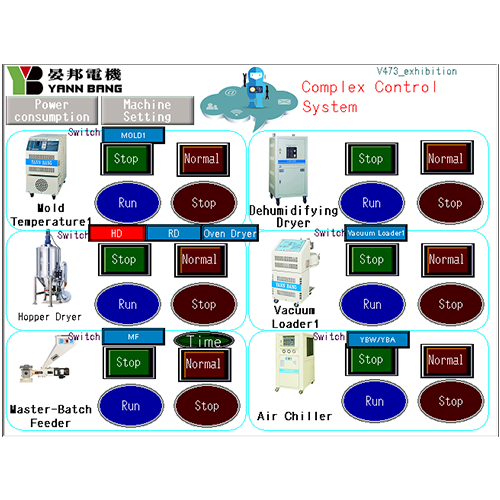

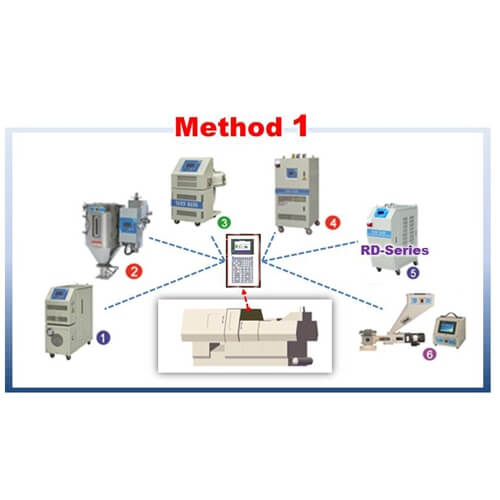

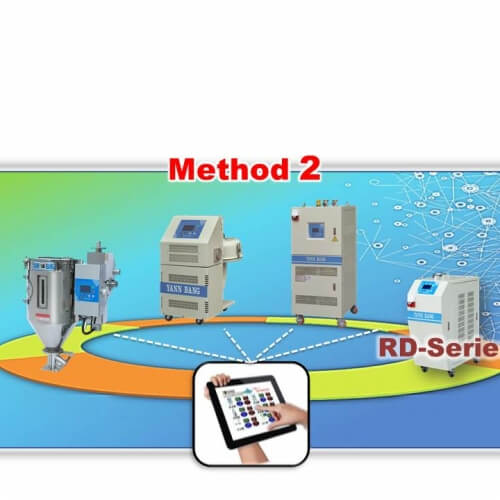

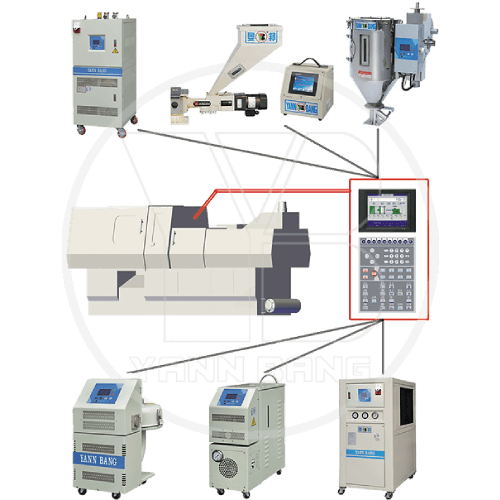

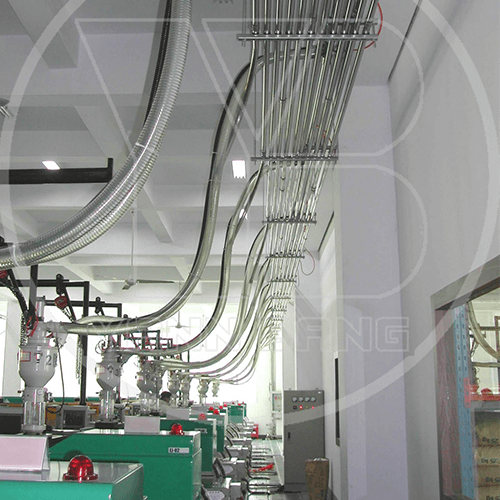

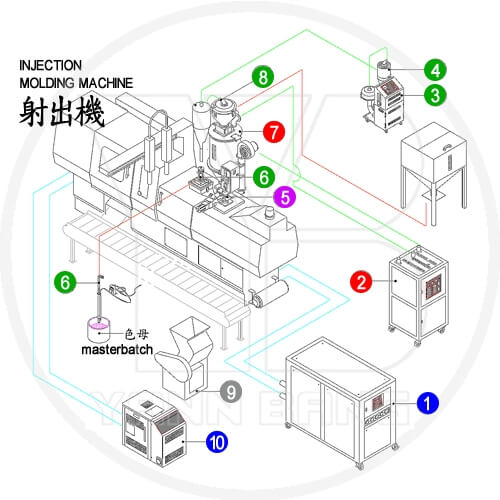

WT(Wise-Transit) Net 4.0

The automatic plastics processing can be controlled by the method of Industry 4.0, Modbus Protocol and RS-485, supplied by Yann Bang, professional experienced programming design and related compatible equipment, to offer you a best solution to a smart factory.

-

Provide the complete production resume for tracking and analyzing.

-

Record the best parameter setting and the experience can be inherited.

-

Machine maintenance can be reffered to and reminded.

