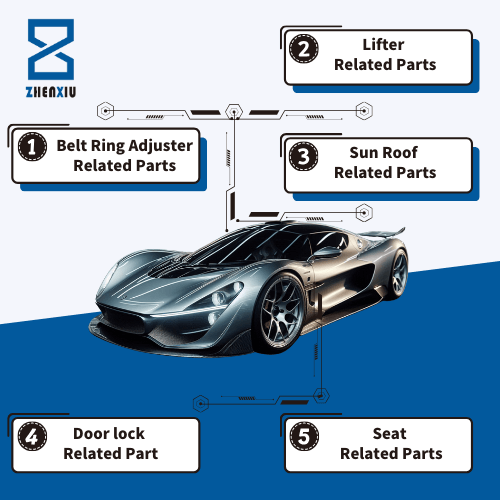

Door lock Related Part

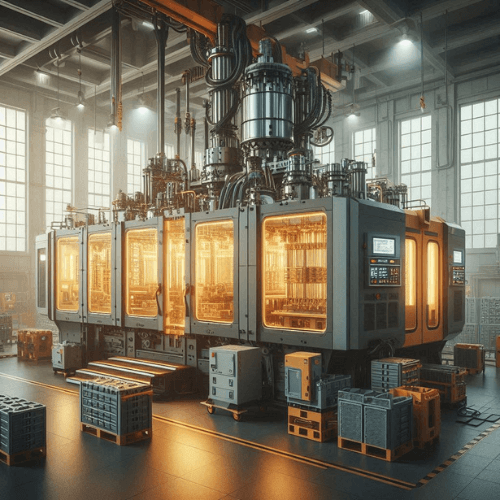

This product is made of PP+GF (Glass Fiber Reinforced Polypropylene), offering high strength, impact resistance, heat resistance, and low deformation rate, ensuring the stability and durability of large panels and main boards in high-load environments. It is designed for applications in structural support, industrial equipment, and automotive interior and exterior components, delivering excellent mechanical performance and long-term stability. Manufactured using a 1600-ton large injection molding machine, this product enables the production of large-sized, high-precision plastic components, ensuring superior structural rigidity and consistency to meet various large-component requirements. Additionally, compared to metal parts, PP+GF provides both high strength and lightweight advantages, effectively reducing product weight.

Molde de inyección de plástico OEM para cubierta de cubierta de coche

CATEGORÍAS : Moldes de Inyección

Tamaño del molde: 1200W x 1030L x 950H mm Peso del molde: 6600kg Máquina de inyección: 950TON

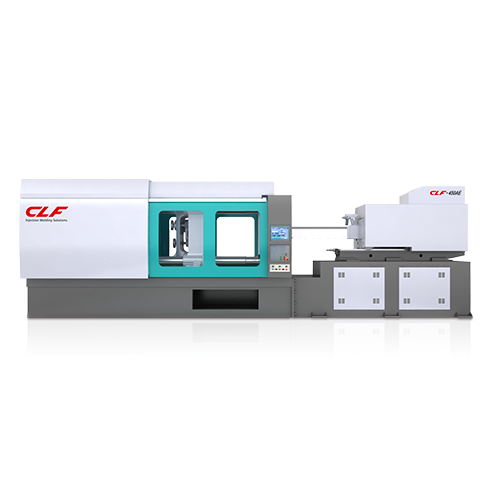

Serie AE - Toda la máquina de moldeo por inyección de plástico eléctrico

CATEGORÍAS : Máquinas de Inyección Eléctrica

Basado en años de experiencia de cooperación OEM / ODM con una reconocida compañía japonesa, CLF ha acumulado una amplia experiencia en este campo de tecnología ...

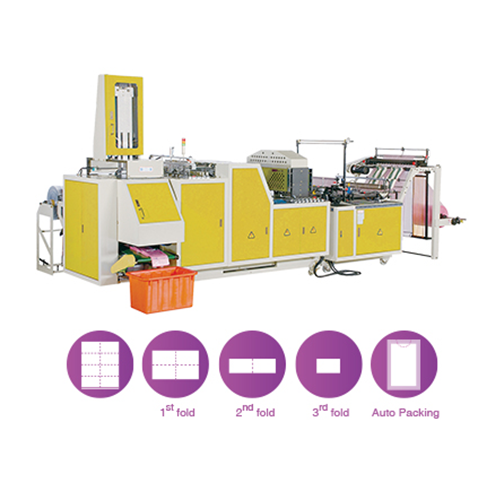

Máquina para hacer bolsas de camisetas de alta velocidad de dos líneas (sistema de corte en caliente) + Sistema de embalaje automático TPFA-V + AP

