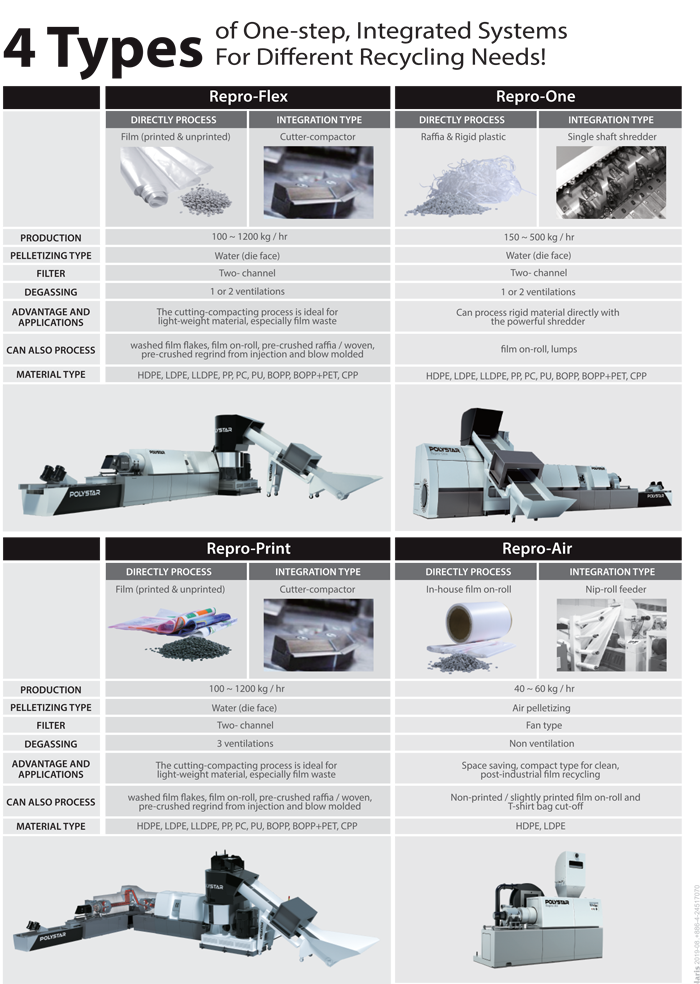

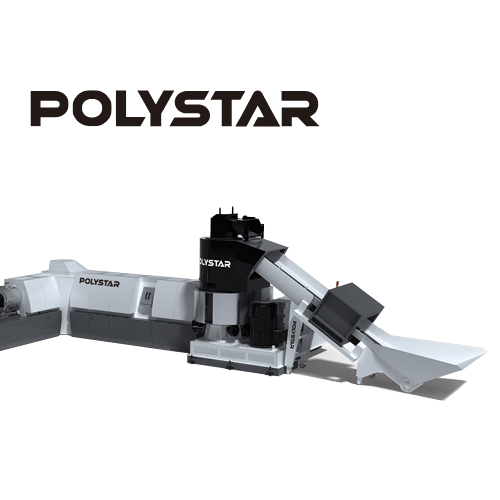

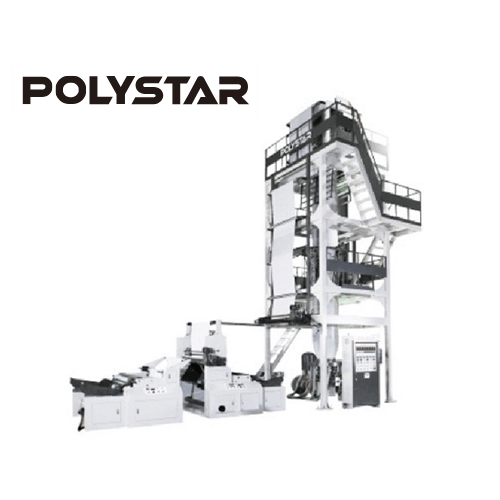

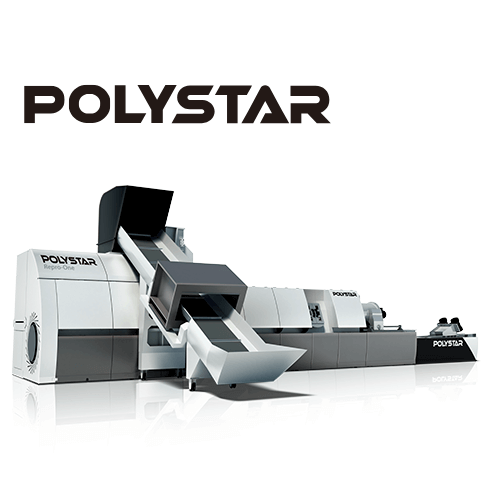

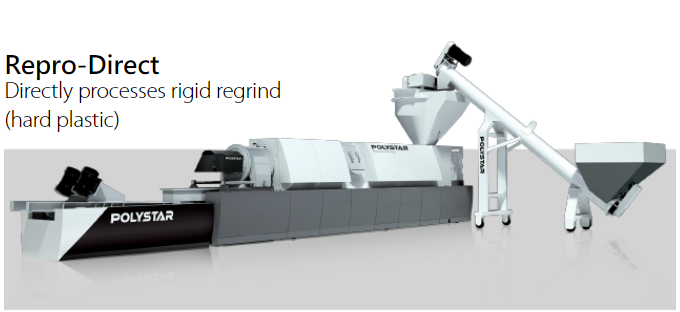

Una línea de reciclaje flexible para materiales duros y blandos

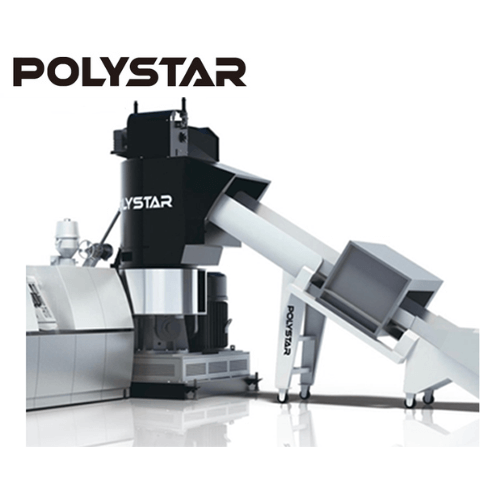

