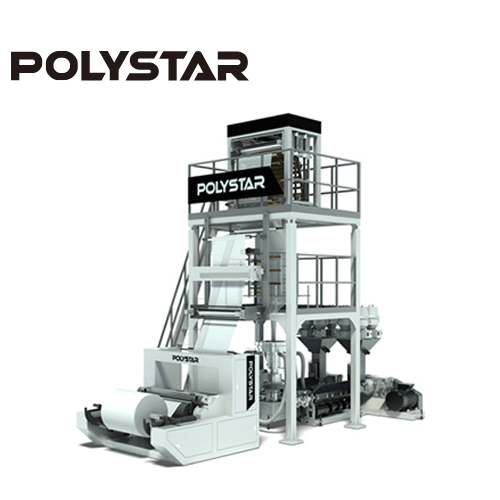

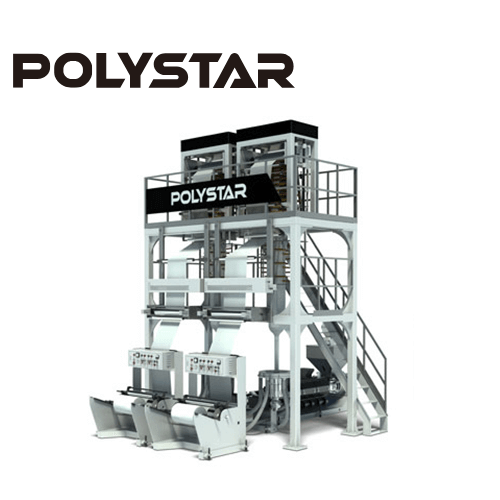

● & nbsp;Ideal para residuos de rafia y película

● & nbsp;Adecuado para el reciclaje de residuos plásticos rígidos

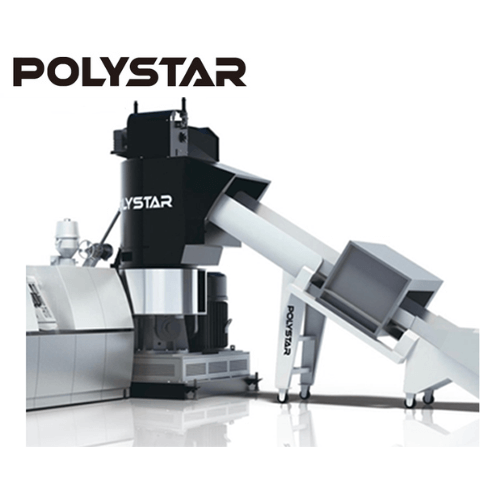

● & nbsp;Shredder integrada solución de reciclaje pre-triturado sólido

● & nbsp;Desgasificación de alta eficiencia conectada con la bomba de vacío para la protección del medio ambiente

● & nbsp;Sistema de filtración de pistón de dos canales sin detención

● & nbsp;Automatización Tecnología de granulación de moldes para pellets uniformes que producen