CATEGORÍAS : Máquinas para fabricación de bolsas por aplicación

Solución de embalaje automático: ahorra aún más trabajo de recolección mediante la solución de embalaje automático. Las pilas terminadas se autoempacan individualmente en bolsas exteriores impresas. Soluciones personalizadas disponibles Sistema de corte en caliente de alta velocidad - Para bolsas tipo camiseta estampadas. La fotocélula y el servo registran la posición de impresión precisa. Sistema de corte en caliente de alta velocidad disponible en sistemas de 200/250/300 rpm. Sistema de doble servo - 2 servos que controlan 2 líneas con registro de impresión con precisión.

Manufacture of automobile parts and accessories

CATEGORÍAS : Productos moldeados por inyección

ZHEN XIU Plastic Enterprise Co., LTD specializes in manufacturing injection-molded components for electronics, home appliances, automotive, and motorcycle parts. With a 600-ping production facility and 17 injection molding machines of varying tonnage, the company has been a trusted OEM partner for major automotive and motorcycle component manufacturers since 1986. Its products have successfully entered markets in Asia and the Americas, backed by ISO 9001:2015 certification for quality management.

Máquina de corte y sellado de alta velocidad completamente automática, 3 plegadoras y empacadoras

CATEGORÍAS : Máquinas de Sellado

Máquina automática de corte y sellado de alta velocidad, 3 máquinas plegadoras y empacadoras con control de servomotor. ‧ Sellado y corte, 3 plegables, autoembalaje. ‧ Control computarizado de pantalla táctil humana, fácil operación.

85-150 ton injection molding machine product

CATEGORÍAS : Productos moldeados por inyección

This 85-150 ton injection molding machine is designed for high-precision plastic product manufacturing, including automotive components, electronic parts, appliance housings, medical devices, and consumer goods. Equipped with a high-efficiency servo-driven system, it ensures stable injection pressure and precise control, delivering superior molding quality. With a high-rigidity clamping structure and an optimized hydraulic system, this machine offers durability and operational efficiency. It supports various plastic materials (PP, PE, ABS, PC, PA, etc.) and can be customized with multi-stage injection units and robotic interfaces for full automation, reducing labor costs and increasing productivity. Ideal for OEM manufacturers, plastic molding factories, and precision molding industries, this model meets modern production demands with efficiency and precision.

Válvulas antirretorno (punta de tornillo)

CATEGORÍAS : Valvulas

La clave de la inyección: proporcionamos muchos materiales para todo tipo de diseño. Tanto para ODM como para OEM están disponibles para usted. Las válvulas antirretorno desempeñan un papel muy importante para su proceso de moldeo y Tan Star siempre se dedica a investigar y desarrollar una nueva solución para todos los desafíos que se presenten en el mundo.

DESIGN AND DEVELOPMENT PARTNER

CATEGORÍAS : Moldes de Inyección

JDM / ODM SERVICES When bringing a new product to market or re-launching an existing product with new features, key success metrics are quality and timing t o market. Either or both may be negatively impacted if the design proves difficult to manufacture especially if there is a rapid demand for increased volume. A design partner who is well integrated with a full service manufacturing system knows how to minimize risk. Our design teams have executed numerous design-build projects for customers across a variety of industries on a global scale. We incorporate manufacturability, assembly and test principles into the EDI-early design stages involved of a product to assure seamless production. JDM/ODM services include : To use the PLM system to monitor the product life cycle management. Concept Development Mechanical Drawing Layout Documentation Verification Material Management & Sourcing Rapid Prototyping & Soft Tooling Initial Pilot Builds & DFM αTest /βTest/ Burn-in Tooling & molding in house Final Assembly Following the design phase of your product, we build prototypes to test the DFM manufacturablity and any industry compliances. Prototyping may occur multiple times at various points in the design and planning stages for a project. Once all the design and manufacturing issues are worked out, we can rapidly transition into full-scale production. Please visit our Contract Assembly page to learn more about our assembly facilities. OEM Our Original Equipment Manufacturer (OEM) service is responsible for designing and building a product according to a customer’s own specifications. Our service also includes & DFM,EDI,3D printer rapid prototype global distribution and returned product factory repair, which can greatly reduce customer’s overall production costs.