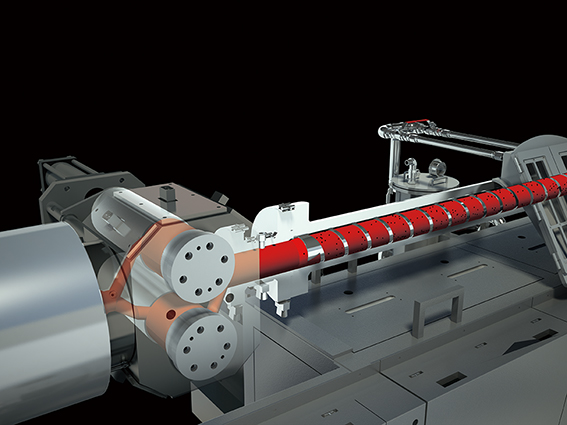

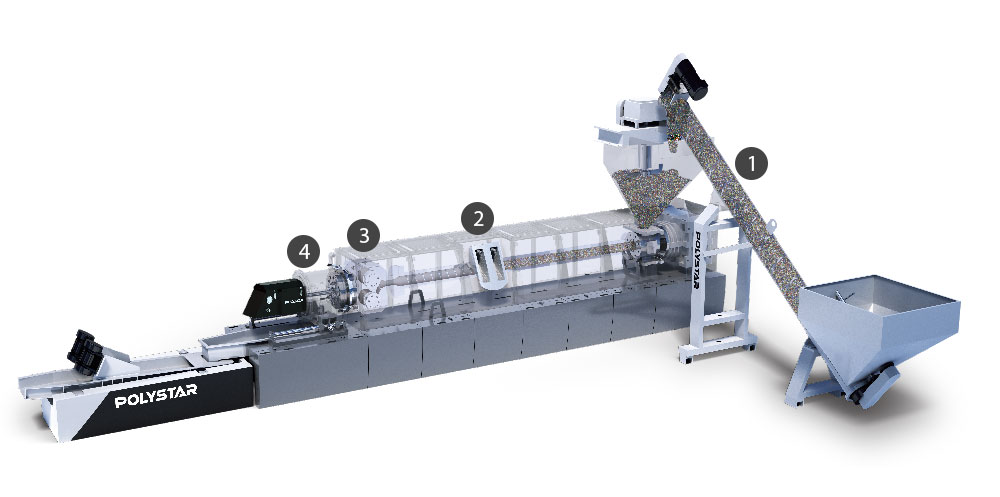

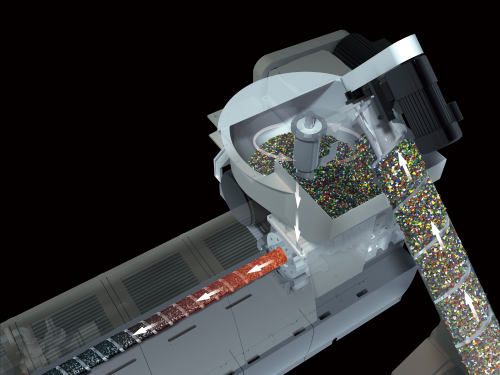

1. Alimentación directa por alimentador de tornillo.

- Alimentación muy rápida y estable desde la tolva directamente a la extrusora

2. 10% menos de consumo de energía; 20% mayor producción; 100% reutilización de gránulos

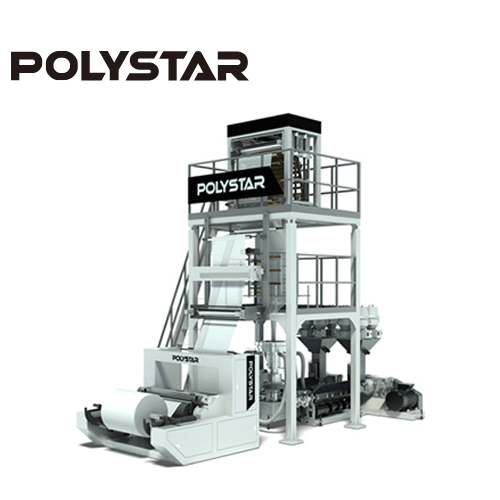

- Los gránulos producidos por la máquina de reciclaje se pueden volver a colocar directamente en la línea de producción, en la mayoría de los casos para procesos de extrusión de película soplada o tubería.

