pellet sizes

& better quality

|

|||

|

* Details are available with quotation, specifications could be changed upon request. |

||||

-

Estilo de vida y cosmética

Compresores de aire Sistemas de montaje Máquina de Soldadura Automática Prensa de balas Equipo de control Equipos de refrigeración / Enfriadores industriales Máquinas de corte Equipos de dosificación y medición Secadores y deshumidificadores para materiales plásticos Alimentadores Punzonadoras hidráulicas Equipo de pulverización por inmersión hidráulica Indicadores y sensores Robots industriales Software industrial Equipos de inspección y prueba Máquinas de Carga y Transporte Almacenamiento de material Sistemas de cambio de molde Máquina de pulir de plástico Auxiliares de la máquina de impresión Cambiadores de Filtros / Filtros Separadores Equipo de tratamiento de superficies

-

Todo tipo de botellas y contenedores

Máquinas automáticas de moldeo por soplado Máquinas de Soplado por Capas Máquinas de moldeo por soplado por estaciones Máquinas de cristalización Máquinas de moldeo por soplado eléctricas Máquinas de Soplado por Extrusión Máquinas de Soplado Horizontales Máquinas de Soplado Hidráulicas Máquinas de moldeo por inyección y soplado

-

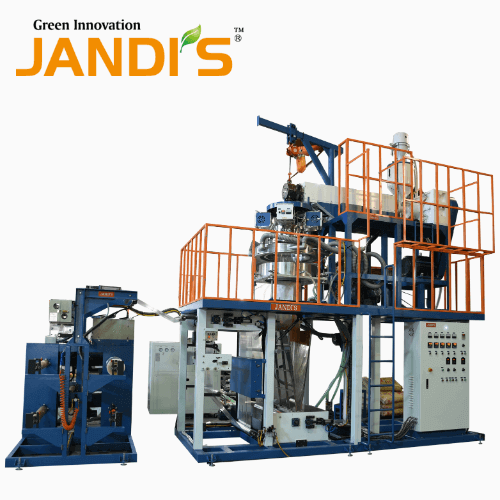

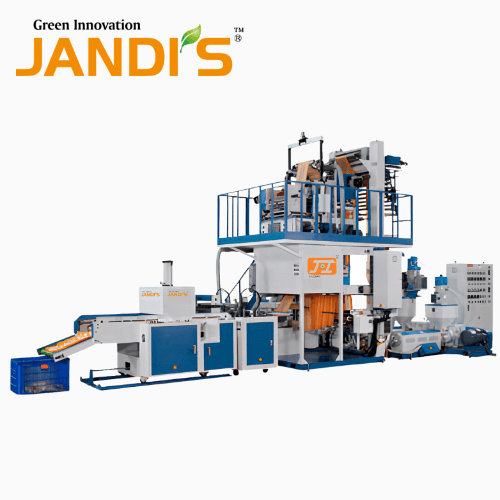

Extrusoras y Líneas de Extrusión

Extrusoras de películas / láminas de burbujas de aire Extrusoras de Película Soplada Máquinas de Soplado por Coextrusión Máquinas de recubrimiento por extrusión Laminadoras por Extrusión Líneas de Extrusión para Filamentos y Hilos Líneas de Extrusión para Tubos y Perfiles Líneas de extrusión de películas y láminas Extrusoras de Espuma Máquinas de Laminación Industrial Medical Tubing Equipment Máquinas para fabricar tubos de plástico Máquinas de revestimiento de huecograbado Extrusoras de Tornillo Simple Máquinas de extrusión de cinta Extrusoras de doble tornillo

- Producto terminado/Producto semiacabado/OEM/ODM

-

Productos relacionados con alimentos y bebidas

Máquina de Moldeo por Inyección Automática Máquinas de Inyección Eléctrica Máquinas de moldeo por inyección de alta presión Máquinas de Inyección Horizontal Máquinas de Inyección con Cierre Hidráulico Máquinas de moldeo por inyección de etiquetado en molde Máquinas de Inyección por Número de Colores Máquinas de moldeo por inyección por bucle Máquinas de moldeo por inyección por platina Máquinas de moldeo por inyección de moldeo por inserción Máquinas de moldeo por inyección de baja presión Máquinas de moldeo por microinyección Máquinas de moldeo por inyección de preformas Máquinas de moldeo por inyección con cierre por palanca Máquinas de Inyección Vertical

- Papelería

-

Máquinas de Empaque

Máquinas de Tapado Máquinas de Empaque para Cápsulas y Comprimidos Máquinas de cartón Máquinas de envasado en seco Máquinas de etiquetado Máquinas de Empaque de Líquidos Máquinas de Sellado Máquinas de Etiquetado Termorretráctil Dispositivos de apilamiento Máquinas flejadoras Máquinas de embalaje de paja Máquinas de envasado al vacío Equipos de Envoltura

