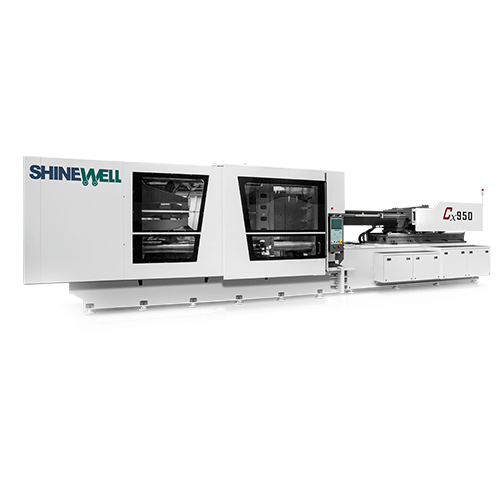

Máquina de moldeo por inyección con ahorro de energía servo CX-60 - CX-1600

CATEGORÍAS : Máquinas de Inyección Horizontal

APLICACIONES: Embalaje, Óptica, Electrónica, Preformas de PET, Cierres, Cubiertos, Pared Delgada, Automotriz

Vertical Two Tie-Bar Injection Molding Machine

CATEGORÍAS : Máquinas de Inyección con Cierre Hidráulico

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production, then reduce the cost of production. High precision mold platen (Parallelism/flatness:0.01/100mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact, space-saving design, reduce the heavy burden of the floor of factory.

Vertical Single Shuttle Table Injection Machine

CATEGORÍAS : Máquinas de Inyección Vertical

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

Vertical Shuttle Table Injection Molding Machine

CATEGORÍAS : Máquinas de Inyección Vertical

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.02/100 mm), heavy duty tie-bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

Custom Vertical LIM LSR Injection Moulding Machine

CATEGORÍAS : Máquinas de Inyección Vertical

Precision vertical clamping system (parallelism/ flatness : 0.02/100mm) , heavy-duty tie-bars, and low-pressure mold clamping work together to greatly extend machine & mold life. Increased productivity and efficiency with shuttle table or rotary table configuration. Pick and place products while another product finsihes molding. Energy savings of around 50-70% with servo pump power system. Safety cover, Light curtain, pneumatic door and dual palm safety button for personnel safeguard. Multi-Language PC Base industrial type Linux core system. 1000 sets of mold settings can be stored and export as backup. Complete record of history settings & warnings. Built in USB connect. On-line remote control and maintenance service.

Vertical 4-TIE BAR Injection Machine

CATEGORÍAS : Máquinas de Inyección con Cierre Hidráulico

Vertical direct hydraulic clamping system is designed for accurate, safe operation, especially suitable for insert molding. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , then reduce the cost of production. High precision mold platen ( Parallelism / flatness : 0.01/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitride and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, reduce the heavy burden of the floor of factory.

C Type Injection Molding Machine

CATEGORÍAS : Máquinas de Inyección Vertical

Tie-bar less (C type) design gives more space for operation. Especially suitable for the power cord and connector with wire. With double slide table or rotary design, put in, takeout products and molding finish at the same time, which is more safe and efficient for production , thus reduce the cost of production. High precision mold platen ( Parallelism/ flatness : 0.01/100 mm), heavy duty tie bars, and low pressure mold clamping work together to greatly extend machine & mold life. Nitrite and NIP/ Nitroflon coated screws and barrels are long-lasting, robust and provide superior acid/alkaline resistance. Heavy-duty double cylinder injection unit is maintenance friendly and free of oil leaks. All series adapted Variable pump +PQ valves enable energy savings of 30~50%. Proportional hydraulic control system provides low noise, low energy consumption, and smooth machine movements with durable life. Low oil temperature, durable parts, high speed injection, and quiet operation. Controller can record the production conditions such as temperature, pressure, flow, position available on the panel, reducing adjust of machine. All machine with compact , space-saving design, resolve the floor space shortage problem of factory. Material injected through parting line to cavities.