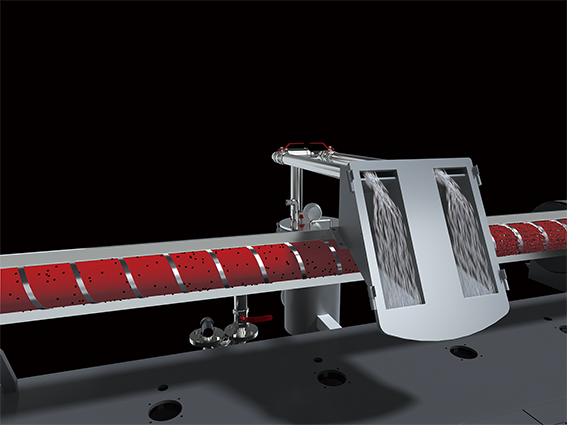

3. Desgasificación de alta eficiencia conectada con bomba de vacío para la protección del medio ambiente

- Capaz de procesar material impreso y no impreso

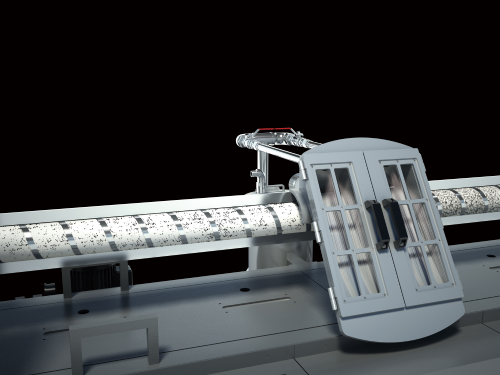

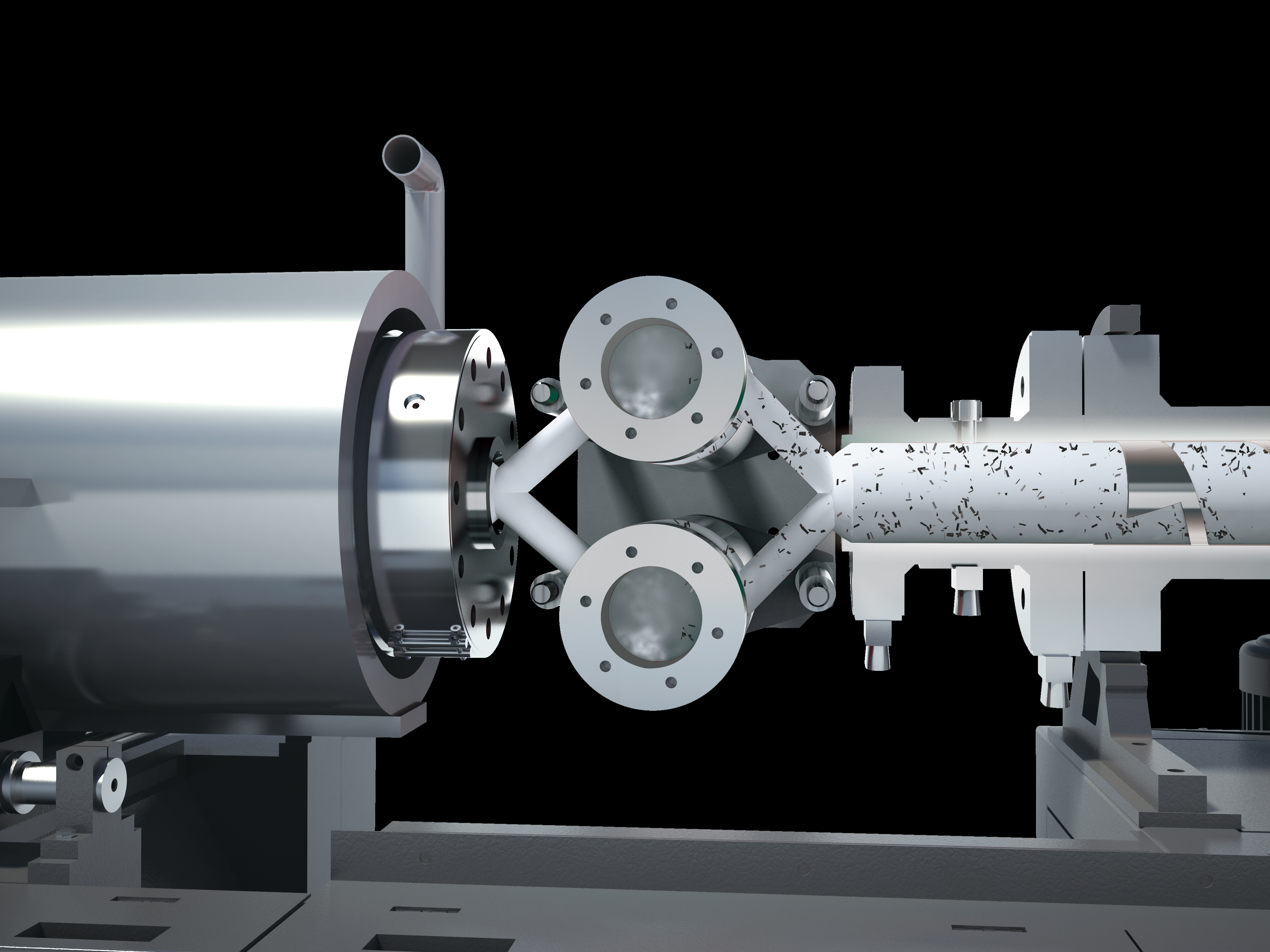

4. Sistema de filtración de pistón de doble canal Non-Stop

- Filtro con sistema de doble canal para un funcionamiento continuo y reduce el tiempo de inactividad de la máquina