- Equipos médicos

-

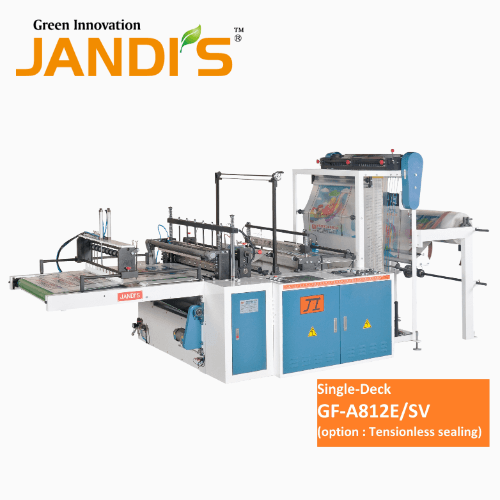

Máquinas de Conversión de Plástico

Máquinas para fabricación de bolsas por aplicación Máquinas de gofrado Máquinas de tejer industriales Máquinas de inspección Línea de Producción de Tejido No Tejido Máquinas para fabricar bolsas de papel Máquinas para fabricar bolsas plásticas Cortadoras y rebobinadoras Máquinas para fabricar sacos tejidos

-

Máquinas de Reciclaje y Procesamiento de Material Plástico

Líneas de reciclaje de botellas Clasificadores y sistemas de desempolvado Líneas de composición Granuladores Línea de fabricación Masterbatch Máquinas de procesamiento de materiales Batidoras y batidoras Otro Trituradoras de plastico Máquinas granuladoras de plástico Trituradoras de plástico Línea de lavado de plástico Máquinas de reciclaje de residuos plásticos

-

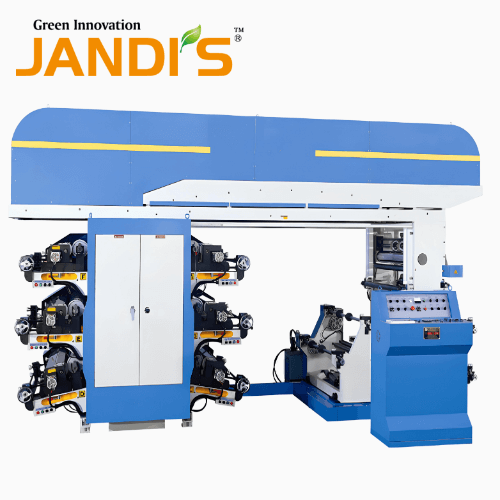

Máquinas de Impresión

Máquinas de impresión flexográfica Máquinas de impresión por transferencia de calor Máquinas de estampación en caliente Máquinas hidrográficas / de transferencia de agua Máquinas de impresión tipográfica Máquinas de impresión en offset Máquinas de tampografía Máquinas secadoras de impresión Máquina de impresión de perfiles de PVC Máquinas de impresión en huecograbado Máquinas de serigrafía Máquina de impresión de bolsas tejidas

-

Materias Primas y Aditivos

Resina ABS Aditivos Aleaciones Resina ASA Material compuesto Plásticos de ingeniería Resina de polietileno de alta densidad Resina de LDPE Masterbatches Otro PA (poliamida) / nailon Resina de PC Resina PE Resina de PET Resina PLA Resina PP PS Resina Gránulos de plástico reciclado Cauchos / Cauchos sintéticos Productos químicos especiales Resina sintética Resina termoendurecible TPE (elastómero termoplástico) TPR (caucho termoplástico) TPU (poliuretano termoplástico)

-

Máquinas de Procesamiento de Caucho

Máquina de moldeo por inyección de baquelita Calandradoras / Mezcladoras Máquinas de moldeo por compresión Amasadoras de dispersión Máquinas de enfriamiento de caucho Máquinas de vulcanización / curado de caucho Máquinas de corte de caucho Líneas de extrusión de caucho Máquinas de moldeo por inyección de caucho Mezcladores de caucho Máquinas de reciclaje de caucho Máquinas de moldeo por inyección de silicona

- Máquinas para la Fabricación de Calzado

- Máquinas de Termoformado

CATEGORÍAS

-

Estilo de vida y cosmética

Máquinas troqueladoras | Cortadora de cuello de tambor | Máquinas de troquelado hidráulico | Máquinas de corte de etiquetas | Máquinas cortadoras de embalaje | Máquina cortadora de rollo de papel a hoja | Máquina cortadora de bolsas tejidas PP | Sheet Cutting Machines | Máquina de encabezado de tubo |