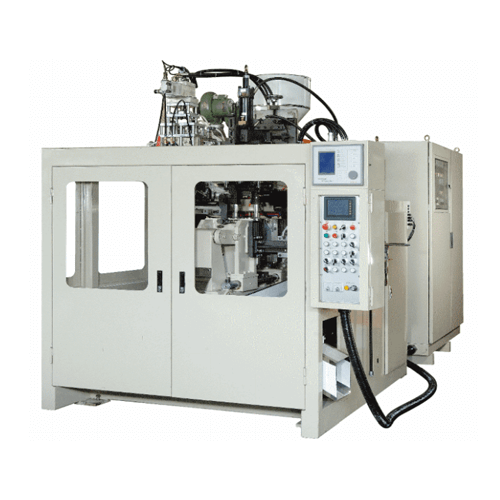

JN Series-Single Station

CATEGORÍAS : Máquinas automáticas de moldeo por soplado

● Tipo hidráulico Máquina de moldeo por soplado automática. ● Diseño de producción automático. ● Diseño de estructura de sujeción de servicio pesado. ● Molde Abrir / Cerrar / Mover por guía lineal de precisión y las botellas terminadas salen en línea para el siguiente proceso. ● Extrusora de transmisión directamente. ● Los desechos centralizan la gestión. ● Control PLC con pantalla táctil para tiempo, presión, flujo, ... etc. ● Las cuchillas de parison diversificadas y las opciones de cabezales múltiples dependen del requisito. ● Sistema de ahorro de energía para el sistema hidráulico.

MÁQUINA DE MOLDEO POR SOPLADO DE PET STRETCH-TEM08SH2

CATEGORÍAS : Máquinas automáticas de moldeo por soplado

Ahorro económico y energético en comparación con otras máquinas cristalizadas. Puede ahorrar hasta un 50% de energía. Mediante rueda de estrella, estable y suave al sistema de transporte.

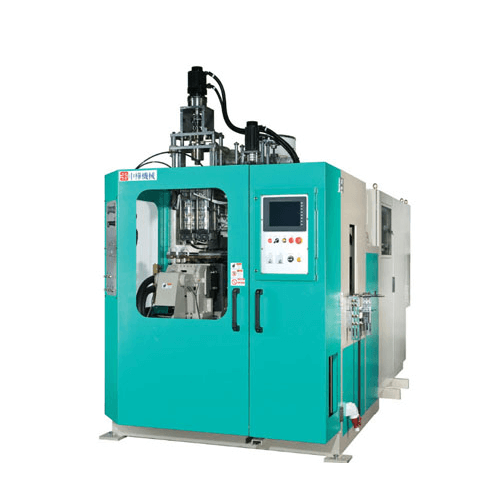

JH Series-Single Station

CATEGORÍAS : Máquinas automáticas de moldeo por soplado

● Suministrar todo tipo eléctrico y máquina de moldeo por soplado de tipo híbrido. ● Mucho menos ruido. ● Se redujo el costo de mantenimiento y tiempo. ● Alta calidad de producción estable. ● Ahorre más del 72% de energía. (para correr 24 horas)

JH Series-Double Station

CATEGORÍAS : Máquinas automáticas de moldeo por soplado

● Suministrar todo tipo eléctrico y máquina de moldeo por soplado de tipo híbrido. ● Mucho menos ruido. ● Se redujo el costo de mantenimiento y tiempo. ● Alta calidad de producción estable. ● Ahorre más del 72% de energía. (para correr 24 horas)

MÁQUINA DE MOLDEO POR SOPLADO DE PET STRETCH-TEM08M3

CATEGORÍAS : Máquinas automáticas de moldeo por soplado

CARACTERÍSTICA Adopte el sistema de control de pantalla táctil con color de 64K y un funcionamiento sencillo del PLC. La construcción de la máquina de diseño exclusivo hace que sea conveniente combinar la máquina de moldeo por soplado con el sistema de transporte. Las preformas se disponen automáticamente para alimentar el sistema de una sola vía y el portador divisor es accionado por un servomotor; de esta forma evitará que las preformas se atasquen, lo que provocaría que la máquina se cayera o que las preformas se desperdiciaran. Adopte un sistema de accionamiento de tornillo de servocontrol; es rápido, estable, limpio y ecológico. Las preformas se introducen en el sistema de calefacción en modo matricial y se calientan uniformemente mediante una lámpara con calefacción de doble cara. Emplee una lámpara única con diseño de calefacción de doble cara y ahorrará aproximadamente un 50% en el consumo de calefacción en comparación con el método de la competencia. Con la función de retroalimentación de temperatura, la temperatura en el horno de calentamiento se controla automáticamente mediante el ajuste de las lámparas infrarrojas para reducir los problemas de cristalización previa. La caja de calefacción especialmente diseñada mejora la conveniencia de mantenimiento al cambiar la lámpara infrarroja y la rampa de enfriamiento. El mecanismo de sujeción es impulsado por una combinación de servomotor y leva; esto da como resultado un movimiento preciso y estable, bajo nivel de ruido y mínima contaminación. Utiliza el sistema de recuperación de aire y la eficiencia hasta el 50% para que no se requiera el compresor de aire de baja presión. Esto permitirá ahorrar costos de inversión en equipos y consumo de energía hasta en un 15%.