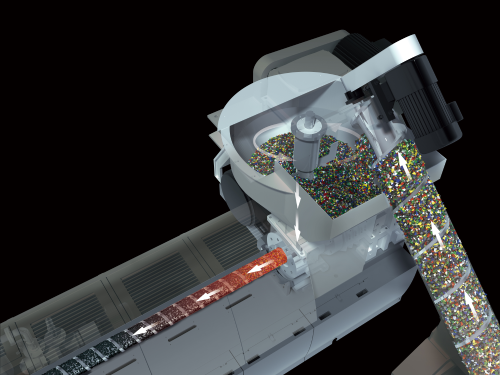

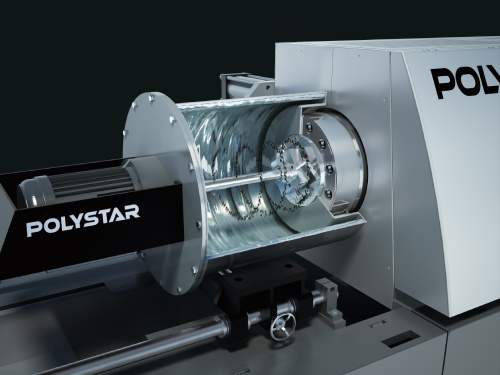

5. Automatización Tecnología de peletización en la cara del troquel para producir gránulos uniformes

- Produce gránulos de plástico de alta calidad para su reprocesamiento

6. Sistema inteligente de detección de presión y control de alarma.

7. Elegante diseño industrial

8. Polystar Machinery puede personalizar cada sección de la maquinaria según las necesidades del cliente.

- Forma del material : Películas pretrituradas, bolsas, láminas, mallas, espuma, cintas, rafia, triturado, escamas, gránulos, desechos, astillas, borde recortado

- Tipo de material : HDPE, LDPE, LLDPE, PP, BOPP, PA, PC, PS, PU, EPS, ABS

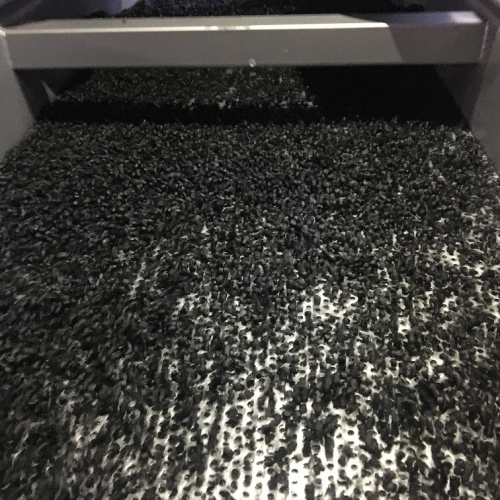

Regrin de plástico duro

Material lavado

Gránulos

HDPE-botellas de leche

- Reutilización del 100 % de los gránulos directamente en su línea de producción

- Degradación mínima del material sin cambio de propiedades

- Reducción de costes de producción mediante el reprocesamiento de sus propios residuos industriales

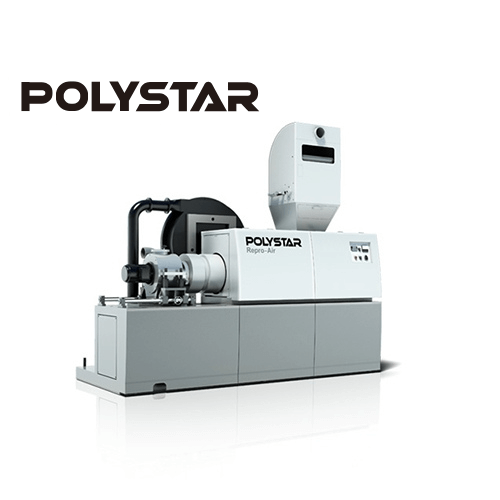

1. Alimentación directa

- Por alimentador de tornillo o cinta transportadora

2. Doble desgasificación

- Capaz de procesar material impreso y no impreso

3. Filtración de dos canales

- Filtro con sistema de doble canal

- Para un funcionamiento ininterrumpido y reduce el tiempo de inactividad de la máquina