-

Todo tipo de botellas y contenedores

-

Extrusoras y Líneas de Extrusión

Máquina de película soplada PLA / PBAT biodegradable | Máquina de película soplada para bolsas de ropa | Mini máquina de película soplada | Extrusoras de película soplada multicapa | Extrusoras de película soplada de una capa | Máquina de película soplada de plástico | Máquinas de inflado de plástico | Máquina de película soplada soluble en agua PVA | Máquina de soplado de film estirable | Máquina de película soplada con bolsa con cremallera |Línea de extrusión de láminas de ABS | Máquinas de fabricación de membranas agrícolas | Máquinas de extrusión de tableros | Líneas de extrusión de película de fundición | Película de coextrusión | Línea de extrusión de láminas HIPS / PS | Líneas de extrusión de hojas de perfil hueco | Máquina para fabricar láminas | Máquina para fabricar archivos de papelería | Máquina para fabricar películas tubicas |Máquina de revestimiento y laminación | Máquina de laminación en seco / húmedo | Máquinas laminadoras en seco | Recubrimiento y laminación en línea | Máquinas de laminación a base de solvente | Máquinas de laminación sin solvente | Máquinas laminadoras en húmedo | Máquina laminadora de sacos tejidos / papel |

-

Producto terminado/Producto semiacabado/OEM/ODM

-

Productos relacionados con alimentos y bebidas

Toda la máquina de moldeo por inyección vertical eléctrica | Máquinas de moldeo por inyección verticales de sujeción horizontal | Máquinas de moldeo por inyección verticales de mesa giratoria | Máquina de inyección de cebo de plástico blando | Máquina de moldeo por inyección rotativa con barra de unión | Máquinas de moldeo por inyección horizontales con sujeción vertical | Máquina de moldeo por inyección vertical de sujeción vertical |

-

Papelería

-

Máquinas de Empaque

-

Equipos médicos

Tornillo extrusor | Barril de moldeo por inyección | Tornillos de moldeo por inyección | Tornillo y barril para moldeo por soplado | Tornillo y barril para máquinas de película soplada | Tornillo y barril para moldeo por inyección | Tornillo y barril para extrusora de perfiles | Tornillo y barril para inyección de caucho | Tornillo y barril para laminación y extrusora de láminas | Tornillo y barril para extrusoras gemelas | Tornillo y barril para reciclado de residuos de plástico peletizadora | Tornillo para máquina de moldeo por extrusión |

-

Máquinas de Conversión de Plástico

Máquinas para hacer bolsas agrícolas | Máquina para fabricar bolsas de mensajería / carga | Máquina para fabricar bolsas con mangas de flores | Máquina plegable triangular | Máquina para fabricar bolsas de ropa | Máquinas para fabricar guantes | Máquina para fabricar bolsas de lavandería | Máquinas para fabricar máscaras | Máquina para hacer tarjetas de bolsillo | Máquina protectora de hojas | Máquinas para hacer bolsas de camisetas | Máquina para fabricar cubiertas de mesa |Máquina para fabricar bolsas en rollo | Máquina para fabricar bolsas | Máquina para fabricar bolsas de plástico biodegradables | Máquinas para fabricar bolsas de sellado inferior | Máquinas para fabricar bolsas de sellado central | Máquinas para fabricar bolsas de basura | Máquinas para fabricar bolsas gigantes | Máquinas para fabricar bolsas perforadas | Máquinas para fabricar bolsas de plástico | Máquinas para fabricar bolsas de sellado lateral | Máquinas para fabricar bolsas con válvula | Máquina para fabricar bolsas con cremallera / bolsas con agarre |Máquina cortadora y rebobinadora de rollos de papel | Máquina de Perforación y Corte Longitudinal | Inspección de la rebobinadora | Rebobinadoras | Máquina cortadora de caucho | Cortadora rebobinadora sin eje | Inspección de la cortadora | Cortadoras | Cortadoras para hilo plano | Máquina de rebobinado de film estirable | Máquina de torsión de hilo |

-

Máquinas de Reciclaje y Procesamiento de Material Plástico

-

Máquinas de Impresión

Máquinas de impresión flexográfica tipo CI | Máquinas de impresión flexográfica en línea | Impresora flexográfica de bolsas jumbo | Mini máquina de impresión flexográfica | Máquina de impresión flexográfica de tipo fuera de línea | Máquina de impresión flexográfica de carrete a carrete | Máquinas de impresión flexográfica tipo pila |

-

Materias Primas y Aditivos

-

Máquinas de Procesamiento de Caucho

-

Máquinas para la Fabricación de Calzado

-

Máquinas de Termoformado