● & nbsp;sistema de detección de presión ntelligent y control de alarma

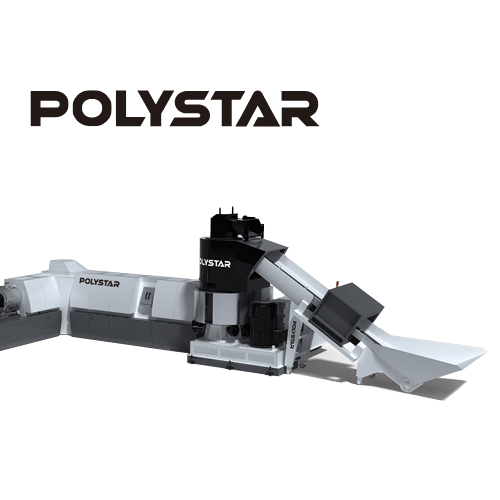

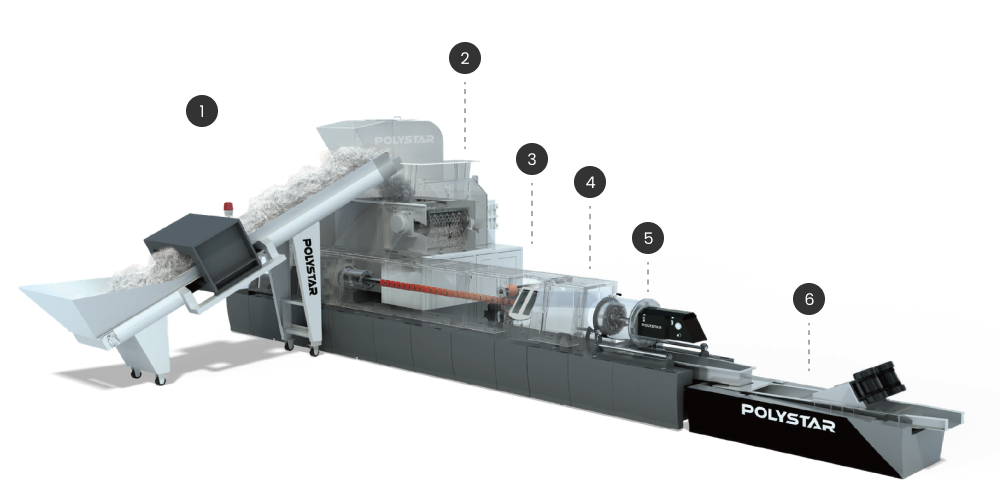

1. Feeding System

Feeding of scraps (raffia, film, lumps) is simple by a conveyor.

2. Shredding

Shredder integrated & Direct feeding to extruder: Powerful yet gentle shredder, efficient size reduction with minimal material degradation. Fast and stable feeding from the shredder into the extruder.

3. Filtration

Screen change with dual channel system: For non-stop operation and prevents material from leaking.

4. Degassing

Two-zone degassing (double-vented degasification): Able to process films with larger printed area and some water content.

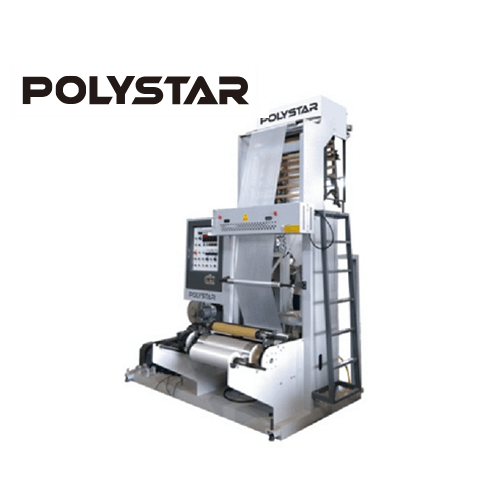

5. Pelletization

Hot die face pelletizer: Produces high-quality plastic pellets for reprocessing.

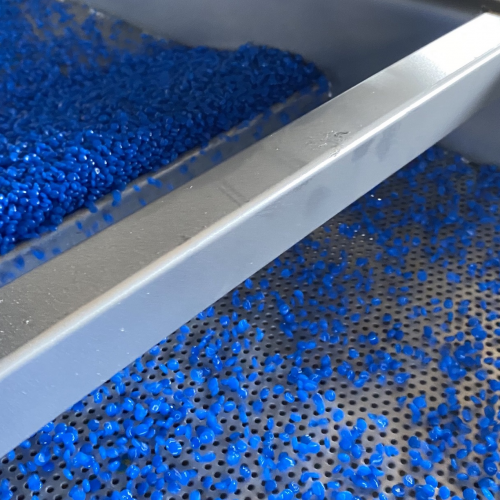

6. Recycled Pellets

The plastic pellets can be put directly back into the production line such as blown film extrusion and pipe extrusion.