4. Granulación de cara de troquel fácil de usar

- Ajuste automático de la velocidad de granulación

- Produce gránulos de tamaño más uniforme sin intervención de mano de obra. - Ajuste automático de la presión de las cuchillas

- Menos tiempo de inactividad de la máquina, más fácil de cambiar y ajustar las cuchillas

Producto: pellets / gránulos / resinas de plástico & nbsp;

Alimentación: Transportador de tornillo, cinta transportadora y alimentación de tolva

Extrusora: tornillo simple, extrusión de una etapa

Diámetro del tornillo: disponible de 65 mm a 165 mm (personalizado)

Tornillo L / D: 30/1, 34/1 o 36/1 (personalizado)

Material del tornillo: SACM-645 o bimetálico & nbsp;

Ventilación: Desgasificación ventilada doble, ventilación única o sin ventilación (personalizada)

Tipo de corte: peletizado en caliente (anillo de agua)

Tipo de refrigeración: refrigerado por agua & nbsp;

Voltaje: personalizado & nbsp;

Componentes de la máquina: Transportador de tornillo / cinta transportadora, tanque de alimentación de tolva, alimentador de fuerza, extrusor, unidad de peletización, unidad de enfriamiento y secado de pellets y tanque de almacenamiento. & Nbsp;

Salida: 100 ~ 1000 kg por hora (dependiendo del tamaño del extrusor)

Tipo de material: HDPE, LDPE, LLDPE, PP, BOPP, EPS, PU, PC, ABS

Forma del material: películas precortadas, bolsas, sábanas, red, espuma, cintas, rafia, triturado, copos, gránulos, restos, virutas, bordes recortados

Producción:

80~100 kg/h

Diámetro del tornillo: 65 mm

Repro-Direct65

Rectificado/botella

Producción:

100~180 kg/h

Diámetro del tornillo: 85 mm

Repro-Direct85

Rectificado/botella

Producción:

200~300 kg/h

Diámetro del tornillo: 100 mm

Repro-Direct100

Rectificado/botella

Producción:

300~450 kg/h

Diámetro del tornillo: 120 mm

Repro-Direct120

Rectificado/botella

Producción:

450~700 kg/h

Diámetro del tornillo: 150 mm

Repro-Direct150

Rectificado/botella

Producción:

700~900 kg/h

Diámetro del tornillo: 165 mm

Repro-Direct165

Rectificado/botella

Producción:

900~1100 kg/h

Diámetro del tornillo: 180 mm

Repro-Direct180

Rectificado/botella

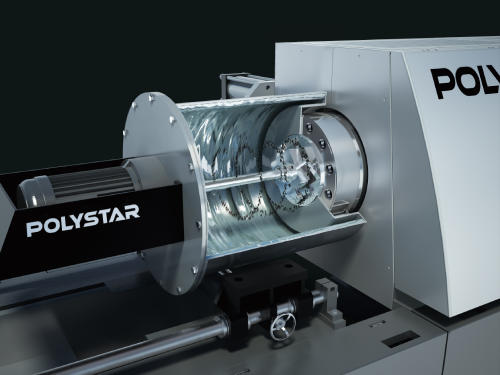

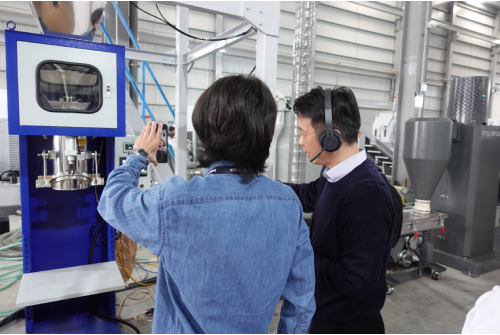

Sweden Post-Consumer Recycler Intelligent Recycling with POLYSTAR Repro-Direct

The Sweden reputed recycler, which is the professional recycler and collects plastics from waste electrical and electronic equipment (WEEE) and other products from the automotive sector such as bumpers, battery packs, engine piping, etc.