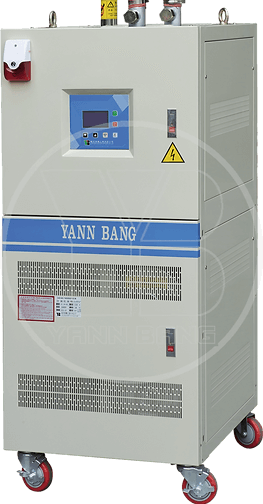

Mold Temperature Controller (YBMI/YBMD)

Steady controlled temperature makes plastic molding accurate in size and consistent with quality. Accurate mold temperature solves the problem of plastic flow patterns, reducing flow and weld lines, gloss appearance, record grooves effect, silver streaking, stress-whitening, warping, and etc....

P.I.D temperature controllers are used for accurate control of temperature within±1℃.

Two-step-heating selector makes rapid temperature increasing possible when require thus saving time and power specially start up in the morning. Patented “Heat-insulated” design improves your safety, extend the machine’s lifetime and make maintenance more efficiently.

-

YBMI : By oil, suit for long-term continuous operation, keep the temperature steady, no flash on tiny and thin products, and no corrosion. However, the heater may be damaged if you do not use the thermo oil correctly or change oil routinely. Recommend to choose oil-type mold temperature controller when your required temperature is 150℃ or above.

-

YBMD : By water, heating up faster, cooling better, harmless to your mold and more economic than oil type for maintenance and cost. However, the water boiling point is low and the element of different water may occur corrosion or limescale to affect the heat exchange and products quality. Recommend to choose water-type mold temperature controller when your required temperature is 150℃ or below.

La tolva aislada única puede soportar el calentamiento repetidamente a alta temperatura. Alta seguridad y buena deshumidificación. El peso ligero es fácil de instalar directamente en la máquina de moldeo. El diseño de una unidad de acero inoxidable y pulido es libre de polvo y limpieza.

El diseño separado de un soplador y una tolva de succión con gran potencia es adecuado para el transporte de larga distancia. Eso mantiene su resina alejada de la contaminación y extiende los puntos de succión fácilmente para futuras necesidades.

1. Importación de nido de abeja de fibra cerámica, supere el punto de rocío por debajo de -40 °C de aire seco

2. Control de microprocesador inteligente y protector contra sobrecalentamiento de primera calidad.

3. Controlador de temperatura PID preciso.

4. Relé de estado sólido (SSR) y dispositivos de protección bien diseñados.

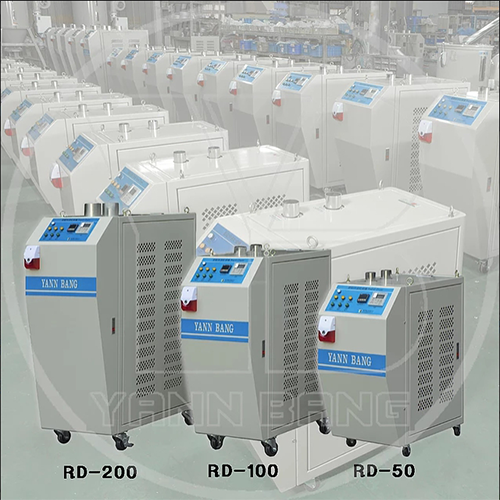

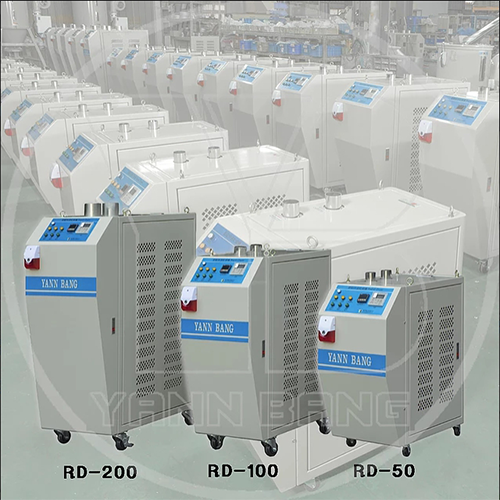

Rapid Dryer (RD)

Without replace your old hopper dryer, use this new dryer to dry faster with better quality and to upgrade production more efficiently.

1. Wide application. Suit to numerous material such as PC, PMMA, PA46, PPS, NYLON and some PET/PETG.

2. Save time and energy. Patented technology significantly shortens the drying time. Normally NYLON takes four hours to dry. Work with Yann Bang’s rapid dryer (RD), it only takes two hours to dry completely and ready to use. RD can decrease 50% of drying hours and save 50% of energy for you.

3. Upgrade energy save. Combine with Yann Bang’s Energy-efficient Hopper dryer can save more energy obviously.

4. Increase yield rate of output. Moisture content can be reduced to 0.02% (depend on the initial moisture content of resin), improve the drying quality of resin, and lower defective products.

5. Easy maintenance. Install with plug-in air filter and dust collector (oil collector) that you can unload easily to clean and replace parts.

El masterbatch se mezcla automáticamente con su resina virgen en la tolva de la máquina. Ya no necesita precolorear ni premezclar su resina. Ahorra mano de obra, resina, costes de stock y mantiene limpio el entorno de trabajo.

La unidad mezcla y dosifica masterbatch, aditivos, polvos de flujo libre, resinas molidas y vírgenes para garantizar una mezcla uniforme y precisa que da como resultado una mejor calidad del producto y menos rechazos.