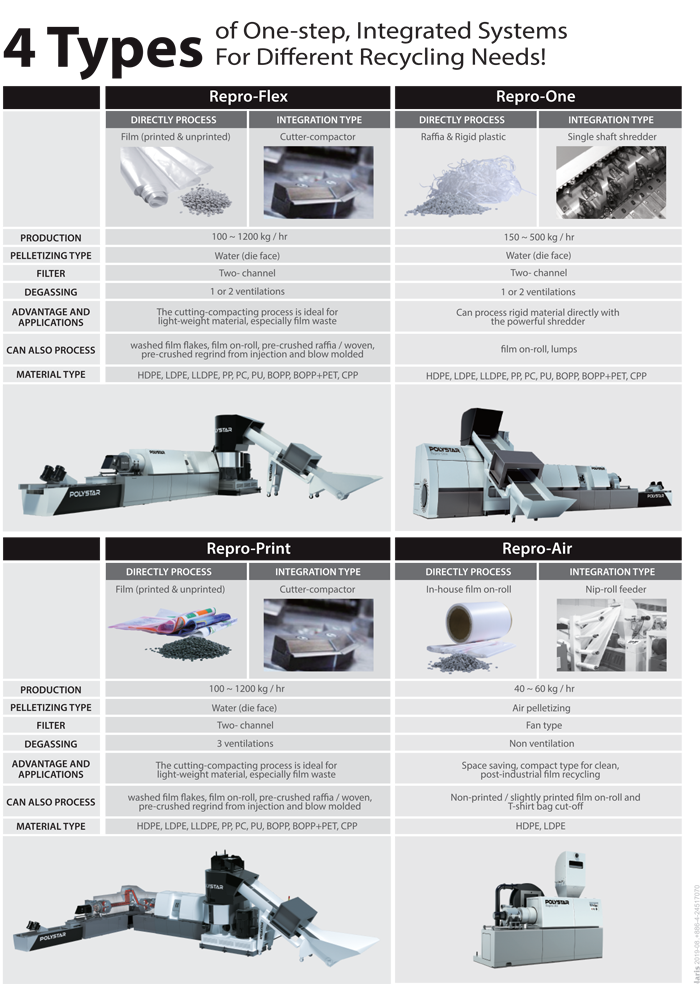

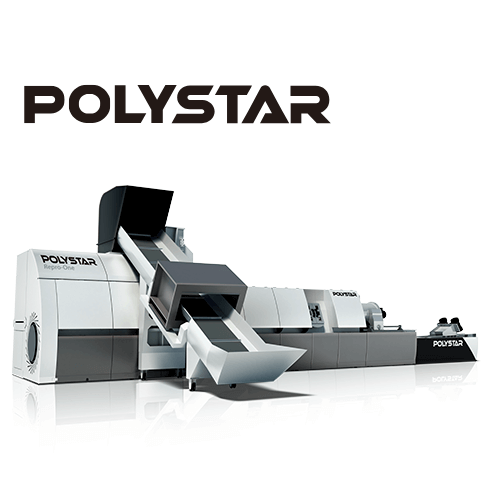

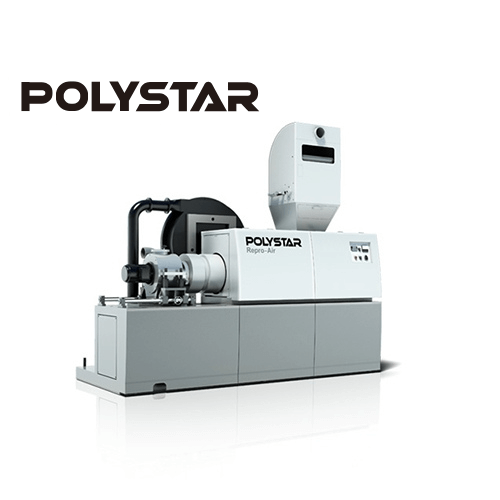

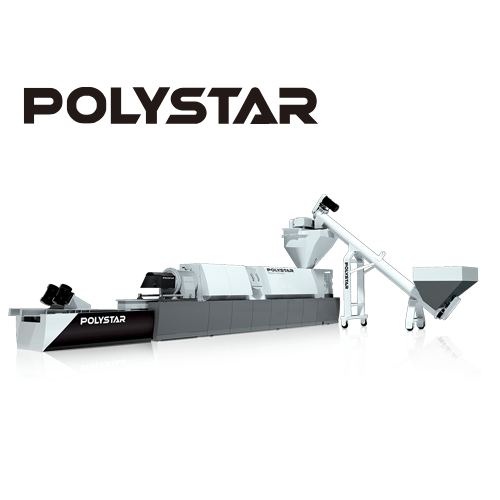

| Nombre del modelo | Repro-One |

| Producto final | Pellets de plástico / gránulo |

| Componentes de la máquina | Cinta transportadora, trituradora de un solo eje, extrusora, unidad de peletización, unidad de refrigeración por agua, unidad de secado, tanque silo |