These Post-Consumer waste are contained with iron particles, wood pieces and paper labels…etc. Thus, the turnkey solution from the material sorting, cleaning, drying and processing into the high end quality recycled pellets are the essential factors toward business success.

Thanks to the simplest yet powerful design of POLYSTAR’s recycling machine, plus integrate with FIMIC’s advanced auto cleaning filtration system. It ensures the excellent filtration efficiency and continuously high output performance.

The collected post-consumer ABS and PS regrind have the higher bulk density of 200-600 kg/m3 and is with more fluidity.

Both properties contribute to the washing and sorting processes working better and the material thus being available in a more clean-sorted form. Meanwhile, POLYSTAR customize the tailor-made screw profile design which is optimized the melting flow paths and activities for both materials, and the specific pelletizing die head design is also beneficial for stabilizing the quality and consistency of the pelletizing process.

Moreover, the customer request the intelligent water level sensing control on the vibration tank to optimize the cooling efficiency in time.

With POLYSTAR simplified and user-friendly structure design, the cooling temperature can be visible monitored and controlled via intelligent PLC control system, the average output of its Repro Direct 150 is reached up to 700~800 kg/hr for our business benefit constant contribution, impressively described by the factory director.

As a professional recycler in the post consumer recycling industry, the excellent quality of the recycled pellets and high efficiency of machinery operation are the most important two indicators we pursue.

Hence, we consider that the simplest yet powerful machine of POLYSTAR, and its high degree of fully automation control system can be met with our expectation, says by the customer.

By adopting with SIEMENS state of art PLC plus POLYSTAR intelligent HMI touch panel control system, the energy and current consumption can be monitored in-time, and the feeding, cutter compacting, extrusion, filtration, pelletizing units are flexible switched control and data setting precisely. The other value-added functionality of this smart PLC control system including as below:

1.Preheating sequence of the extruder temperature for higher degree of automation.

2.Process parameter data setting ,recording and simulation

3.Operation data curve analysis

4.Operation error alarm and in-time report

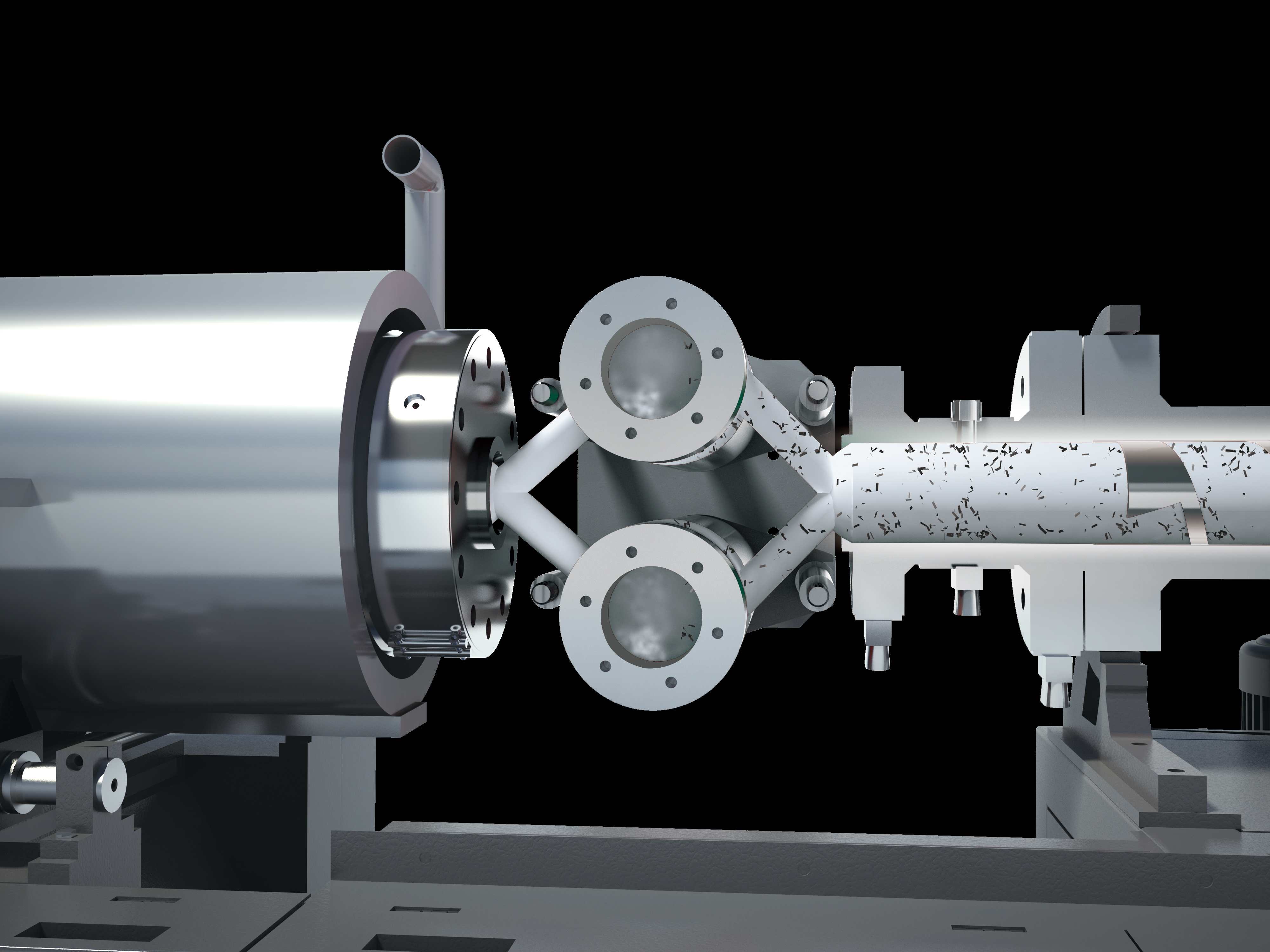

For processing the post consumer grade waste material, the efficiency of filtration system should be the critical factors for the higher quality and stable throughput.

After comparison of several advanced melt filter solution by the client itself, they finally choose Italian FIMIC auto-cleaning filtration system as the higher cost effective solution.

Thanks to the similar “ Simple yet Powerful” design concept and mentality of FIMIC. It can be perfectly integrated with POLYSTAR recycling line and perform the best filtration capability via mutual technical cooperation.

The major advantage and core value of FIMIC auto-cleaning filtration system is indicated as below:

- Lower Sensitivity: The scraper collects immediately the contaminations from the screen and avoid the contamination permanence or damage to the screen.

- Lower Maintenance Cost: The cost of spare parts are approximately 5 time less expensive than other suppliers.

- Easier Operation: Simplified configuration structure design, need only 30 minutes and one operator to replace a screen efficiently.

- Less Production Loss: As a general rule, the max. melt losses with FIMIC technology only reach to 0,5% - 1%.

- Specific Valve Discharging Technology: The valve can be automatically adjusted according to the amount of contamination accumulated, to ensures the maximum clean melt material keeping inside.

Thus, the customer put back the recycled pellets into the injection molding machine for production and verify the impact resistance, tensile strength and flexural strength of the end product. As a result, the quality is met with our criteria and expectation, POLYSTAR proven its merits not only at its machinery, but also with the excellent quality of recycled pellets. A proportion of the recycled pellets will be mixed with the confidential additives and powder formulation into compounding process and develop the reinforced material for high-value market.

We are committed to maximizing waste utilization and afford the social responsibility for global environment protection, emphasized by the customer.

Work with POLYSTAR

An experienced market leader in the recycling field, especially for the recycling of packaging film

More than 1,700 Polystar plastic recycling machines have been installed worldwide since 1988

Proven success and positive feedback from satisfied customers in 105 countries

Flexible, personalized machine design to meet your specific requirement and factory layout

Top quality components used for the machines: Energy saving and high performance motors

Cost-effective machine: Lower investment cost for a high quality and durable machine

Service and Communication