| Reciclaje de material | HDPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, EPS |

| Rango de salida | 150 ~ 500 kgs / hora |

| Alimentación | Cinta transportadora |

| Diámetro del tornillo | 85 ~ 120 mm (personalizado) |

| Tornillo L / D | 30 / 1,32 / 1,34 / 1,36 / 1 (personalizado) |

| Tornillo de material | SACM-465 o bimetálico |

| Desgasificación | Desgasificación ventilada simple o doble, no revelada para película no impresa (personalizada) |

| Tipo de corte | Peletizado en caliente (peletizador de anillo de agua) |

| Enfriamiento | Enfriado hidráulicamente |

| voltaje | Personalizado según solicitud (por ejemplo: EE.UU. 480V 60Hz, México 440V / 220V 60Hz, Arabia Saudita 380V 60Hz, Nigeria 415V 50Hz ...) |

| Dispositivos opcionales | Detector de metales (S + S), alimentador de aditivos para masterbatch, secador centrífugo para secado |

| El tiempo de entrega | 90 ~ 150 días para la máquina personalizada. En stock máquinas disponibles |

| Garantía | 1 año |

| Asistencia técnica | Ingenieros disponibles para dar servicio a maquinaria en el exterior |

| Modelo | Repro-One85 | Repro-One100 | Repro-One120 |

| Salida | 150-250 kgs / hora & nbsp; | 300-400 kgs / hora & nbsp; | 400-500 kgs / hora & nbsp; |

| 6 toneladas / día | 9.6 toneladas / día | 12 toneladas / día | |

| 180 toneladas / mes & nbsp; | 288 toneladas / mes & nbsp; | 360 toneladas / mes & nbsp; | |

| Diámetro del tornillo | & nbsp; 85mm | 100 mm | 120 mm |

Plast India an unprecedented Success

The heavy duty single shaft shredder integrated machine generated great interest among visitors from India and other parts of the world at the fair. From day to the last day of the exhibition, Polystar carried our live demonstration of the machine processing different types of material, including PP raffia scrap, purging (lumps), PP FIBC process scrap – bags, webbing, fabric, HDPE, LLDPE film scrap, both printed and unprinted. Visiting customers were able to take a much closer look at the machine performance and the quality of the pellets produced.

The Repro One machine was sold to a PP raffia/PP non-woven manufacturer who will process their in-house process waste and reuse the high quality pellets again in their production process. This manufacturer is one of the recognized producers of PP woven and non-woven fabric and bags in India.

7 sets of Polystar’s recycling machines have been sold at the exhibition along with many more pending projects which are likely to be finalized by mid 2015. Thousands of interested visitors in India registered themselves in Polystar’s stand in 6 days.

The one step recycling machine Repro One has an integration of a heavy duty shredder which eliminates the need of pre-cutting/pre-shredding even hard plastic waste, feeding the waste directly from the shredder into the extruder at a very fast and constant rate without over heating the material. Equipped with double degassing and die face pelletizing, the line is the ideal equipment for processing all types of plastic scrap including PP raffia and woven waste, film scrap, purging, etc.

Apart from Indian clients, the machine also drew great attention from visitors from Middle East and Africa. Some new projects were finalized during the fair for various countries in Africa including Nigeria, Kenya, Morocco, Ethiopia and Tanzania.

With a remarkable success in Plast India, Polystar will again be showing its recycling machines in multiple exhibitions including NPE (Orlando) in March 2015 and K show in 2016 among other prominent exhibitions around the world.

Work with POLYSTAR

An experienced market leader in the recycling field, especially for the recycling of packaging film

More than 1,700 Polystar plastic recycling machines have been installed worldwide since 1988

Proven success and positive feedback from satisfied customers in 105 countries

Flexible, personalized machine design to meet your specific requirement and factory layout

Top quality components used for the machines: Energy saving and high performance motors

Cost-effective machine: Lower investment cost for a high quality and durable machine

Service and Communication

Fast online trouble shooting